Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Information of Insulating Fire Brick GJM23

Insulating fire bricks GJM23 are made from high purity alumina and low iron content raw materials. The insulating fire bricks are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1260℃(2300℉). A variety of type could be done according to customer’s request.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM23,we choose the casting methord.The casting insulating fire bricks offering the lowest density, the lowest thermal conductivity for the application above 1000℃.

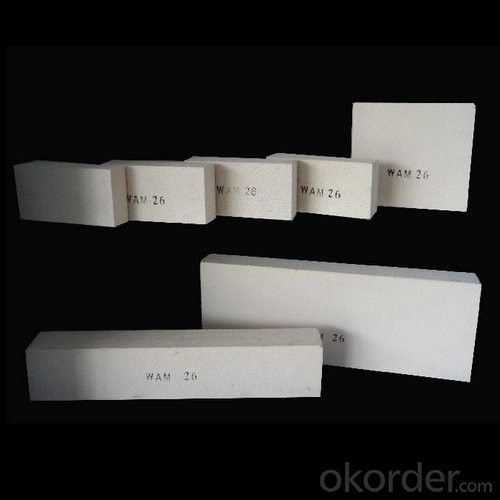

General Information of Insulating Fire Brick GJM26

Insulating fire brick GJM26 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM23 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM26,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM28

Insulating fire brick GJM28 are produced by high purity alumina and low iron raw materials. A viariety of shapes are available.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM28,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

General Information of Insulating Fire Brick GJM30

Insulating fire brick GJM30 are produced by mixing, casting or extruding, drying, sintering and grinding. Our insulating fire bricks GJM30 temperature is 1430℃(2600℉). We could supply a wide range of shapes.

To make our firebricks more energy and cost effective, we have different manufacturing methods for our insulating fire bricks casting and extruding method.

For insulating fire bricks GJM30,we choose the extruding method. Extruding insulating fire bricks have better strength and offering great performance in load bearing applications and in conditions where abrasion from mechanical abuse or flow of hot gases.

Typical Application of Insulating Fire Brick

Typical applications of magnesia bricks include ferroalloy furnace, metal mixer, Non-metallurgy industry furnace, high temperature kiln, calcined lime furnace, regenerator in glass furnace.

Technical Data of Insulating Fire Brick

| JM23 | JM26 | JM28 | JM30 | JM32 | ||||

| Physical Properties: | ||||||||

| Classifiction Temperature | ℃ | 1260.0 | 1430.0 | 1500.0 | 1600.0 | 1650 | ||

| Density | Kg/m3 | 550.0 | 850.0 | 900.0 | 1000.0 | 1100 | ||

| Cold Crushing Strength | Mpa | 1.2 | 2.0 | 2.5 | 2.8 | 3.5 | ||

| Reheating Linear Change(24hrs) | ||||||||

| 1230℃ | % | 0.4 | ||||||

| 1300℃ | ||||||||

| 1400℃ | % | 0.5 | ||||||

| 1510℃ | % | 0.6 | ||||||

| 1600℃ | % | 0.7 | ||||||

| 1650℃ | % | 0.8 | ||||||

| Hot Load Strength Deform(90 minutes) | ||||||||

| 1100℃ at 0.034 Mpa(5psi) | % | 0.1 | ||||||

| 1260℃ at 0.069 Mpa(10psi) | % | 0.2 | ||||||

| 1320℃ at 0.069 Mpa(10psi) | % | 0.3 | ||||||

| 1370℃ at 0.069 Mpa(10psi) | % | 0.2 | 0.1 | |||||

| Thermal Conductivity | ||||||||

| 400℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.32 | ||

| 600℃ | W/m.k | 0.2 | 0.3 | 0.3 | 0.3 | 0.35 | ||

| 800℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.38 | ||

| 1000℃ | W/m.k | 0.2 | 0.3 | 0.4 | 0.4 | 0.42 | ||

| 1200℃ | W/m.k | 0.4 | 0.4 | 0.4 | 0.44 | |||

| 1400℃ | W/m.k | |||||||

| Specific Heat | KJ/Kg.K | 1.1 | 1.1 | 1.1 | 1.1 | 1.10 | ||

| Chemical Analysis: | ||||||||

| Al2O3 | % | 47.0 | 50.0 | 60.0 | 70.0 | 75.0 | ||

| SiO2 | % | 44.4 | 47.1 | 38.2 | 28.3 | 23.2 | ||

| Fe2O3 | % | 0.9 | 0.7 | 0.6 | 0.5 | 0.5 | ||

| TiO2 | % | 1.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| CaO | % | 5.2 | 0.1 | 0.1 | 0.1 | 0.1 | ||

| MgO | % | 0.3 | 0.2 | 0.1 | 0.1 | 0.1 | ||

| Na2O+K2O | % | 1.1 | 1.7 | 0.8 | 0.7 | 0.6 | ||

Photo of Insulating Fire Brick

- Q: Can insulating fire bricks be used in the construction of pizza ovens?

- Indeed, it is possible to utilize insulating fire bricks during the construction of pizza ovens. With their ability to endure extreme temperatures and offer exceptional insulation, these bricks become an excellent choice for pizza ovens. They aid in the efficient preservation of heat, thus leading to a more uniform and steady cooking temperature. Additionally, due to their low thermal conductivity, insulating fire bricks effectively prevent heat dissipation, ensuring that the pizza oven remains hot for extended durations, thereby enhancing energy efficiency. All in all, incorporating insulating fire bricks into the pizza oven construction process can result in enhanced heat retention, improved cooking performance, and a more energy-efficient operation.

- Q: Are insulating fire bricks eco-friendly?

- Insulating fire bricks can be considered eco-friendly to some extent. These bricks are typically made from natural materials such as clay, shale, and other fire-resistant minerals, which are abundant and readily available. The production process involves firing the bricks at high temperatures, which can be energy-intensive, but modern manufacturing techniques have reduced the environmental impact by using more efficient kilns and recycled materials. Moreover, insulating fire bricks have a long lifespan and can withstand high temperatures, which means they require less frequent replacement compared to other types of bricks. This leads to a reduction in waste generation and resource consumption over time. Additionally, these bricks have excellent thermal insulation properties, which can help reduce energy consumption in various applications. By minimizing heat loss, insulating fire bricks can contribute to energy efficiency and lower carbon emissions in buildings and industrial processes. However, it is important to note that the eco-friendliness of insulating fire bricks also depends on their proper disposal at the end of their lifespan. If they are not recycled or disposed of properly, they can contribute to landfill waste and potential environmental pollution. In conclusion, while insulating fire bricks have certain eco-friendly attributes such as being made from natural materials and their energy-saving properties, their overall environmental impact also relies on responsible manufacturing, use, and disposal practices.

- Q: Are insulating fire bricks eco-friendly?

- Yes, insulating fire bricks can be considered eco-friendly. They are typically made from natural and sustainable materials such as clay and shale, which are readily available and do not deplete natural resources. Additionally, their high insulation properties help reduce energy consumption, making them an environmentally responsible choice.

- Q: Are insulating fire bricks suitable for use in incinerators?

- Yes, insulating fire bricks are suitable for use in incinerators. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation properties, making them ideal for use in incinerators. They have a high resistance to thermal shock and can retain their structural integrity even when exposed to extreme heat conditions. Additionally, insulating fire bricks have low thermal conductivity, which helps in reducing heat loss and improving the overall energy efficiency of the incinerator. Their ability to withstand high temperatures and provide effective insulation makes them a reliable choice for use in incinerators.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Yes, insulating fire bricks are highly resistant to moisture absorption. They are designed to have low porosity and are made from materials that do not readily absorb water. This makes them ideal for applications where moisture resistance is crucial, such as in kilns, furnaces, and other high-temperature environments.

- Q: Can insulating fire bricks be used in space heating applications?

- Yes, insulating fire bricks can be used in space heating applications. Insulating fire bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in heating systems where retaining heat is important. They can help increase the efficiency of space heating applications by reducing heat loss and ensuring more effective heat transfer.

- Q: Do insulating fire bricks require a specific curing or drying process before use?

- Yes, insulating fire bricks typically require a specific curing or drying process before use. This involves gradually heating the bricks to remove any moisture or volatile materials present, which helps to prevent cracking or damage during subsequent use. The exact curing or drying process may vary depending on the specific type and manufacturer of the insulating fire bricks.

- Q: Are insulating fire bricks resistant to carbon monoxide?

- Indeed, insulating fire bricks demonstrate a remarkable resistance to carbon monoxide. Tailored for enduring extreme temperatures, these bricks find common application in environments where they are likely to encounter both intense heat and corrosive agents, including carbon monoxide. The insulating nature of these bricks bestows upon them an exceptional ability to impede heat transfer, ensuring their structural integrity remains intact even in the presence of carbon monoxide and other combustible gases. This resistance to carbon monoxide renders insulating fire bricks a stellar choice for various settings like furnaces, kilns, and other high-temperature surroundings where the potential for carbon monoxide exposure looms.

- Q: Is it possible to cut insulating fire bricks to fit custom shapes?

- Yes, it is possible to cut insulating fire bricks to fit custom shapes. These bricks can be easily cut using a saw or other cutting tools to achieve the desired shape and size for specific applications.

- Q: Do insulating fire bricks require any maintenance?

- Yes, insulating fire bricks typically require minimal maintenance. They are designed to be durable and withstand high temperatures, so they generally do not need any special care or regular maintenance. However, it is important to inspect them periodically for any signs of damage or wear and tear, and if any issues are identified, they should be repaired or replaced to ensure their effective insulation properties.

Send your message to us

Insulating Fire Brick - Insulation Brick, Insulating Brick, GJM23, GJM26, GJM28, GJM30, GJM32

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords