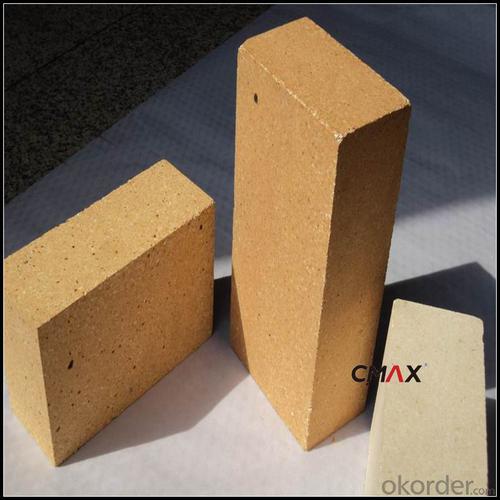

Insulating Fire Brick for Standard Size Insulation Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Light Weight Insulating Brick

CMAX insulating firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay.

The thermal insulation brick is a kind of insulation material adopting organic matter as ignition loss substance in order to increase the porosity of refractory, which has such advantages as high porosity, small volume density, good insulation effect, high mechanical intensity, small thermal conductivity and long service life. For various industrial kilns & furnaces, it is a kind of essential refractory for energy saving and temperature preservation.

Light Weight Insulating Brick Features

1. Containing a large number of closed pores

2. Have a lightweight high temperature

3. Good insulation properties

4. Refiring small contraction

5. Excellent thermal shock resistance

6. Strong resistance to the corrosive gas and slag.

Light Weight Insulating Brick Application

The thermal insulation brick can be in direct contact with the flame, to apply to the cracking furnace, hot stove, furnace, tunnel kiln, push board kiln, crucible furnace and electric furnace, electric kilns lined widely used in metallurgy, refractories, light industry, chemical industry, ceramics, glass, electronics and other industries. Dimensions of the product, the physical and chemical indicators, service life have reached or exceeded the level of similar products at domestic and abroad.

Light Weight Insulating Brick Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: Can insulating fire bricks be used in the construction of thermal insulation roofs?

- Insulating fire bricks are indeed applicable in the construction of thermal insulation roofs. Their design is tailored to possess exceptional thermal insulation characteristics, rendering them a perfect option for heat retention and energy efficiency needs. These bricks are crafted from lightweight materials like clay, which exhibit low thermal conductivity and remarkable resistance to heat transfer. Consequently, they effectively minimize heat loss or gain, making them suitable for thermal insulation roofs. Moreover, insulating fire bricks showcase durability and the ability to endure high temperatures, establishing them as a dependable choice for long-lasting utilization in roofing applications.

- Q: Are insulating fire bricks resistant to moisture or water damage?

- Yes, insulating fire bricks are resistant to moisture or water damage. They are designed to withstand high temperatures and do not absorb water, making them a suitable choice for applications where moisture or water exposure is a concern.

- Q: Can insulating fire bricks be used in the construction of industrial boilers?

- Yes, insulating fire bricks can be used in the construction of industrial boilers. These bricks are designed to withstand high temperatures and provide excellent insulation, making them ideal for use in boiler systems where heat retention and efficiency are crucial. They help to prevent heat loss and ensure efficient energy transfer, making them a popular choice for industrial boiler applications.

- Q: Can insulating fire bricks be used for insulation in power boiler walls?

- Yes, insulating fire bricks can be used for insulation in power boiler walls. Insulating fire bricks are designed to provide excellent thermal insulation, high temperature resistance, and low thermal conductivity. These properties make them suitable for use in power boiler walls, where insulation is crucial to reduce heat loss and improve energy efficiency.

- Q: What are the raw materials used in the production of insulating fire bricks?

- Insulating fire bricks are produced using a blend of alumina, silica, and assorted additives. Alumina is obtained from bauxite ore, which is then processed to extract the alumina content. Silica, on the other hand, is typically sourced from quartz or silica sand. These two substances serve as the primary constituents of insulating fire bricks, granting them exceptional heat resistance and thermal insulation properties. Supplementary to alumina and silica, additional additives may be incorporated into the manufacturing process to enhance specific characteristics of the bricks. For instance, clay can be included to improve the workability and plasticity of the mixture during shaping and molding. Various binders, such as organic or inorganic materials, can also be integrated to fortify the strength and structural integrity of the bricks. Depending on the desired qualities and specific requirements of the insulating fire bricks, other materials may be added as well. These can include zirconium, magnesium, calcium, or other refractory materials. These additives aid in further bolstering the heat resistance, mechanical strength, and insulation properties of the bricks. In summary, the amalgamation of alumina, silica, and other additives gives rise to a composition capable of withstanding high temperatures, offering excellent insulation, and exhibiting commendable structural integrity. Consequently, insulating fire bricks are highly regarded materials in various industries such as metallurgy, ceramics, and kiln construction.

- Q: Can insulating fire bricks be used in the insulation of boilers?

- Indeed, the utilization of insulating fire bricks is possible for the insulation of boilers. These fire bricks are engineered to endure elevated temperatures and exhibit remarkable efficiency in preventing heat transfer. With their low thermal conductivity, they aid in minimizing heat dissipation from the boiler, thereby enhancing its energy efficiency holistically. Moreover, due to their lightweight composition and ease of installation, insulating fire bricks are an optimal selection for boiler insulation.

- Q: Can insulating fire bricks be used in the construction of heat storage systems?

- Yes, insulating fire bricks can be used in the construction of heat storage systems. Insulating fire bricks are designed to have low thermal conductivity, which means they are capable of trapping and storing heat effectively. These bricks are made from materials such as fire clay, which have excellent insulation properties. By using insulating fire bricks, heat loss can be minimized, allowing for efficient heat storage and retention in heat storage systems. The bricks can be used to build the walls and lining of the heat storage system, ensuring that the stored heat is not dissipated to the surroundings. Additionally, insulating fire bricks are lightweight and easy to handle, making them a convenient choice for constructing heat storage systems. Overall, the use of insulating fire bricks in the construction of heat storage systems enhances their thermal efficiency and contributes to more effective heat management.

- Q: Are insulating fire bricks resistant to warping?

- Yes, insulating fire bricks are generally resistant to warping. Insulating fire bricks are designed to withstand high temperatures and thermal shocks, which helps prevent warping. These bricks are made from lightweight materials such as clay, silica, and alumina, combined with additives to enhance their insulating properties. These additives also contribute to the brick's ability to resist warping. Additionally, insulating fire bricks undergo a specific manufacturing process that helps ensure dimensional stability and minimize the risk of warping. However, it's important to note that extreme and prolonged exposure to high temperatures can still cause some degree of warping, but compared to other types of bricks, insulating fire bricks offer a higher level of resistance.

- Q: Can insulating fire bricks be used in high-temperature ducts?

- Yes, insulating fire bricks can be used in high-temperature ducts. Insulating fire bricks are designed to withstand high temperatures and provide thermal insulation, making them suitable for use in ducts where high temperatures are present.

- Q: Are insulating fire bricks resistant to moisture absorption?

- Yes, insulating fire bricks are highly resistant to moisture absorption. They are designed to have low porosity and are made from materials that do not readily absorb water. This makes them ideal for applications where moisture resistance is crucial, such as in kilns, furnaces, and other high-temperature environments.

Send your message to us

Insulating Fire Brick for Standard Size Insulation Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t

- Supply Capability:

- 2000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords