Japanese Standard SS400 H beam with High Quality 340mm-396mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

1. Standard: JIS 3192

2. Grade: SS400 or Equivalent

3. Length: 10m, 12m as following table

4. Invoicing on theoretical weight or actual weight as customer request

5.Payment: TT or L/C

Size and Mass of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

| Size(mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 340*250*9.0 | 78.1 | 350*350*12.0 | 135 |

| 344*348*10.0 | 113 | 396*199*7.0 | 56.1 |

Packaging & Delivery of Japanese Standard SS400 H beam with High Quality 340mm-396mm for Building Structures:

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Delivered by container or bulk vessel

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 months from the beginning of production.

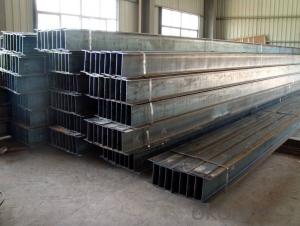

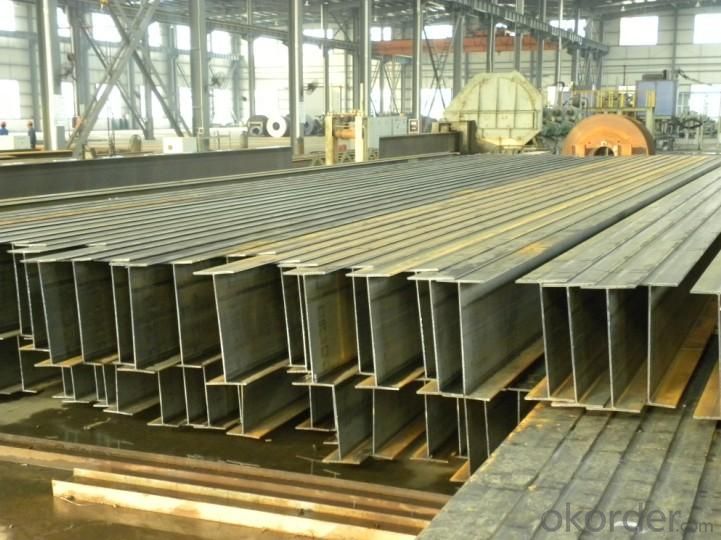

Images of Japanese Standard SS400 H beam with High Quality 340mm-396mm:

* If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention

- Q: How are steel H-beams different from other types of beams?

- H-sections, also called Steel H-beams, possess distinct qualities and shape that set them apart from other beams. Their specific cross-sectional shape, resembling the letter "H," grants them significant advantages over alternative beam types. To begin with, the shape of the H-beam allows it to bear a greater load compared to beams of similar weight. This is due to the even weight distribution along its length, maximizing its ability to withstand heavy loads. Consequently, H-beams find extensive use in construction projects that demand robust and enduring structural support, such as high-rise buildings, bridges, and industrial facilities. Moreover, H-beams provide enhanced structural stability. The flanges, which are the top and bottom horizontal sections of the H-beam, offer resistance against bending and twisting forces. This characteristic makes H-beams less prone to deformations and enables them to maintain their shape under heavy loads. Additionally, the web, or vertical section of the H-beam, offers supplementary support and rigidity, ensuring overall stability in the structure. Another notable advantage of H-beams lies in their versatility. With their inherent strength and stability, H-beams can span longer distances without requiring intermediate supports. This enables the creation of larger open spaces and more flexible architectural designs. Furthermore, H-beams can be easily welded together, allowing for the creation of longer beams and expanding their range of applications. Lastly, H-beams offer cost-effectiveness. Despite their robustness, H-beams are comparatively lightweight in relation to their load-bearing capacity. This reduces transportation costs and simplifies the installation process, making them a cost-effective option for construction projects. In conclusion, Steel H-beams stand out from other beam types due to their unique cross-sectional shape. This shape provides advantages in terms of increased load-bearing capacity, structural stability, versatility, and cost-effectiveness. These characteristics make H-beams the preferred choice for various construction applications where strength, durability, and efficiency are crucial factors.

- Q: Can steel H-beams be used for industrial structures?

- Yes, steel H-beams can be used for industrial structures. H-beams offer great strength and durability, making them suitable for supporting heavy loads and withstanding various environmental conditions. They are commonly used in construction projects for warehouses, factories, and other industrial facilities.

- Q: Can steel H-beams be used in the construction of power plants?

- Certainly! Steel H-beams are indeed suitable for power plant construction. These beams are widely utilized in the field of construction due to their strength, durability, and versatility. They offer structural support and stability, making them appropriate for a variety of applications within power plants. In the construction of power plant buildings, steel H-beams can be employed to support heavy machinery and equipment, as well as serve as the structural framework for the plant's infrastructure. Moreover, steel H-beams possess a remarkable load-bearing capacity and can withstand high temperatures, making them highly suitable for power plant environments. Consequently, steel H-beams are a dependable and frequently employed material in the construction of power plants.

- Q: Can steel H-beams be used for supporting roller coasters or amusement park rides?

- Yes, steel H-beams can be used for supporting roller coasters or amusement park rides. Steel H-beams are commonly used in construction due to their strength, durability, and ability to bear heavy loads. Roller coasters and amusement park rides require sturdy support structures, and steel H-beams provide the necessary strength and stability to ensure the safety and stability of these attractions.

- Q: What are the different fire protection methods for steel H-beams?

- There are several fire protection methods available for steel H-beams to ensure their structural integrity and prevent them from collapsing during a fire. These methods include: 1. Intumescent Coatings: Intumescent coatings are applied to the surface of the steel beams. When exposed to high temperatures, these coatings expand and form a thick insulating char layer, which protects the steel from heat and slows down its temperature rise. 2. Cementitious Coatings: Cementitious coatings are commonly used for fire protection in steel structures. These coatings consist of a mixture of cement, aggregates, and fibers. They provide a barrier against heat transfer and can withstand high temperatures. 3. Fireproofing Sprays: Fireproofing sprays are a cost-effective method for protecting steel beams. These sprays typically contain a combination of fire-resistant materials and are applied as a thick layer onto the beams. The spray forms an insulating barrier that delays the transfer of heat to the steel. 4. Encasement with Concrete: Another method is to encase the steel H-beams in concrete. This provides excellent fire protection as concrete has a high fire resistance. The concrete acts as a thermal barrier and prevents the steel from reaching critical temperatures. 5. Gypsum Board Encasement: Gypsum board encasement involves covering the steel beams with multiple layers of gypsum board. These boards are fire-resistant and provide a protective covering for the steel. This method is commonly used in buildings where aesthetics are important. It is important to note that the choice of fire protection method depends on factors such as the fire rating requirements, architectural design, and budget. Consulting with fire protection experts and complying with local building codes and regulations is crucial to ensure the appropriate fire protection method is chosen for steel H-beams.

- Q: What are the transportation considerations for steel H-beams?

- Transportation considerations for steel H-beams primarily revolve around their size, weight, and safety requirements. Firstly, the size of steel H-beams is an important consideration for transportation. These beams are typically large and bulky, ranging in length from a few meters to over 20 meters. As a result, special transport arrangements may be necessary, such as using flatbed trucks, trailers, or even railcars, depending on the distance and infrastructure available. Additionally, the width and height of the beams may require special permits or escorts during transportation to ensure compliance with road regulations. Secondly, the weight of steel H-beams is a crucial factor. These beams can weigh several tons, depending on their size and dimensions. Therefore, it is important to ensure that the transportation equipment, including the vehicles and lifting apparatus, can handle the weight safely. Specialized cranes or forklifts may be required to load and unload the beams at both the pickup and delivery locations. Safety is another critical consideration when transporting steel H-beams. Due to their size and weight, proper securing and bracing techniques should be employed to prevent shifting or tipping during transit. This may involve using chains, straps, or other restraints to secure the beams to the transport vehicle or container. Additionally, the beams should be adequately protected from the elements, such as rain or snow, to prevent corrosion or damage during transportation. Finally, logistical considerations should be taken into account. This includes determining the most efficient route for transportation, considering factors such as road conditions, weight restrictions, and traffic congestion. It may also involve coordinating delivery schedules to ensure that the beams arrive at the desired location within the required timeframe. Overall, the transportation considerations for steel H-beams involve managing their size, weight, safety, and logistics to ensure a successful and efficient delivery.

- Q: How do you calculate the deflection limits for steel H-beams?

- To determine the deflection limits for steel H-beams, several factors must be considered. Typically, the deflection limits are established by relevant building codes or industry standards. The steps below outline the general process of calculating these limits: 1. Find the applicable building code or industry standard: Building codes or industry standards, such as the American Institute of Steel Construction (AISC) code, usually specify the deflection limits. These codes provide guidelines based on the intended use of the structure. 2. Gather information about the H-beam: Collect the necessary details about the H-beam, including dimensions, material properties, and support conditions. This information can be obtained from the manufacturer or relevant design resources. 3. Calculate the moment of inertia: The moment of inertia measures the beam's resistance to bending. It is determined by the beam's dimensions and geometry. The moment of inertia plays a critical role in determining the deflection of the beam. 4. Identify the applied load: Determine the load or loads that will act on the H-beam. This may include dead loads, live loads, wind loads, or other specified loads according to design requirements. 5. Use the appropriate deflection formula: The choice of deflection formula depends on the type of loading and support conditions. Common formulas include the Euler-Bernoulli beam equation, which assumes linear elastic behavior, and the Timoshenko beam equation, which considers shear deformations. 6. Calculate the maximum allowable deflection: Utilize the deflection formula to input relevant parameters such as applied load, beam properties, and support conditions. Calculate the deflection at various points along the beam and compare these values to the deflection limits specified in the building code or industry standard. 7. Ensure compliance with deflection limits: If the calculated deflection exceeds the specified limits, adjustments must be made to the beam's dimensions, material, or support conditions. This may involve increasing the beam size, using a stronger material, or adding additional support. It is important to note that calculating deflection limits for steel H-beams can be a complex process that may require the expertise of a structural engineer or designer. Adhering to the applicable building codes and industry standards is crucial to ensure project safety and structural integrity.

- Q: Are steel H-beams suitable for coastal areas with high salt content in the air?

- Steel H-beams are generally suitable for coastal areas with high salt content in the air. However, they may be more prone to corrosion due to the presence of salt. To ensure their longevity, it is important to use corrosion-resistant coatings or materials, perform regular maintenance, and consider the specific environmental conditions of the coastal area.

- Q: What is the lifespan of steel H-beams?

- Several factors can influence the lifespan of steel H-beams, including the quality of the steel, usage conditions, and maintenance levels. Generally, steel H-beams are designed for durability and can be used in various structural applications. If manufactured and maintained correctly, steel H-beams can last for several decades or even longer. Steel's high strength and structural integrity enable it to endure heavy loads, harsh weather conditions, and other external factors that may degrade the material over time. However, it is crucial to consider that several factors can contribute to the deterioration of steel H-beams. These factors include exposure to corrosive elements like moisture, chemicals, and saltwater, as well as structural overload, excessive vibrations, and improper installation or handling. Regular inspections and maintenance play a significant role in identifying signs of corrosion, fatigue, or structural damage that could affect the beams' lifespan. In conclusion, the lifespan of steel H-beams can be extensive if they are manufactured properly, maintained correctly, and used within their design limitations. By implementing appropriate maintenance practices and safeguarding the beams from adverse conditions, it is possible to significantly extend their lifespan.

- Q: Are steel H-beams resistant to pests and termites?

- Yes, steel H-beams are highly resistant to pests and termites. Unlike wood, which is susceptible to termite infestation and damage, steel beams provide a strong and durable alternative. Termites are unable to feed on or damage steel, making it an ideal choice for construction projects in areas prone to termite infestation. Additionally, steel does not provide a suitable environment for other pests, such as rodents, to inhabit or cause damage. Therefore, steel H-beams offer long-term protection against pest infestation, making them a reliable choice for structural support in buildings and other construction applications.

Send your message to us

Japanese Standard SS400 H beam with High Quality 340mm-396mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords