Insulating Fire Brick - Refractory Mullite Insulating Fire Brick for Heating Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of High Purity Corundum Brick:

High purity corundum brick SiO2<0.2%, Al2O3>99%, used in petrochemical industry furnace, gasification furnace and large fertilizer equipment, and more than 1600° C super high temperature furnace, liner of furnace. Long life and reliable in quality. We can make different kinds of shape products according the customer's drawing.

2. Main features of High Purity Corundum Brick

1. High compression strength.

2. Top high-temperature capability.

3. Excellent thermal stability.

4. Low thermal conductivity.

5. Powerful penetrating-proof capability.

6. Good erosion-resistance.

7. Long service life.

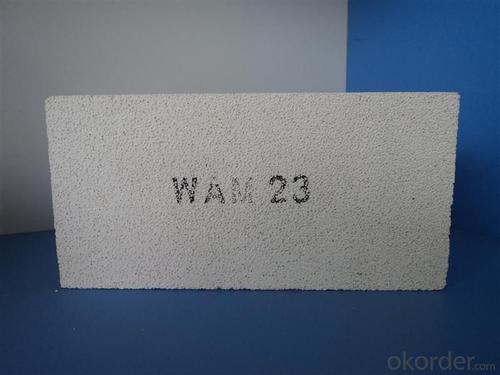

3. High Purity Corundum Brick Images:

4. Applications of High Purity Corundum Brick:

Mullite lightweight brick plant can be in direct contact with the flame,this insulating brick can be used as linings or as thermal preservation layers in various industrial furnaces and kilns in metallurgical industry, ceramic industry, chemical industry, machinery industry.

such as blast furnace, hot blast stoves ,electric arc furnace, cement kiln,melting furnace, ignition furnace, flue, refining equipment, heating equipment and piping, regeneration device, gas furnace, soaking furnace, annealing furnace, heat reaction chamber and other thermal industrial equipment.

- Q: Can insulating fire bricks be used as a lining material for boilers?

- Insulating fire bricks have the capability to serve as a lining material for boilers. They are composed of lightweight refractory substances that possess exceptional insulating properties. The bricks are specifically constructed to withstand elevated temperatures, thus rendering them appropriate for usage in boilers, where temperatures can soar to several hundred degrees Celsius. By virtue of their insulating properties, these bricks aid in minimizing heat loss, thereby enhancing the energy efficiency of the boiler. Moreover, they exhibit resistance against thermal shock, a vital attribute for enduring the rapid fluctuations in temperature that transpire within boilers. Ultimately, owing to their remarkable insulating properties and capacity to endure high temperatures, insulating fire bricks emerge as a suitable alternative for lining boilers.

- Q: Can insulating fire bricks be used in the construction of glassware production furnaces?

- Yes, insulating fire bricks can be used in the construction of glassware production furnaces. These bricks have excellent thermal insulation properties and can withstand high temperatures, making them ideal for creating a well-insulated and efficient furnace for glass production.

- Q: Are insulating fire bricks resistant to nitrogen oxides?

- Insulating fire bricks are known for their excellent thermal insulation properties and are commonly used in high-temperature applications such as furnaces, kilns, and industrial boilers. While they are highly resistant to heat and can withstand extreme temperatures, their resistance to nitrogen oxides (NOx) may vary depending on the specific composition and manufacturing process of the bricks. Nitrogen oxides are a group of harmful gases that are produced during combustion processes, particularly at high temperatures. These gases can have detrimental effects on human health and the environment. Although insulating fire bricks have a high melting point and can withstand intense heat, they may not provide sufficient resistance to nitrogen oxides on their own. To enhance the resistance of insulating fire bricks to nitrogen oxides, additional measures and coatings may be required. These could include the use of specialized refractory coatings or the incorporation of specific additives during the manufacturing process to create a more chemically resistant brick. It is important to note that the resistance of insulating fire bricks to nitrogen oxides may also depend on the specific application and operating conditions. Different types of nitrogen oxides, such as nitrogen dioxide (NO2) or nitric oxide (NO), may have different effects on the bricks. Therefore, it is recommended to consult the manufacturer or a specialist in refractory materials to determine the suitability of insulating fire bricks in a specific environment where the presence of nitrogen oxides is a concern.

- Q: Are insulating fire bricks resistant to thermal shock cracking?

- Insulating fire bricks exhibit resistance against thermal shock cracking. These bricks are engineered to endure elevated temperatures and sudden temperature variations without experiencing cracks. With their low thermal conductivity, they efficiently capture and retain heat while remaining unharmed by thermal shock. Consequently, insulating fire bricks find frequent application in contexts where thermal shock poses a potential hazard, such as furnaces, kilns, and other environments with high temperatures. Their dependable resistance to thermal shock cracking renders them a trustworthy selection for such applications.

- Q: Are insulating fire bricks suitable for use in residential fireplaces?

- Yes, insulating fire bricks are suitable for use in residential fireplaces. They are designed to withstand high temperatures and provide insulation, making them an ideal choice for ensuring the safety and efficiency of a residential fireplace.

- Q: How do insulating fire bricks affect the overall thermal efficiency of a building?

- Insulating fire bricks can greatly enhance the thermal efficiency of a building by providing excellent insulation properties. These bricks have low thermal conductivity, which means they can effectively reduce heat transfer through the walls and floors. By using insulating fire bricks, the building can retain more heat during cold weather and prevent heat from entering during hot weather, resulting in reduced energy consumption for heating and cooling.

- Q: Can insulating fire bricks be used in wood-fired kilns?

- Yes, insulating fire bricks can be used in wood-fired kilns. Insulating fire bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for use in wood-fired kilns where temperatures can reach extreme levels.

- Q: Do insulating fire bricks emit any toxic fumes when heated?

- Insulating fire bricks, also referred to as refractory bricks, have been designed to endure high temperatures and are commonly utilized in furnaces and kilns. These bricks are constructed from materials with low thermal conductivity, thus impeding the transfer of heat easily. When subjected to heat, insulating fire bricks do not discharge any toxic fumes. This is due to their composition, typically consisting of non-toxic substances like clay or silica. These materials possess chemical stability and do not release any harmful gases or substances when exposed to elevated temperatures. It is significant to acknowledge that although insulating fire bricks themselves do not emit toxic fumes, the substances undergoing heating inside the furnace or kiln may generate fumes or gases that could pose health hazards. Therefore, it is vital to adequately ventilate the area and adhere to safety guidelines when working with any materials that could release toxic fumes during the heating process. In conclusion, insulating fire bricks, made from non-toxic materials, do not emit toxic fumes when heated. Nevertheless, it is essential to ensure proper ventilation and follow safety precautions when working with materials that may emit hazardous fumes.

- Q: If there is a main component of cenosphere light insulating brick.

- Light heat insulation brick with cenosphere composition, material properties will be more high, especially the main properties of thermal conductivity

- Q: What is the recommended method for installing insulating fire bricks?

- The recommended method for installing insulating fire bricks involves several steps to ensure proper insulation and structural integrity. Here is a step-by-step guide: 1. Prepare the surface: Make sure the surface where the insulating fire bricks will be installed is clean and free from debris. Remove any loose or damaged bricks from the area. 2. Measure and plan: Measure the area where the bricks will be installed and plan the layout accordingly. Take into consideration any openings or corners that may require special cutting or shaping of the bricks. 3. Cut the bricks: Use a diamond blade saw or a masonry saw to cut the insulating fire bricks to the desired size and shape. Wear appropriate protective gear, such as safety goggles and a dust mask, when cutting the bricks. 4. Apply adhesive: Apply a thin layer of refractory adhesive or mortar to the surface where the first brick will be placed. Spread the adhesive evenly using a trowel or a notched trowel. 5. Place the bricks: Carefully place the first brick onto the adhesive, pressing it firmly into place. Ensure that it is level and aligned with the adjacent bricks. Repeat this step for the remaining bricks, leaving a small gap between each brick for expansion. 6. Fill the gaps: Fill the gaps between the bricks with refractory mortar, using a trowel or a grout bag. Press the mortar firmly into the gaps to ensure a tight seal. 7. Allow for curing: Let the adhesive and mortar cure for the recommended time, usually 24 to 48 hours. This will ensure that the bricks are securely bonded and ready for use. 8. Test and insulate: After the curing period, test the installation by gently tapping the bricks to check for stability. Once confirmed, you can proceed with insulating the surrounding area if required, following the manufacturer's instructions. Remember to always follow the specific instructions provided by the manufacturer of the insulating fire bricks and any adhesive or mortar being used. Additionally, it is advisable to consult with a professional or experienced installer if you are unsure about any step of the installation process.

Send your message to us

Insulating Fire Brick - Refractory Mullite Insulating Fire Brick for Heating Furnace

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords