jisangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

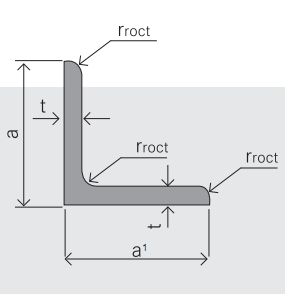

Specifications of GB Q235 Angle Steel

1. Standards: GB,ASTM,BS,AISI,DIN,JIS

2. Invoicing on theoretical weight or actual weight as customer request

3. Material:Material: GB Q235B, Q345B or Equivalent; ASTM A36; EN 10025, S235JR, S355JR; JIS G3192, SS400;

SS540.

4. Sizes:

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of GB Q235 Angle Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of GB Q235 Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

- Q: Where can you buy steel angles?

- There are various places where you can purchase steel angles. One possibility is to pay a visit to a local hardware or building supply store. These establishments usually have a wide selection of construction materials, which includes steel angles, that you can buy. Moreover, you can also inquire with metal suppliers or steel fabricators in your vicinity. They typically specialize in the sale of steel products, including angles, and can offer you a variety of choices to select from. Another option is to explore online marketplaces and industrial supply websites. These platforms present a convenient means to browse and purchase steel angles from a range of suppliers, often with the added benefit of being able to compare prices and read customer reviews. Whether you have a preference for shopping in person or online, there are numerous options available to fulfill your specific requirements for purchasing steel angles.

- Q: Can steel angles be painted or coated for aesthetic purposes?

- Steel angles can indeed be painted or coated to improve their appearance and shield them from corrosion. Typically, this entails cleaning the surface of the steel angles to eliminate any dirt, oil, or rust, followed by applying a primer and paint or a specialized coating. The selection of paint or coating will vary based on the desired aesthetic and the environmental conditions the steel angles will encounter. Through the process of painting or coating steel angles, they can be personalized to complement the surrounding decor or architectural design, resulting in a more visually attractive appearance that seamlessly harmonizes with the overall aesthetic.

- Q: Can steel angles be used for modular construction?

- Yes, steel angles can be used for modular construction. Steel angles are commonly used in construction for their strength, versatility, and cost-effectiveness. In modular construction, steel angles can be used to create frames, support structures, and connections between modules. They provide stability and structural integrity to the modular units, ensuring durability and safety. Additionally, steel angles can be easily fabricated and customized to suit the specific design requirements of modular construction projects. Overall, steel angles are a viable and commonly used material in modular construction due to their numerous benefits and suitability for the construction process.

- Q: What are the common sizes of steel angles?

- The common sizes of steel angles can vary depending on the industry and specific requirements of a project. However, there are several standard sizes that are commonly used. In the United States, the most commonly available steel angles come in widths of 1/2 inch, 1 inch, 1-1/2 inches, and 2 inches. These angles typically have thicknesses ranging from 1/8 inch to 1/4 inch. In addition to these standard sizes, larger and smaller angles can also be found, typically used for specialized applications. These may include wider angles up to 8 inches or more, or thinner angles with thicknesses as low as 1/16 inch. It is important to note that these sizes may vary in different countries or regions, and suppliers may have their own specific range of sizes available. Therefore, it is recommended to consult with local suppliers or manufacturers to determine the most common sizes of steel angles in a particular area.

- Q: How do you determine the strength of a steel angle?

- The strength of a steel angle can be determined by considering its dimensions, material properties, and the load it will be subjected to. Factors such as the thickness and width of the angle, as well as the type and grade of steel used, play a crucial role in its strength. Additionally, analyzing the applied load, whether it's a tensile, compressive, or bending force, helps assess the angle's strength based on its ability to withstand and distribute the load without failure. Various mathematical calculations and engineering standards can be used to determine the strength of a steel angle in specific applications.

- Q: Can steel angles be used for reinforcement in concrete structures?

- Yes, steel angles can be used for reinforcement in concrete structures. Steel angles, also known as L-shaped steel profiles, are commonly used as reinforcing bars in concrete construction. They provide increased strength and stability to the concrete structure, especially in areas where additional support is needed. Steel angles are typically placed within the concrete forms, ensuring proper alignment and spacing, and then embedded in the concrete during the pouring process. This reinforcement helps to prevent cracking and enhance the overall structural integrity of the concrete structure. Steel angles are versatile and can be used in various concrete applications, such as beams, columns, walls, and slabs.

- Q: How are steel angles tested for quality and strength?

- Steel angles are tested for quality and strength through various methods to ensure they meet the required standards and specifications. One of the primary tests conducted on steel angles is the tensile test, which measures the material's resistance to breaking under tension. This test involves applying a gradually increasing load to a sample of the steel angle until it reaches its breaking point. The maximum load the angle can withstand is measured, and this provides critical information about its tensile strength. Another important test is the hardness test, which determines the steel angle's resistance to indentation. This test helps to assess the material's ability to withstand wear and tear, as well as its overall strength. Hardness is typically measured using the Rockwell or Brinell scales, where a harder material indicates higher strength. To ensure the steel angle's quality, it also undergoes visual inspections for any surface defects, such as cracks, uneven surfaces, or deformities. These inspections are conducted by trained professionals who carefully examine the angles for any imperfections that may compromise their structural integrity. In addition to these tests, steel angles may also undergo chemical composition analysis to verify that the material meets the required specifications. This analysis determines the percentage of various elements present in the steel, such as carbon, manganese, and sulfur, which directly impact the angle's strength and durability. Overall, steel angles are rigorously tested for quality and strength through a combination of physical, visual, and chemical tests. These tests ensure that the angles can withstand the intended loads and perform safely in various applications, providing confidence in their reliability and longevity.

- Q: What are the different types of steel angles used in storage systems?

- There are several different types of steel angles that are commonly used in storage systems. These angles play a crucial role in providing structural support and stability to the storage racks. Here are some of the most commonly used steel angles in storage systems: 1. Equal angle: This type of angle has equal sides and is commonly used in storage systems to create sturdy frames and supports. Equal angles are often used for the uprights and beams in pallet racking systems. 2. Unequal angle: As the name suggests, unequal angles have sides of different lengths. They are often used in storage systems to accommodate specific design requirements where different load capacities or dimensions are needed. 3. Slotted angle: Slotted angles have holes along their length, allowing for easy adjustability and flexibility in storage system design. These angles are popular in DIY storage projects and can be easily cut and bolted together to create customized storage solutions. 4. L-shaped angle: L-shaped angles, also known as corner angles or corner brackets, are used to reinforce the corners of storage racks and provide extra strength and stability. They are typically used in combination with other angles to create sturdy connections. 5. Rolled steel angle: Rolled steel angles are produced by rolling a flat steel strip into an L-shaped angle. They are commonly used in storage systems where high load-bearing capacity and durability are required. Rolled steel angles are often used in heavy-duty industrial storage applications. These are just a few examples of the different types of steel angles used in storage systems. The specific type of angle used will depend on factors such as the load capacity, design requirements, and the specific needs of the storage system.

- Q: How do steel angles resist bending or deflection?

- Steel angles are able to resist bending or deflection because of their shape and material properties. The L-shaped cross-section of steel angles contributes to their structural stability and strength, resulting in a high resistance to bending or deflection under load. The L-shape of steel angles creates two legs that are perpendicular to each other. This design allows for a more efficient distribution of the applied load compared to other shapes. As a result, the angles are able to resist bending forces, preventing significant deformation or deflection. The longer leg of the angle provides greater leverage and stiffness, further enhancing its resistance to bending. In addition to the shape, steel itself is a strong and rigid material known for its high tensile and compressive strength. Steel angles are typically made from hot-rolled steel, which undergoes a process that improves its structural properties. The combination of the L-shape design and the inherent strength of steel enables steel angles to withstand bending forces without significant deflection. Furthermore, steel angles can be reinforced through methods such as welding or bolting to increase their resistance to bending or deflection. These reinforcements add extra strength and stiffness to the angles, making them even more robust and capable of handling higher loads. To summarize, steel angles resist bending or deflection due to their L-shape design, the inherent strength of steel, and possible reinforcements. These factors work together to provide structural stability and prevent excessive deformation, making steel angles a reliable choice for various construction and engineering applications.

- Q: Can steel angles be used in overhead crane or hoist systems?

- Yes, steel angles can be used in overhead crane or hoist systems. Steel angles are commonly used in the construction of crane runways, support structures, and trolley rails. They provide a strong and rigid framework for the crane or hoist system. Steel angles are known for their high strength-to-weight ratio, making them an ideal choice for heavy-duty applications. Additionally, steel angles can be easily welded or bolted together, allowing for easy installation and customization. Overall, steel angles are a reliable and cost-effective option for incorporating into overhead crane or hoist systems.

Send your message to us

jisangle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords