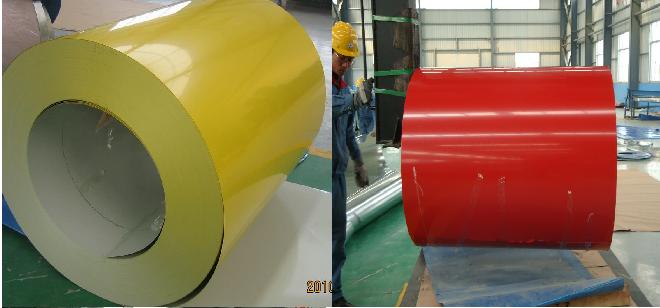

JIS G3312/ASTM A755 Prepainted Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,JIS | Grade: | CGCC | Thickness: | 0.20mm to 1.20mm |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | HZZN | Model Number: | PPGI0303 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Galvanized |

| Application: | home appliance | Special Use: | Silicon Steel | Width: | 914/1000/1219/1200/1250mm |

| Length: | in coil | Single coil weight: | 4-6mt | Inner diameter: | 508mm or 610mm |

| Color paint coated: | top:15-25um,back:5-10um | Color: | according to RAl card | International export market: | North America, South America,Europe, Africa, Oceania, Mid East and etc |

| HS code: | 72107000 |

Packaging & Delivery

| Packaging Detail: | standard export seaworthy package. wrapped by plastic film and waterproof paper, and then fastened on wooden pallet.Or according to clients' requirement. |

| Delivery Detail: | 20-25 days after receive T/T deposit or L/C |

Specifications

1>Thickness:0.2-1.2mm

2>Zinc coating: 60-275gr/m2

3>Paint coating : 5+25um (top), 5-8um (back)

4>Paint:Beckers

5>Color:RAL

Description:

Products | JIS G3312/ASTM A755 Prepainted Steel Coil To European Union Market Without Anti-Dumping Tax |

Width | 914/1000/1219/1200/1250mm or accoding to clients' requirement |

Thickness | 0.20 ---1.20mm |

I.D. | 508mm/610mm |

Weight Per Coil | 4-6tons |

Paint Brand | Beckers |

Paint Thickness | 15-25micron at top,5-10micron at reverse |

Zinc coating | 40-275g/m2 |

Standard | ASTM A755M/JIS G3312 |

Steel grade | CGCC |

Usage | home appliance,building materials,roof system,etc. |

MOQ | 25 tons |

Quality | approved by SGS |

Productivity | 100,000 Metric ton / year |

Key to success | advanced technique and good service and low price |

Authentification | ISO9001:2008 |

Market | North/South America, Europe, Asia,Africa,Mid East,ect. |

Packaging | wrapped by plastic film and waterproof paper, and then fastened on wooden pallet.Or according to clients' requirement. |

Port | Shanghai or Ningbo |

Delivery term | FOB / CIF/ CFR |

Delivery time | In 20-25 days after receipt of deposit or L/C |

Payment term | 30%T/T down payment,balance before shipment or irrevocable L/C at sight |

- Q: Ok I know this sounds stupid but is there anyway to make stainless steel look older? It looks too new and I don't want it like that. Thanks.

- Its called stainless for a reason :) many grades are out there, 300 400 series. You could use acid to make it look older but you wouldnt want to cook with it after chemically converting it with acid.Personally i like cast iron. It will last a life time + and looks very cool. Sorry no safe way to do it and cook with it. B^

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- What exactly are you using it for? Personally I would go with Cold Steel AK47. It's a good all around knife for hunting, combat, stabbing and slashing as well as everyday use. Well balanced tip and very little bladeplay which can be a problem with a cheaper knife. Both are good companies but the CS AK47 wins hands down for me.

- Q: Suppose you made a sword out of diamond (just follow me here, it's only theoretical). Would it be lighter than a sword of the same size made out of steel?

- The weight of steel is dependent among what kind of steel, shape, length, width, thickness a 5mm by 5mm ball of carbon steel would wiegh 1.69969 g a same size diamond weighs .79 carats equivelent to 1.5 grams So the basic answer is, yes, diamond is lighter than steel, but barely

- Q: How can defects in steel coils be detected?

- Defects in steel coils can be detected through various non-destructive testing methods such as visual inspection, ultrasonic testing, magnetic particle inspection, eddy current testing, and radiographic testing. These techniques help identify surface cracks, internal flaws, irregularities in thickness, and other defects, ensuring the quality and integrity of the steel coils.

- Q: What are the different types of surface finishes for steel coils?

- There are several different types of surface finishes for steel coils, each offering its own unique properties and advantages. Some of the most common surface finishes for steel coils include: 1. Hot Rolled: This is the most basic surface finish for steel coils and is achieved by heating the steel and then rolling it to its final shape. It typically has a rough and scale-like appearance, with varying levels of surface imperfections. 2. Cold Rolled: This surface finish is achieved by further processing hot rolled steel coils through a series of cold rolling operations. Cold rolled steel has a smoother and more uniform surface compared to hot rolled steel, with improved dimensional accuracy and better surface quality. 3. Galvanized: Galvanizing is a process in which a protective layer of zinc is applied to the surface of the steel coil. This surface finish provides excellent corrosion resistance, making it ideal for outdoor applications and environments where the steel is exposed to moisture and other corrosive elements. 4. Stainless Steel: Stainless steel coils have a unique surface finish due to the presence of chromium, which forms a thin, invisible layer of oxide on the surface. This surface finish provides excellent corrosion resistance and a visually appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this surface finish involves the application of a thin layer of zinc to the steel coil through an electroplating process. It provides good corrosion resistance and is commonly used in applications where aesthetics are important. 6. Pre-painted: Pre-painted steel coils have a surface finish that is coated with a layer of paint or other protective coatings. This finish offers both corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes to be applied. 7. Aluminized: Aluminized steel coils have a surface finish that is coated with a layer of aluminum-silicon alloy. This finish provides excellent heat resistance and is commonly used in applications where high temperatures are encountered, such as exhaust systems or ovens. Overall, the choice of surface finish for steel coils depends on the specific requirements of the application, including factors such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: Why cold rolled stainless steel sheet is lower than cold rolled stainless steel coil?

- 304 stainless steel coil 2.0*1219*C spot price 18 thousand and 100 / ton, general tolerance at about 1.8mm.Coil price * actual thickness / reference thickness = flat price1.81*1.8/2=16.29

- Q: Can steel coils be coated with electrically conductive materials?

- Yes, steel coils can be coated with electrically conductive materials.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Painting a piece of steel will coat it with a protective layer, causing it to not rust (not get oxidised). Aluminum does not rust.

- Q: How are steel coils used in the manufacturing of chassis frames?

- Steel coils are used in the manufacturing of chassis frames by being processed and formed into specific shapes and dimensions. The coils are first uncoiled and then passed through various machines to cut, bend, and weld them into the desired frame structure. This process ensures that the chassis frame is strong, durable, and able to withstand the demands of a vehicle's weight and functionality.

- Q: I like non-stick cookware but it dont hold up no matter how much money you spend. What isthe best kind? Is there something better then stainless steel or iron skillet? I do not care if I have to use extra elbow grease to clean a pan.

- Some utensils are both cookware and bakeware. The choice of material for cookware and bakeware items has a significant effect on the item's performance , particularly in terms of thermal conductivity and how much food sticks to the item when in use. Some choices of material also require special pre-preparation of the surface - known as seasoning - before they are used for food preparation. Stainless steel cookware is a great choice for safe cooking. Many kinds of cookware react with the foods, either changing the taste of the food or even releasing harmful materials into the food that can cause imbalances or diseases. Many non-stick coatings like teflon are safe - but once they get scratched or overheated they can start to leak chemicals in the food that are according to some scientific studies dangerous and possibly carcinogenic. Both the cooking pot and lid handles can be made of the same material, but will mean that when picking up or touching either of these parts oven gloves will need to be worn. In order to avoid this, handles can be made of non heat conducting materials, for example bakelite, plastic or wood. It is best to avoid hollow handles because they are difficult to clean or to dry.

Send your message to us

JIS G3312/ASTM A755 Prepainted Steel Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords