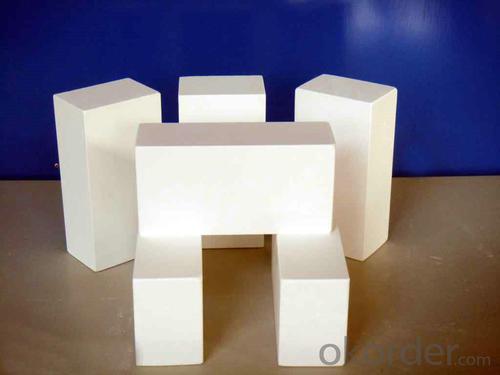

Insulating Fire Brick - Unshaped Refractory Fire Clay Bricks for Furnace Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Thermal Insulation Fire Clay Brick

Refractory brick is a block of refractory ceramic material used in lining furnaces, kilns, fireboxes, and fireplaces.

We provide high quality Refractory Fire Bricks that are used on wide range in the various industries like Cement, Glass and Steel. Refractory Fire Bricks are provided as per the quantity and specifications required by the customers. We provide an extensive range of Refractory Fire Bricks at reasonable prices that depend upon the quantity ordered.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Professional marketing team and after-sale service

Insulating Fire Brick main feature:

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: Can insulating fire bricks be used for outdoor applications?

- Insulating fire bricks can be used for outdoor applications, but it is important to consider their limitations and suitability for specific purposes. Insulating fire bricks are designed to provide excellent thermal insulation, making them ideal for applications where heat retention is crucial. They are commonly used in high-temperature environments such as kilns, furnaces, and fireplaces. However, when using insulating fire bricks outdoors, some factors need to be taken into account. Firstly, insulating fire bricks are not as durable or weather-resistant as regular bricks. They are more susceptible to damage from moisture, freezing temperatures, and exposure to the elements. Therefore, they may not be the best choice for applications that require long-term durability or frequent exposure to rain, snow, or extreme weather conditions. Additionally, insulating fire bricks have lower compressive strength compared to regular bricks, which means they may not be suitable for structural applications that require high load-bearing capacity. They are better suited for non-load-bearing applications such as insulation, lining, or cladding. In conclusion, while insulating fire bricks can be used for outdoor applications, it is important to carefully evaluate their limitations and choose them for the right purposes. It is recommended to consult with experts or suppliers to determine the suitability of insulating fire bricks for specific outdoor projects.

- Q: Can insulating fire bricks be used as insulation in walls and roofs?

- Insulation in walls and roofs can be achieved by utilizing insulating fire bricks. These bricks are constructed from lightweight materials that possess exceptional thermal insulation properties. Their thermal conductivity is low, allowing them to effectively minimize heat transfer through walls and roofs. Consequently, they are a fitting selection for enhancing energy efficiency and insulating buildings. Furthermore, insulating fire bricks are both long-lasting and fire-resistant, rendering them a secure choice for insulation. Nevertheless, it is crucial to acknowledge that these bricks are typically employed in high-temperature environments such as furnaces and kilns. Thus, they might not be the most economical or practical option for all wall and roof insulation requirements. In terms of cost, installation ease, and overall performance, other insulation materials specifically designed for building applications may be more appropriate.

- Q: Can insulating fire bricks be used in drying ovens?

- Yes, insulating fire bricks can be used in drying ovens. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in ovens where drying processes occur. They help to maintain a consistent and efficient heat distribution, ensuring effective drying of the materials inside the oven.

- Q: Do insulating fire bricks require any special anchors or supports for installation?

- Special anchors or supports are necessary for the installation of insulating fire bricks in certain applications. These bricks are lightweight and have low thermal conductivity, making them suitable for high-temperature environments like furnaces, kilns, and fireplaces. However, their lightweight nature can cause them to move or shift under certain conditions. To ensure the stability and integrity of the insulating fire bricks, it is important to use special anchors or supports during installation. These anchors or supports are typically made of metal, such as stainless steel, and are designed to securely hold the bricks in place. They prevent the bricks from shifting or falling out, especially when exposed to vibrations, thermal expansion/contraction, or other external forces. The specific type and design of the anchors or supports depend on the application and installation requirements. Common types include V anchors, U anchors, and L anchors, which can be embedded into the surrounding refractory material or attached to a structural frame. The anchors or supports should be spaced and installed correctly according to the manufacturer's guidelines to ensure sufficient support and stability of the insulating fire bricks. In conclusion, although insulating fire bricks offer excellent thermal insulation properties, they require special anchors or supports for installation to prevent movement or displacement. These anchors or supports are crucial for maintaining the structural integrity and longevity of the insulating fire brick system.

- Q: Are insulating fire bricks suitable for use in steel mills?

- Yes, insulating fire bricks are suitable for use in steel mills. Insulating fire bricks are made from lightweight materials that have high insulating properties, allowing them to withstand high temperatures and provide effective insulation. In steel mills, where extremely high temperatures are generated during the steelmaking process, insulating fire bricks are used to line furnaces, kilns, and other high-temperature applications. These bricks help to reduce heat loss, improve energy efficiency, and protect the steel mill equipment from excessive heat. Additionally, insulating fire bricks have good thermal shock resistance, which is essential in steel mills where rapid temperature changes occur. Overall, the use of insulating fire bricks in steel mills is a reliable and effective solution for maintaining high-temperature environments and optimizing the steelmaking process.

- Q: Can insulating fire bricks be used in the construction of ceramic fiber-lined kilns?

- Indeed, the utilization of insulating fire bricks is possible for the construction of ceramic fiber-lined kilns. These specialized bricks are purposely designed to deliver exceptional insulation, rendering them ideal for situations that prioritize heat retention. By combining them with ceramic fiber lining, insulating fire bricks contribute to enhanced energy efficiency and diminished heat dissipation within kilns. Moreover, their lightweight nature and ease of handling facilitate simpler installation and construction of the kiln. Ultimately, the incorporation of insulating fire bricks in the construction of ceramic fiber-lined kilns positively impacts the kiln's overall performance and efficiency.

- Q: Are insulating fire bricks resistant to high-pressure environments?

- Insulating fire bricks, despite their excellent thermal insulation properties and high temperature resistance, are not explicitly engineered to endure high-pressure surroundings. Their capacity to withstand pressure is restricted. Generally, insulating fire bricks are employed in low-pressure scenarios where their insulation properties take precedence over their ability to endure pressure. If there is apprehension about a high-pressure environment, it is advisable to utilize alternative refractory bricks that are explicitly designed for such conditions, such as dense fire bricks or high-alumina bricks. These alternatives provide superior strength and pressure resistance.

- Q: Can insulating fire bricks be used in power plants?

- Yes, insulating fire bricks can be used in power plants. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for various applications in power plants, such as lining furnaces, boilers, and kilns. Insulating fire bricks help to conserve energy, improve efficiency, and maintain a stable temperature within power plant equipment.

- Q: Can insulating fire bricks be used in the construction of regenerators?

- Yes, insulating fire bricks can be used in the construction of regenerators. These bricks are designed to have low thermal conductivity, which makes them suitable for applications that require heat insulation. Regenerators, which are used in various industries like glass manufacturing and metal refining, require materials that can withstand high temperatures and efficiently store and release heat. Insulating fire bricks can fulfill these requirements, making them a suitable choice for regenerator construction.

- Q: Can insulating fire bricks be used in the construction of boilers for power plants?

- Insulating fire bricks have the capability to be utilized in the construction of boilers for power plants. These bricks are specially designed to possess a low thermal conductivity, enabling them to retain heat and prevent the loss of energy. This particular characteristic makes them well-suited for high-temperature applications like power plant boilers, where efficient heat transfer is vital for the production of steam and the generation of electricity. Furthermore, insulating fire bricks are lightweight and exhibit good resistance to thermal shocks, making them appropriate for the demanding conditions typically encountered in power plants. On the whole, incorporating insulating fire bricks into the construction of boilers can enhance energy efficiency and diminish heat loss, resulting in improved operational performance and cost savings for power plants.

Send your message to us

Insulating Fire Brick - Unshaped Refractory Fire Clay Bricks for Furnace Use

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords