Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Light Brick Thermal Insulating Fire Brick

High alumina insulating fire brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

This series of High Alumina Insulating Fire Brick are made of selected high alumina bauxite, kaolin caly, hollow microsphere as the mian material.By shaping at high pressure and sintering at high temperature.

Product Applications:

High alumina insulating fire brick are ideal for use in the below applications

Building materials for blast furnace

Building materials for hot-blast stove

Building materials for coke oven

Building materials for steel making furnace

For construction material in steel industry

For ladle

Product Advantages:

CNBM has success in its High alumina insulating fire brick due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Excellent thermal stability

High refractoriness under load

Chemical stability and anti-corrision

Small high temperature creep rate

Excellent thermal shock resistance

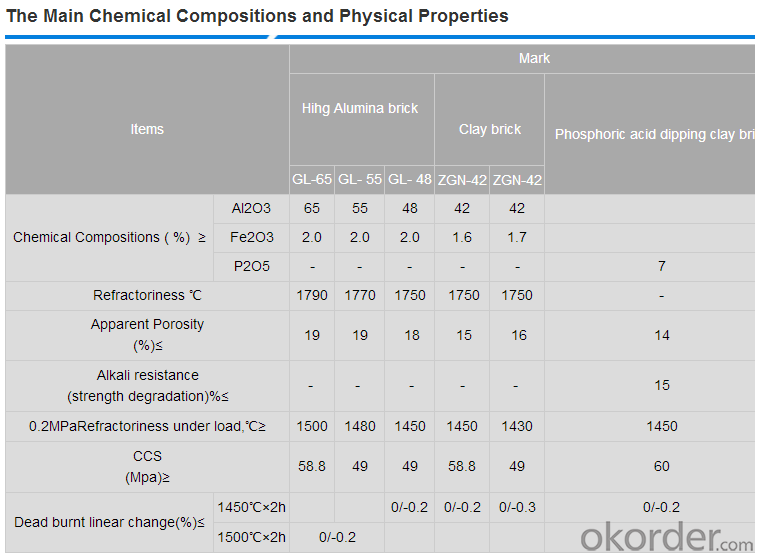

Product Specifications:

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

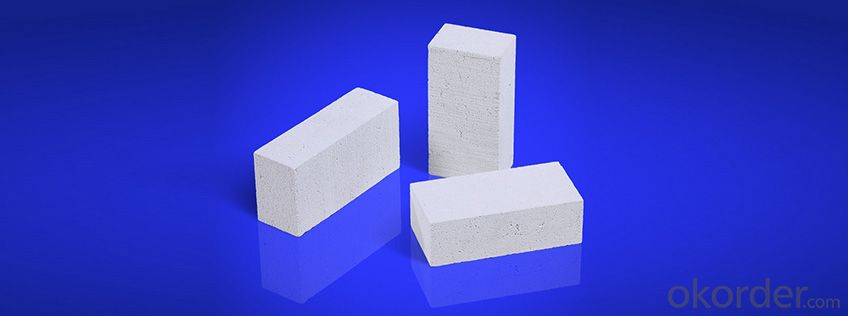

Product Picture

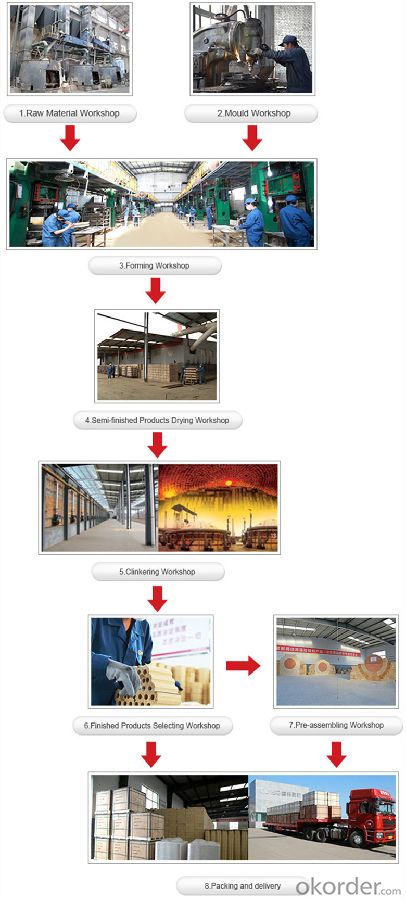

Produce Processing

- Q: Are insulating fire bricks suitable for use in chimneys and fireplaces?

- Yes, insulating fire bricks are suitable for use in chimneys and fireplaces. They have excellent thermal insulation properties, which helps to retain heat and prevent the transfer of excessive heat to the surrounding structure. This makes them a safe and efficient choice for lining chimneys and fireplaces, as they can withstand high temperatures and reduce the risk of heat damage.

- Q: Can insulating fire bricks be used in the construction of thermal insulation floors?

- Yes, insulating fire bricks can be used in the construction of thermal insulation floors. Insulating fire bricks are specially designed to have low thermal conductivity, which means they can effectively prevent the transfer of heat. This makes them an excellent choice for thermal insulation applications, including floors. By using insulating fire bricks in the construction of thermal insulation floors, the heat loss from the floor can be significantly reduced, leading to improved energy efficiency and cost savings. Additionally, insulating fire bricks are lightweight and easy to install, making them a practical choice for construction projects. Overall, insulating fire bricks are a suitable and effective option for incorporating thermal insulation into floors.

- Q: Can insulating fire bricks be used in high-temperature filters?

- Yes, insulating fire bricks can be used in high-temperature filters. These bricks are designed to withstand extreme temperatures and provide excellent insulation. They can effectively trap and filter out impurities in high-temperature environments, making them suitable for use in high-temperature filters.

- Q: Are insulating fire bricks resistant to moisture penetration?

- Insulating fire bricks exhibit resistance to moisture penetration, as they are designed with low porosity, resulting in a minimal water absorption rate. This attribute grants them formidable protection against moisture infiltration. These bricks find frequent application in environments characterized by elevated temperatures and harsh conditions, including kilns, furnaces, and fireplaces. Their durability and effectiveness in such settings are guaranteed by their ability to ward off moisture penetration.

- Q: Can insulating fire bricks be used in chimneys and flues?

- Yes, insulating fire bricks can be used in chimneys and flues. These bricks are designed to withstand high temperatures and provide insulation, making them suitable for use in areas where heat needs to be contained or controlled, such as chimneys and flues.

- Q: How do insulating fire bricks affect the overall sustainability of a structure?

- Insulating fire bricks play a crucial role in enhancing the overall sustainability of a structure. These bricks are designed to have low thermal conductivity, which helps in minimizing heat loss from the building. By providing effective insulation, they contribute to energy efficiency by reducing the need for excessive heating or cooling. This, in turn, leads to lower energy consumption and reduced carbon emissions, making the structure more environmentally friendly. Furthermore, insulating fire bricks have excellent durability, enabling them to withstand high temperatures and extreme conditions, resulting in longer-lasting structures that require fewer repairs and replacements. Overall, insulating fire bricks enhance the sustainability of a structure by improving energy efficiency and durability, leading to reduced environmental impact and long-term cost savings.

- Q: Can insulating fire bricks be used in the construction of BBQ pits?

- Indeed, the utilization of insulating fire bricks is feasible for the construction of BBQ pits. These bricks are specifically engineered to endure extreme temperatures and possess exceptional heat resistance attributes, rendering them perfectly suited for BBQ pit applications. By incorporating these bricks, heat is effectively captured and evenly dispersed, leading to improved cooking efficiency and a more enjoyable BBQ experience. Moreover, the inclusion of insulating fire bricks aids in minimizing heat dissipation, guaranteeing that the BBQ pit retains and sustains heat for an extended duration. All in all, the integration of insulating fire bricks significantly enhances the overall performance and longevity of the BBQ pit.

- Q: Are insulating fire bricks resistant to moisture or water damage?

- Yes, insulating fire bricks are resistant to moisture or water damage. They are designed to withstand high temperatures and do not absorb water, making them a suitable choice for applications where moisture or water exposure is a concern.

- Q: Can insulating fire bricks be custom-made?

- Yes, insulating fire bricks can be custom-made. Insulating fire bricks are typically made from lightweight materials such as vermiculite, perlite, or refractory fibers, which can be easily molded into various shapes and sizes. This flexibility allows manufacturers to create custom-made insulating fire bricks to meet specific requirements and applications. Customization options may include variations in dimensions, thermal conductivity, compressive strength, and density. By tailoring the composition and design of insulating fire bricks, they can be optimized for specific temperature ranges, insulation requirements, and environmental conditions. Therefore, customers can work with manufacturers to develop custom solutions that best suit their unique needs.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Yes, it is possible to cut insulating fire bricks to fit custom shapes. These bricks can be easily cut using a saw or other cutting tools to achieve the desired shape and size for specific applications.

Send your message to us

Insulating Fire Brick - Refractory Thermal Insulating Light Brick

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords