Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

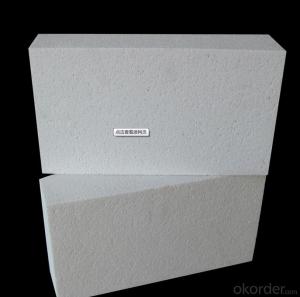

mullite insulation brick

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

Light weight mullite insulation furnace bricks refractory for sale

Advantage

1. Low thermal conductivity

2.High hot compressive strength

3.Perfect Energy saving

Refractory GJM Mullite Insulation Brick B-6

Description:

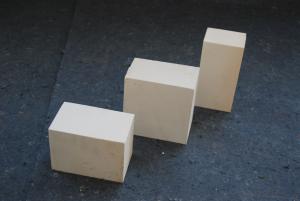

Lightweight mullite kiln bricks refractory for sale are made from good quality and superpure raw materials, with strictly classified fillings according to their grades. These fillings can form a uniform pore structure after burnt during the process of manufacture. Each grade of products has unique design to meet different thermal, physical and chomical demands.

Application:Refractory GJM Mullite Insulation Brick B-6

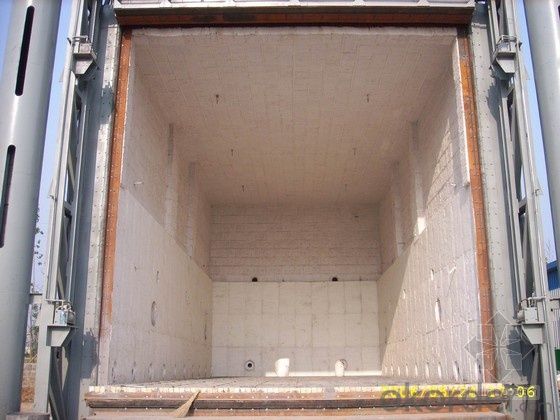

Mullite insulation furnace bricks refractory material can be used in linings or heat-insulating materials of the industries, such as, ethylene pyrolysis furnaces, tubular furnaces, reforming furnaces of synthetic ammonia, gas generators and high-temperature shullte kilns, etcRefractory GJM Mullite Insulation Brick B-6

Mullite Insulation furnace refractory material can be used as working lining, where contact with flames directly. This kind of brick can save the kiln energy very muchRefractory GJM Mullite Insulation Brick B-6

- Q: Are insulating fire bricks resistant to nitric acid?

- Yes, insulating fire bricks are generally resistant to nitric acid due to their high refractory properties and chemical stability.

- Q: Are insulating fire bricks resistant to insect infestation?

- Insulating fire bricks do not possess specific resistance against insect infestation. They are primarily utilized for their thermal insulation properties in applications involving high temperatures, such as kilns, furnaces, and fireplaces. Although they are generally not prone to insect damage, they are not entirely impervious to it either. Insects can still infiltrate the bricks if they discover small cracks or openings in the material. Nevertheless, insulating fire bricks are typically dense and compact, thereby making it challenging for insects to burrow or establish nests within them. It is always advisable to employ preventive measures for managing and eliminating potential insect infestations in any construction material, including insulating fire bricks, to ensure their durability and effectiveness.

- Q: Is it possible to paint or coat insulating fire bricks?

- Indeed, it is feasible to apply paint or coat insulating fire bricks. Nevertheless, it is imperative to utilize a type of paint or coating that can endure elevated temperatures, given that insulating fire bricks are intended for usage in exceedingly hot surroundings. Ordinary paint or coatings may not be appropriate since they can combust or deteriorate under high temperatures. It is advisable to employ specialized high temperature paint or coatings that have been specifically formulated to withstand the intense heat of insulating fire bricks. Typically, these types of paint or coatings possess a resistance to high temperatures of several hundred degrees Celsius or greater. Moreover, it is crucial to adequately clean and prepare the surface of the bricks prior to applying any paint or coating to ensure optimal adhesion and durability.

- Q: Do insulating fire bricks have good insulation performance at high temperatures?

- Yes, insulating fire bricks have excellent insulation performance at high temperatures. These bricks are designed to withstand extreme heat and provide effective insulation, making them ideal for applications such as kilns, furnaces, and other high-temperature environments.

- Q: Are insulating fire bricks suitable for use in the construction of incinerators?

- Yes, insulating fire bricks are suitable for use in the construction of incinerators. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties. Incinerators operate at extremely high temperatures, often exceeding 1000 degrees Celsius, and require materials that can withstand these intense conditions without cracking or deteriorating. Insulating fire bricks are made from lightweight refractory materials, such as ceramic fibers or lightweight aggregates, which have low thermal conductivity. This means that they are able to effectively insulate the incinerator, preventing heat from escaping and ensuring maximum energy efficiency. The insulation properties of these bricks also help to maintain a consistent temperature inside the incinerator, which is crucial for proper combustion and waste disposal. Furthermore, insulating fire bricks have excellent resistance to thermal shock, allowing them to withstand repeated heating and cooling cycles without damage. This is crucial in incinerators, where the temperature can fluctuate rapidly during the burning process. The bricks' ability to withstand thermal shock ensures their durability and longevity in this high-temperature environment. In addition to their insulation and thermal shock resistance, insulating fire bricks also offer other benefits for incinerator construction. They are lightweight, making them easier to handle and transport during the construction process. They can also be easily cut or shaped to fit specific designs or requirements, allowing for flexibility in the construction of incinerators. Overall, insulating fire bricks are an ideal choice for the construction of incinerators due to their high-temperature resistance, insulation properties, thermal shock resistance, durability, and ease of use. They provide a reliable and efficient solution for containing and maintaining the intense heat generated in incinerators, ensuring safe and effective waste disposal.

- Q: Can insulating fire bricks be used in the construction of hot air generators?

- Yes, insulating fire bricks can be used in the construction of hot air generators. Insulating fire bricks are designed to withstand high temperatures and provide excellent thermal insulation. This makes them suitable for use in hot air generators, which require insulation to maintain high temperatures and prevent heat loss. Insulating fire bricks help to increase the efficiency and performance of hot air generators by reducing heat transfer to the surroundings. Additionally, these bricks are lightweight, easy to install, and durable, making them a popular choice for various industrial applications including the construction of hot air generators.

- Q: Can insulating fire bricks be used for both residential and commercial purposes?

- Insulating fire bricks have the capability to serve both residential and commercial purposes. Their design is specifically intended to offer superior insulation and thermal protection, which makes them highly suitable for various applications. In residential environments, these bricks can be utilized to insulate fireplaces, wood-burning stoves, and even pizza ovens, among other possibilities. In commercial contexts, they are widely employed for kilns, furnaces, boilers, and industrial ovens. The widespread applicability of insulating fire bricks contributes to their popularity as a preferred option for projects that demand efficient thermal insulation, regardless of whether they are residential or commercial in nature.

- Q: Can insulating fire bricks be used in the construction of incineration kilns?

- Indeed, incineration kilns can utilize insulating fire bricks for their construction. These bricks are specifically designed to possess exceptional thermal insulation properties, rendering them highly suitable for scenarios involving high temperatures, such as incineration kilns. With their ability to withstand extreme temperatures, these bricks provide insulation that minimizes heat loss, thereby enhancing energy efficiency and reducing fuel consumption. Moreover, insulating fire bricks are lightweight, easy to handle, and can be readily molded and installed in different configurations, making them an ideal choice for constructing the intricate geometries commonly found in incineration kilns. By employing insulating fire bricks in the construction of incineration kilns, one can bolster their thermal performance, enhance their longevity, and contribute to more streamlined and effective waste management processes.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Yes, insulating fire bricks are resistant to carbon monoxide.

- Q: How thick are insulating fire bricks?

- Insulating fire bricks typically have a thickness ranging from 2.5 to 4 inches (6.35 to 10.16 cm). The specific thickness depends on the manufacturer and the intended application of the bricks. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns, furnaces, and other high-temperature environments.

Send your message to us

Insulating Fire Brick - Refractory GJM Mullite Insulation Brick B-6

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords