Jacketed Beer Bright Tank Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Description:

Processing: Storage Tank, cutting-rolling-welding-polishing-assembling-testing-warehousing

Condition: New

Place of Origin: Zhejiang, China (Mainland)

Brand Name: KUNBO

Model Number: bright tank, KB-006

Processing Types: Alcohol

Voltage: 380V, 50HZ

Certification: B&V; CE

Image:

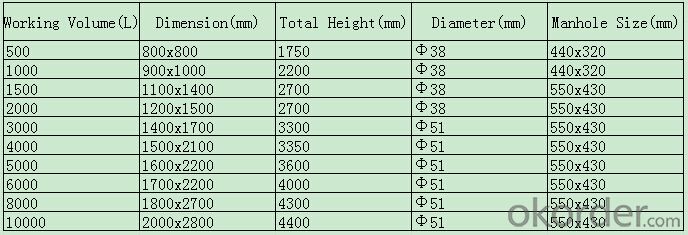

Specifications

1.manhole 2.CIP spraying ball 3.adjusting feet 4.sample valve 5.temperature gauge 6.pressure gauge 7.level gauge

Technical Data:

- Q: what is the difference between a hot water boiler and a steam boiler?

- about 100 degrees.

- Q: What is the full name of the CFB boiler?

- CFB boiler is circulating fluidized bed boiler.

- Q: there's alot of detail in the new molds i have which require different colors, does the dbl boiler method keep the candy melty longer? and wut should the consistency b when painting in 'features of the face' ?

- Double Boiler is the most effective method.

- Q: Hi,Please let me Know Operational Difference between 2-Pass and 3-Pass Steam Boilers, which one is more efficient.

- The operation of the two boilers is the same. As to boiler efficiency it is s matter of boiler design, surface area, air control and and extra devices such as air preheaters or feed water heaters.

- Q: I am in the market for a new oil-fired hot water boiling furnace for my home. Some installers have recommended Peerless brand and I wondered what type of experiences you may have had with this make. Also, I am taking suggestions for other makes. Thanks!

- peerless makes a good boiler. weil mclean gold is also another good one.

- Q: I'm looking at purchasing a steam generator from 1 of 2 manufacturers and one side says theirs is better because it does not modulate and the other says it is better because it does modulate.Thank you for any help.

- by modulation I expect they mean variable firing rate. Some boilers work on a low a high fire rate. The low is set to just below the minimum steam requirements when the pressure drops slightly the burner swings to high fire until the pressure recovers. A modulating burner continuously adjusts its flame to match the steam demand. A modulating boiler is better if you have a fairly steady steam demand but has trouble keeping up with widely varying loads.

- Q: I have a Vaillant boiler, I think it's a combi boiler. We moved into the house in January and since then we have had heating and hot water on demand, no problems. Suddenly this week the hot water seems to have been running out and the heating hasn't been coming on.I have looked at the boiler and a F22 fault is coming up, which apparently means dry fire .. whatever that means. I have bled all the radiators and there is no air in the system, however the pressure (bar) reading is bottomed out entirely. Does anyone have any ideas before I call a plumber?

- This Site Might Help You. RE: Vaillant Boiler, Code F22, water pressure? I have a Vaillant boiler, I think it's a combi boiler. We moved into the house in January and since then we have had heating and hot water on demand, no problems. Suddenly this week the hot water seems to have been running out and the heating hasn't been coming on. I have looked at the...

- Q: When the hot water tap is switched on, the boiler fires up for 5 seconds then cuts out for 5 seconds then fires up for 5 etc. etc. etc. Water too cold for a bath

- is there enough flow thru the boiler.?I have ferroli boiler and the recent really cold weather (water mains is about 4 degreesC) made us keep half closing the taps to get a hot bath if you go too far you either get the water so hot it trips the hi level cut out inside the boiler. Or not enough flow to operate the boiler itself. My cure was to fill the bath (taps on full but luke warm water) then do the final top up from the shower part of mixer tap which gives reduced flow but really hot without tripping boiler stat. I have already decided to change for better boiler as soon as can afford one buy a boiler from a cold place manufacturer they know about these things

- Q: A boiler with a steel bottom 15 mm thick rests on a hot stove; the area of the bottom of the boiler is 0.15 m^2. The water inside the boiler is at 100°C and 0.75 kg evaporates every minute.Calculate the temperature of the lower surface of the boiler, where it is in contact with the stove.

- It will be important to look up what value your textbook gives for the thermal conductivity of steel. I'm going to use 50 W/(m K), but I found different values in different places. The latent heat of evaporation for water seems to be more of an agreed value: 2260 kJ/kg The heat required to evaporate 0.75 kg per minute is 1695 kJ/minute = 28.25 kW The heat transferred through the bottom of the boiler is k A delta-T / d where k = 50 W/(m K) A = 0.15 m^2 d = 0.015 m and delta-T is to be calculated. 28,250 W = 50 W/(m K) times 10 m times delta-T delta-T = 56.5 K I guess the temperature of the lower surface of the boiler is 156.5 Celsius. Check my arith.

- Q: I am still young and don't really understand the market. Can you guys explain to me what happened in that movie?

- essentially, the boiler room is about a group of guys running a scam. what they do is buy penny stocks. these are stocks that don't trade often enough or don't have a lot of shares to trade or aren't very expensive. anyway, these guys buy shares of a company that's about to announce some news, and then they try to sell off their shares when their customers are buying say they bought company X for $1 - they tell their customers that company X is going to jump in price soon and convince them to buy. the minute their customers and more people start buying, they dump their shares for a good profit. because these shares don't often trade, when people start buying the price goes up. fabricating rumors about a small company and getting people to invest money into a stock like this is a quick and easy way to make money. unless you're the last person trying to sell left holding shares when nobody wants to buy it. by the way, this is illegal - which is why the Feds were after them. good con guys find people with money and have them invest small amounts that make good returns. then, when they have their customers' confidence, they convince them to make a big investment in another sure thing - which of course is that time they make a killing and their customer goes broke. hope this helps explain the movie a bit.

Send your message to us

Jacketed Beer Bright Tank Stainless Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 500 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords