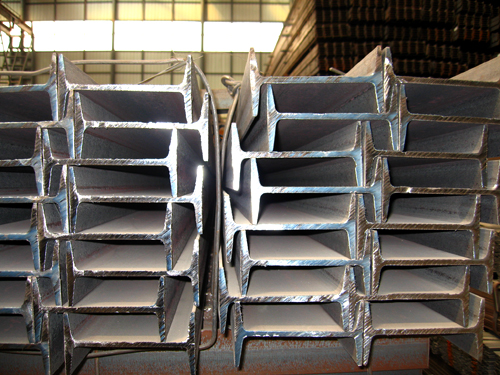

Hot Rolled Steel I-Beam with good quality from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Steel I-Beam with good quality from china at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Steel I-Beam with good quality from china applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Steel I-Beams are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: Q195 – 235

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Chinese Standard (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light I (H*W*T) | Weight (Kg/m) | 6m (pcs/ton) | Light II (H*W*T) | Weight (Kg/m) | 6M |

100*68*4.5 | 11.261 | 14.8 | 100*66*4.3 | 10.13 | 16.4 | 100*64*4 | 8.45 | 19.7 |

120*74*5.0 | 13.987 | 11.9 | 120*72*4.8 | 12.59 | 13.2 | 120*70*4.5 | 10.49 | 15.8 |

140*80*5.5 | 16.89 | 9.8 | 140*78*5.3 | 15.2 | 10.9 | 140*76*5 | 12.67 | 13.1 |

160*88*6 | 20.513 | 8.1 | 160*86*5.8 | 18.46 | 9 | 160*84*5.5 | 15.38 | 10.8 |

180*94*6.5 | 24.143 | 6.9 | 180*92*6.3 | 21.73 | 7.6 | 180*90*6 | 18.11 | 9.2 |

200*100*7 | 27.929 | 5.9 | 200*98*6.8 | 25.14 | 6.6 | 200*96*6.5 | 20.95 | 7.9 |

220*110*7.5 | 33.07 | 5 | 220*108*7.3 | 29.76 | 5.6 | 220*106*7 | 24.8 | 6.7 |

250*116*8 | 38.105 | 4.3 | 250*114*7.8 | 34.29 | 4.8 | 250*112*7.5 | 28.58 | 5.8 |

280*122*8.5 | 43.492 | 3.8 | 280*120*8.2 | 39.14 | 4.2 | 280*120*8 | 36.97 | 4.5 |

300*126*9 | 48.084 | 3.4 | 300*124*9.2 | 43.28 | 3.8 | 300*124*8.5 | 40.87 | 4 |

320*130*9.5 | 52.717 | 3.1 | 320*127*9.2 | 48.5 | 3.4 | |||

360*136*10 | 60.037 | 2.7 | 360*132*9.5 | 55.23 | 3 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Images:

- Q: Are steel H-beams resistant to mold and mildew?

- Mold and mildew growth is not a common problem with Steel H-beams. Mold and mildew need organic materials, like wood or fabric, to thrive, which are often found in building materials such as drywall or insulation. Unlike these materials, steel is inorganic and does not provide a suitable environment for mold and mildew to grow. Moreover, steel H-beams are frequently used in structural applications where moisture is effectively managed and controlled, minimizing the chances of mold and mildew growth. It is worth noting, however, that if steel H-beams are exposed to excessive moisture or placed in high humidity areas, condensation may form on their surfaces. Although this won't directly cause mold and mildew growth on the steel itself, it could create a damp atmosphere that indirectly promotes the growth of mold and mildew on nearby materials. Therefore, it is crucial to implement proper measures for moisture control and ventilation in order to prevent any potential issues.

- Q: How do steel H-beams perform in terms of impact resistance?

- Steel H-beams are known for their excellent impact resistance. The structural design of H-beams, with their wide flanges and vertical web, allows for a high level of durability and strength when subjected to impact forces. This makes them particularly suitable for applications where there is a risk of heavy loads or potential impact, such as in construction projects or industrial settings. The wide flanges of H-beams distribute the impact load over a larger area, helping to minimize the concentrated stress points and prevent failure. Additionally, the vertical web provides added rigidity and stability, enhancing the overall impact resistance of the beam. Furthermore, steel as a material has inherent toughness and resilience, enabling it to absorb and dissipate energy from impacts. Steel H-beams are often fabricated from high-quality structural steel, which further enhances their impact resistance properties. In summary, steel H-beams exhibit excellent performance in terms of impact resistance due to their structural design and the material properties of steel. They are able to withstand heavy loads and potential impacts, making them a reliable choice for various applications requiring structural strength and durability.

- Q: How are steel H-beams specified in construction drawings?

- Steel H-beams are specified in construction drawings by providing detailed information about their dimensions, such as the height, width, and thickness of the flanges and web, as well as the overall length. The drawings also include information about the steel grade, tolerances, and any specific requirements for welding or connections. Additionally, the drawings may indicate the location and orientation of the H-beams within the structure, along with any necessary details or notations for installation.

- Q: Can steel H-beams be used in high-rise buildings?

- Indeed, high-rise buildings can make use of steel H-beams. These beams are frequently employed as structural components within the construction sector owing to their exceptional strength and adaptability. They possess the ability to endure substantial loads and are frequently utilized to bear the weight of floors, walls, and roofs in tall buildings. The distinctive H shape of these beams offers a larger surface area for distributing the load, rendering them an optimal selection for structures of great height that experience significant weight and pressure on the beams. Furthermore, steel H-beams can be effortlessly fabricated, affording efficient construction procedures in high-rise buildings.

- Q: Can steel H-beams be used for temporary structures?

- Yes, steel H-beams can be used for temporary structures. They provide excellent structural support and stability, making them suitable for various temporary applications such as construction scaffolding, temporary stages, and event structures.

- Q: Can steel H-beams be used for residential garages?

- Yes, steel H-beams can be used for residential garages. H-beams are commonly used in construction due to their strength and durability. They provide excellent structural support, making them suitable for applications such as garage construction. Steel H-beams offer several advantages, including resistance to bending and warping, which ensures the stability of the garage structure. Additionally, steel H-beams have a high load-bearing capacity, allowing them to support heavy loads such as vehicles and storage items. Using steel H-beams for residential garages can result in a sturdy and long-lasting structure that provides ample protection for your vehicles and belongings.

- Q: What's the difference between hot rolled H steel and welded H? Is it the same weight?

- Stable performance and good internal organization. Due to continuous casting from smelting to rolling, steel production than hot-rolled H steel process requirements, equipment capacity, control level, detection means is high, so the welding of H steel internal organization, chemical composition, various properties (mechanical properties, process performance indicators are reliable and stable etc.).

- Q: What are the different design codes and standards for steel H-beams?

- There are several design codes and standards that govern the use of steel H-beams in construction. Some of the most commonly followed codes and standards include: 1. American Institute of Steel Construction (AISC): AISC 360 is the primary design code for steel structures in the United States. It provides guidelines for the design, fabrication, and erection of structural steel components, including H-beams. AISC 360 incorporates both ASD (Allowable Stress Design) and LRFD (Load and Resistance Factor Design) methods. 2. European Norm (EN): In Europe, steel structures are designed according to the Eurocode standards. Eurocode 3, specifically EN 1993-1-1, contains provisions for the design of steel structures, including H-beams. It provides guidance on the calculation of loads, material properties, and design criteria. 3. British Standards (BS): In the United Kingdom, steel design follows British Standards. BS 5950-1 is the code that covers the design of structural steelwork, including H-beams. It includes provisions for the calculation of loads, material properties, and design principles. 4. Australian Standards (AS): Australia has its own set of design standards for steel structures. AS 4100 is the code that governs the design of steel structures, including H-beams. It provides guidelines for the calculation of loads, material properties, and design principles. 5. Canadian Standards Association (CSA): In Canada, the design of steel structures is regulated by CSA S16, which covers the design of steel members, including H-beams. It includes provisions for the calculation of loads, material properties, and design criteria. These are just a few examples of the various design codes and standards that exist for steel H-beams. It is important to consult the specific code applicable to the country and jurisdiction where the construction project is taking place to ensure compliance with local regulations and safety standards.

- Q: Can steel H-beams be used in industrial applications?

- Yes, industrial applications can utilize steel H-beams. H-beams, also recognized as I-beams or W-beams, possess a cross-section resembling the letter "H" and are utilized in industrial construction projects, including building construction, bridge construction, and infrastructure development. Steel H-beams offer numerous benefits that render them suitable for industrial applications. Primarily, they provide exceptional structural support and load-bearing capabilities, making them ideal for heavy-duty applications. H-beams possess a high strength-to-weight ratio, allowing them to endure substantial loads while remaining relatively lightweight. This strength is crucial in industrial environments where there is a need to support heavy machinery, equipment, or materials. Moreover, steel H-beams exhibit exceptional durability and resistance to various environmental factors. They possess a high resistance to corrosion, which is significant in industrial applications where exposure to moisture, chemicals, or harsh weather conditions is common. The durability of steel H-beams ensures their extended lifespan and minimal maintenance requirements, making them a cost-effective option for industrial projects. Furthermore, H-beams are versatile and can be fabricated to meet specific design requirements. They are available in various sizes, lengths, and thicknesses, enabling engineers and architects to select the appropriate beam dimensions for their industrial applications. This versatility permits the customization of H-beams to accommodate specific load-bearing capacities, spans, and structural requirements. In summary, steel H-beams are extensively utilized in industrial applications due to their outstanding structural support, high strength-to-weight ratio, durability, resistance to corrosion, and versatility. These characteristics make them an ideal choice for diverse construction projects, ensuring the safe and efficient operation of industrial facilities.

- Q: What are the durability considerations for steel H-beams?

- When considering the durability of steel H-beams, several factors need to be taken into account. Firstly, the quality and grade of the steel used in the construction of the H-beams play a significant role in determining their durability. Higher-grade steels, such as those with increased tensile strength and corrosion resistance, tend to have better longevity. Another crucial consideration is the protective coatings applied to the H-beams. Coatings like galvanization or epoxy can enhance the durability of the steel by providing a barrier against corrosion and other environmental factors. Regular maintenance and inspections of the protective coatings are necessary to ensure their effectiveness over time. Furthermore, the load-bearing capacity of the steel H-beams should be evaluated to determine their durability. Adequate design and engineering must be employed to ensure that the beams can withstand the expected loads and stresses without deformation or failure. Environmental conditions, such as exposure to moisture, extreme temperatures, or chemicals, can also impact the durability of steel H-beams. Proper precautions, including appropriate coatings, ventilation, and drainage systems, should be implemented to minimize the potential negative effects of these conditions. Lastly, the installation and connection methods used for steel H-beams can affect their durability. Proper welding, bolted connections, or other joining techniques should be employed to ensure that the beams are securely fastened together and can withstand the anticipated forces and movements without compromising their structural integrity. In conclusion, the durability of steel H-beams depends on factors such as the quality of the steel, protective coatings, load-bearing capacity, environmental conditions, and proper installation and connections. Considering these aspects and implementing necessary measures will help ensure the long-term durability of steel H-beams in various applications.

Send your message to us

Hot Rolled Steel I-Beam with good quality from china

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords