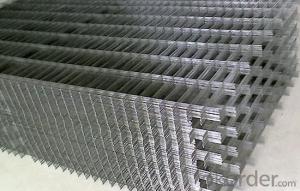

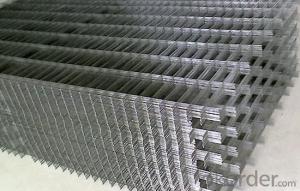

3D EPS Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meters m²

- Supply Capability:

- 3000 Sheets per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

3D EPS Wire Mesh Panel

PVC coating & powders coating

Material:Hot dipped galvanized wire

Material:Q235,Q195

ISO9001:2008 3D EPS Wire Mesh Panel

Technical Note of 3D EPS Wire Mesh Panel:

1,Standard roll length: 2.5m, 2.255m, 2.0m, 2.2m and others as requests

2.Width: 0.5m to 1.8m

3,Special sizes available at request

4,Packing: in waterproof paper in rolls. Customer’s packing available at request.

It can be used in

highway, railway, road, city transit, factory zone, industry zone, private grounds, public places

The surface treatment of welded wire fence include

electro galvanized, hot-dipped galvanized, PVC coated

Using high quality wire rod as raw material, the welded panel, after galvanized, powders primer, and powders top coating, it can resist the

corrosive and ultraviolet radiation very strongly.

- Q: Plastic pipe gas temperature 150 degrees, plastic pipe surface problems?

- The most widely used plastic pipe is plastic pipe. There are many kinds of plastic pipes, which are divided into two categories: thermoplastic pipes and thermosetting plastic pipes. It belongs to thermoplastic, including PVC pipe, polyethylene pipe, polypropylene pipe, POM pipe, super high molecular weight polyethylene pipe, etc. it belongs to thermosetting phenolic plastic pipe. The main advantages of plastic pipes are good corrosion resistance, light quality, convenient molding and easy processing. The disadvantages are low strength and poor heat resistance.

- Q: Is the plastic with high melting index good?

- It was established by the American Society for measurement standards (ASTM), a method used to identify plastic properties, according to the DuPont Co (DuPont).

- Q: Plastic raw materials, electroplating grade round face, electroplating grade, what is the concept?

- The so-called plastic raw material electroplating grade means that the particle of the plastic material is high in purity and high in polarity, and is easy to be evenly adhered to the metal particles before the plating.

- Q: How to use all kinds of plastic materials?

- AS (SAN) acrylic styrene transparent adhesiveAS is acrylonitrile (A), styrene (S) copolymer, weather resistant medium, not by the high humidity environment, ability, general oil, detergent and mild alcohol, poor fatigue resistance, not easy to crack due to stress, material quality high transparency, good liquidity in ABS.Suitable plastic products: tray, cups, cutlery, toothbrush, refrigerator cabinet, knob, lighting accessories, accessories, instrument mirror, packing box, stationery

- Q: How many kinds of raw materials are there for blowing plastic bottles?

- Plastic bottles are made of polyethylene or polypropylene and added a variety of organic solvents. Plastic bottles are widely used in polyester (PET), polyethylene (PE), polypropylene (PP) as raw material, add the corresponding organic solvent after high-temperature heating, the plastic mold by blow molding, extrusion blow or injection molding of plastic containers.

- Q: What is the essential difference between plastic raw materials and engineering plastics?

- Engineering plastics are a type of plastics, as well as general plastics.Like everyday things, what barrels, pots, plastic, etc?.

- Q: What are the specific differences between plastics and plastics?

- Plastic materials (LC plastic raw materials wholesale, high temperature resistant plastic material, PPS, LCP, PET, PA, PES plastic raw materials suppliers): the main ingredient is resin, is made of polymer resin as main ingredients into a variety of auxiliary material or adding agent, at a certain temperature, with plastic and motor can be under pressure molded into shape and maintain the same shape of material under certain conditions;

- Q: What type of raw material for plastic straw?

- The plastic is made of monomers as raw materials, polymer by polyaddition or polycondensation polymerization (macromolecules), commonly known as plastic resin (plastics) or (resin), can freely change the composition and form style, composed of synthetic resin and filler, plasticizer, stabilizer, lubricant, pigment and other additives.

- Q: What are the raw materials needed for making plastic bags?

- The bags made of two materials each have their own characteristics, and are chosen according to the purpose and performance of the products. Polyethylene is petrochemical products, prices vary according to crude oil and market conditions every day, at present LDPE (high pressure polyethylene) offer at 13500 yuan. HDPE (low pressure polyethylene) at 11000 yuan up and down.

- Q: What does MFI mean in PC material?

- MI (Melt, Flow, Index, or, MFI,), Melt, Flow, Rate (MFR), the full name of the melt flow index, or the melt flow index, refers to a plastic material processing when the flow performance of the value. It is a conventional method of identifying plastic properties.

1. Manufacturer Overview

| Location | Hebei, China |

| Year Established | 2005 |

| Annual Output Value | US$50 Million - US$100 Million |

| Main Markets | North America South America Eastern Europe Southeast Asia Oceania Mid East Eastern Asia Western Europe Northern Europe Southern Europe South Asia |

| Company Certifications | HACCP ;ISO 9001:2000 ;ISO 14001:2004 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | tianjin,huanghua,ningbo |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, French |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 10 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Average |

Send your message to us

3D EPS Wire Mesh Panel

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 Square Meters m²

- Supply Capability:

- 3000 Sheets per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords