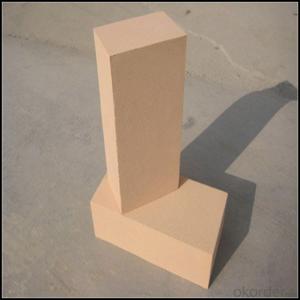

High Alumina Insulating Fire Bricks for High Temperature Working

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Advantages of high alumina brick

1 Excellent thermal stability

2 High refractoriness under load

3 Chemical stability and anti-corrision

4 Small high temperature creep rate

5 Excellent thermal shock resistance

Characteristices of high alumina brick

1.High intensity for pressure

2. Good thermal shock stability

3. Strong abrasion and corrosion resistance

4. High cold crushing strength

5. Excellent abrasion resistance at cold and hot conditions

Application

1. Furnaces of metallurgy industry, heat treatment furnace

2. Furnaces of chemical industry and construction industry.

3. Furnace of incineration of garbage, recirculating fluidized bed furnace

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in power plants?

- Yes, insulating fire bricks can be used in power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various applications in power plants, such as lining furnaces, boilers, and kilns. Insulating fire bricks help to conserve energy, improve efficiency, and maintain a stable temperature within power plant equipment.

- Q: What are the dimensions of insulating fire bricks?

- Insulating fire bricks are usually available in different dimensions, which vary depending on the manufacturer and specific usage. However, the most frequently used dimensions for insulating fire bricks are 9 inches by 4.5 inches by 2.5 inches (or 230mm by 114mm by 64mm). These dimensions are widely accepted and commonly employed in the industry. It is worth mentioning that distinct projects might necessitate diverse dimensions, and it is advisable to consult the manufacturer or supplier to determine the most suitable dimensions for your requirements.

- Q: Can insulating fire bricks be recycled or reused?

- Yes, insulating fire bricks can be recycled or reused. They can be crushed down and used as fillers in various construction materials or as a base material for roads. Additionally, they can be reclaimed and reused in various industrial processes that require heat insulation.

- Q: Are insulating fire bricks suitable for use in cement plants?

- Yes, insulating fire bricks are suitable for use in cement plants. Insulating fire bricks are made from lightweight refractory materials that are designed to resist high temperatures and thermal shock. These bricks have low thermal conductivity, which means they can effectively insulate against heat transfer. In cement plants, where high temperatures are generated during the production process, insulating fire bricks can be used in various applications. They can be used to line the kiln, where the raw materials are heated to extreme temperatures to produce cement clinker. The insulating properties of these bricks help to reduce heat loss and improve energy efficiency in the kiln. Additionally, insulating fire bricks can be used to line the preheater tower and other high-temperature areas in the cement plant. These bricks provide insulation and protection against the intense heat, helping to prolong the lifespan of the equipment and reduce maintenance costs. Furthermore, the lightweight nature of insulating fire bricks makes them easier to handle and install compared to traditional refractory bricks. This can save time and labor during the construction or repair of cement plant equipment. Overall, insulating fire bricks are a suitable choice for use in cement plants due to their high-temperature resistance, low thermal conductivity, and ease of installation. They can contribute to improved energy efficiency, equipment durability, and cost savings in cement plant operations.

- Q: Can insulating fire bricks be used in high-temperature kilns for pottery?

- Yes, insulating fire bricks can be used in high-temperature kilns for pottery. Insulating fire bricks are specifically designed to withstand high temperatures, typically up to 3000°F (1650°C). These bricks have low thermal conductivity, which means they can effectively retain heat and provide insulation in kilns. Using insulating fire bricks in high-temperature kilns can help maintain a consistent temperature throughout the firing process, ensuring that the pottery is properly heated and cooled. Additionally, these bricks are lightweight, which makes them easier to handle and install in kilns. Overall, insulating fire bricks are a suitable choice for high-temperature kilns used in pottery.

- Q: Can insulating fire bricks be used for insulation in aluminum smelters?

- Yes, insulating fire bricks can be used for insulation in aluminum smelters. Insulating fire bricks are made from special lightweight materials that have high insulating properties, making them ideal for applications that require high-temperature insulation. Aluminum smelters operate at extremely high temperatures, and insulating fire bricks can effectively withstand and retain the heat, preventing heat loss and improving energy efficiency. Additionally, these bricks are resistant to thermal shock, a common occurrence in smelting processes, which makes them highly suitable for use in aluminum smelters. Insulating fire bricks can also provide a protective barrier, reducing the risk of heat damage to the surrounding structures and equipment. Therefore, using insulating fire bricks for insulation in aluminum smelters can enhance thermal efficiency, reduce energy consumption, and ensure a safe and efficient smelting process.

- Q: Insulation brick should pay attention to external walls?

- Before the tile is adhered, the water spraying device is applied to spray the wet water on the adhered base layer so as not to flow better.

- Q: Can insulating fire bricks be used in the construction of steel rolling mills?

- Yes, insulating fire bricks can be used in the construction of steel rolling mills. Insulating fire bricks are designed to have excellent thermal insulation properties, which makes them ideal for applications that require high temperatures and heat containment. In steel rolling mills, where high temperatures are involved, insulating fire bricks can be used to line the walls of furnaces, ovens, and other heat-processing equipment. These bricks help to reduce heat loss, increase energy efficiency, and maintain a stable temperature environment, which is crucial in the steel rolling process. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for construction in steel rolling mills.

- Q: Can insulating fire bricks be used in chimney liners?

- Yes, insulating fire bricks can be used in chimney liners. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation properties. They are commonly used in applications such as kilns, furnaces, and fireplaces where heat retention is important. When used as chimney liners, insulating fire bricks help to protect the chimney walls from the extreme heat generated by the fire, while also minimizing heat loss. This can improve the efficiency of the chimney and reduce the risk of damage to the surrounding structure. However, it is important to consult with a professional chimney technician or engineer to ensure that the specific type of insulating fire brick being used is suitable for the intended application and meets all relevant safety standards and building codes.

- Q: Can insulating fire bricks be used in the construction of thermal insulation walls?

- Yes, insulating fire bricks can be used in the construction of thermal insulation walls. These bricks are designed to have low thermal conductivity, which helps to minimize heat transfer. They are widely used in applications where thermal insulation is required, including the construction of walls and other structures that need effective insulation against high temperatures.

Send your message to us

High Alumina Insulating Fire Bricks for High Temperature Working

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 500 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords