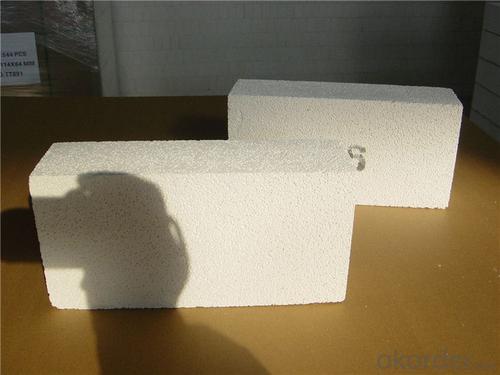

Insulating Fire Brick with Excellent Insulating Effect - Common Size for Heat Treatment Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM conforms strictly to the requirements of ISO 9000 quality control system during the production. MSDS is also available if you want. The thermal insulation fire clay brick meet with the requirements of ASTM & JIS standards. So please stay cool with our quality.

Application

Insulating Fire Brick are used for the lining of converter, alternating current arc furnace, direct Current arc furnace and the ladle slag line, etc.

Insulating Fire Brick Technical index

Brand Quality | JM23 | JM26 | JM28 | JM30 | JM32 | |

Bulk Density (g/cm3) | 0.52 | 0.78 | 0.88 | 1.03 | 1.25 | |

1.2 | 1.6 | 2.1 | 2.5 | 3.5 | ||

Modulus of Rupture (Mpa) | 0.9 | 1.4 | 1.6 | 2.1 | 2.1 | |

-0.5 | 1400℃ -0.4 | 1510℃ -0.5 | 1620℃ -0.9 | 1730℃ -0.9 | ||

Thermal Expansion 1100℃(%) |

0.5 |

0.7 |

0.8 |

0.9 |

1.1 | |

Thermal conductivity(W/m.k)

| 400℃ | 0.14 | 0.27 | 0.32 | 0.41 | 0.49 |

600℃ | 0.16 | 0.29 | 0.34 | 0.43 | 0.50 | |

800℃ | 0.18 | 0.31 | 0.36 | 0.44 | 0.51 | |

1000℃ | 0.20 | 0.33 | 0.38 | 0.45 | 0.53 | |

Al2O3 | 37 | 58 | 67 | 73 | 77 | |

Fe2O3 | 0.7 | 0.7 | 0.6 | 0.5 | 0.4 | |

Equipment

1 unit of Ceramic Abrasive (SG Abrasive) pilot production line

2 units of Compact grain Abrasive pilot production lines

1 unit of high-end coated abrasives (abrasive cloth) production line

2 units of Boron Carbide production lines

3 large flexible crushing and sieving lines for grit production lines

2 units of 2000KVA furnaces for Boron Carbide fusion

6 units of 5000KVA-10000KVA dumping type electric arc furnaces for Brown Fused Alumina fusion

Company Advantage

(1)Long Insulating Fire Brick manufacture history: 25 years manufacturer

(2)Advanced equipment

(3)Diversification of production standards: ISO ANSI FEPA JIS ASTM

(4)Flexible payment: T/T L/C D/P D/A

(5)Professional marketing team and after-sale service

(6)Free sample

FAQs

Q1 |

What’s the transport method? |

A1 | FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo. |

Q2 |

What’s the required payment term? |

A2 | Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation. |

Q3 |

Which country are our products exported to? |

A3 | Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations. |

- Q: What are the main components of insulating fire bricks?

- Insulating fire bricks usually consist of a blend of alumina, silica, and assorted lightweight additives. Alumina (Al2O3) is crucial in insulating fire bricks due to its ability to withstand high temperatures and resist thermal shock. Silica (SiO2) contributes to improving the refractory qualities and insulation abilities of the bricks. Furthermore, vermiculite or perlite, which are lightweight additives, are commonly incorporated to enhance the insulating properties of the bricks. The collaboration of these components produces a material that possesses exceptional thermal insulation, minimal thermal conductivity, and remarkable heat resistance.

- Q: Can insulating fire bricks be used in the construction of radiant tubes?

- Insulating fire bricks are indeed applicable for the construction of radiant tubes. These bricks are specifically crafted to provide exceptional thermal insulation, which makes them extremely suitable for scenarios where heat preservation is crucial. Radiant tubes, on the other hand, are utilized in environments that endure high temperatures, such as furnaces and kilns, where they are exposed to intense heat. By being able to withstand such elevated temperatures, insulating fire bricks aid in minimizing heat loss, thereby leading to enhanced energy efficiency. Moreover, these bricks' insulating properties also serve to safeguard the radiant tubes against thermal shock and extend their lifespan. In summary, incorporating insulating fire bricks into the construction of radiant tubes elevates their overall performance and durability.

- Q: What is the typical flexural strength of an insulating fire brick?

- The typical flexural strength of an insulating fire brick can vary depending on the specific composition and manufacturing process. However, on average, insulating fire bricks have a flexural strength range of 1-10 megapascals (MPa).

- Q: Can insulating fire bricks be used in the insulation of boilers?

- Yes, insulating fire bricks can be used in the insulation of boilers. Insulating fire bricks are designed to withstand high temperatures and are highly effective at insulating against heat transfer. They have low thermal conductivity, which means they can help reduce heat loss from the boiler and improve its overall energy efficiency. Additionally, insulating fire bricks are lightweight and easy to install, making them an ideal choice for boiler insulation.

- Q: Are insulating fire bricks suitable for applications requiring low thermal conductivity?

- Yes, insulating fire bricks are suitable for applications requiring low thermal conductivity. Insulating fire bricks are specifically designed to have low thermal conductivity, making them ideal for situations where heat insulation is necessary. These bricks are made from lightweight and porous materials, such as clay and other refractory materials, which provide excellent insulation properties. The porous structure of insulating fire bricks traps air within the material, reducing heat transfer and resulting in low thermal conductivity. This makes them effective in applications such as kilns, furnaces, and other high-temperature environments where minimizing heat loss is crucial. Overall, insulating fire bricks are a reliable choice for applications that demand low thermal conductivity.

- Q: Can insulating fire bricks be used in the construction of refractory coatings?

- Yes, insulating fire bricks can be used in the construction of refractory coatings. Insulating fire bricks are designed to have low thermal conductivity, making them suitable for insulating applications. When used as a component in refractory coatings, they can help to enhance the insulation properties and provide thermal protection.

- Q: Can insulating fire bricks be used for insulation in boilers?

- Certainly, insulation in boilers can make use of insulating fire bricks. These bricks are specially engineered to endure extreme temperatures and offer exceptional thermal insulation. Their thermal conductivity is minimal, resulting in a significant decrease in heat dissipation and an enhancement in the energy efficacy of boilers. Moreover, insulating fire bricks are lightweight and simple to install, rendering them a favored option for boiler insulation. They aid in preserving elevated temperatures within the boiler, facilitating efficient combustion and heat transfer, while simultaneously shielding the outer framework from excessive heat. All in all, insulating fire bricks are a dependable and efficient alternative for boiler insulation.

- Q: Can insulating fire bricks be used in the construction of coke ovens?

- Yes, insulating fire bricks can be used in the construction of coke ovens. Insulating fire bricks are specially designed to withstand high temperatures and provide excellent thermal insulation. Coke ovens operate at extremely high temperatures, typically around 2000 degrees Fahrenheit, and require materials that can withstand these conditions. Insulating fire bricks have low thermal conductivity, which means they can effectively prevent heat transfer between the oven's interior and exterior. This helps to maintain the high temperatures required for the carbonization of coal in the coke oven, while also minimizing heat loss. Furthermore, insulating fire bricks are lightweight and have high strength, making them ideal for use in the construction of coke ovens. Their lightweight nature allows for easier installation and reduces the overall weight of the structure. Their high strength ensures that they can withstand the harsh operating conditions of the coke oven without cracking or crumbling. In summary, insulating fire bricks are a suitable choice for the construction of coke ovens due to their ability to withstand high temperatures, provide thermal insulation, and offer durability.

- Q: How thick should the insulation layer be when using insulating fire bricks?

- The thickness of the insulation layer when using insulating fire bricks depends on various factors such as the desired level of insulation, the temperature of the surrounding environment, and the specific application or purpose of the insulation. In general, insulating fire bricks are designed to provide excellent thermal insulation, which means they are capable of reducing heat transfer effectively. However, the thickness of the insulation layer should be determined based on the specific requirements of the project. For applications where high-temperature insulation is needed, a thicker layer of insulating fire bricks is typically recommended. This is because a thicker layer can provide better insulation and reduce heat loss more effectively. Additionally, a thicker insulation layer can also enhance the overall structural integrity of the insulation system. On the other hand, for applications where lower temperature insulation is needed or for projects with space constraints, a thinner layer of insulating fire bricks may be sufficient. In such cases, it is important to consider the specific thermal conductivity properties of the insulating fire bricks being used and ensure that the desired insulation requirements are met. It is also worth noting that insulation requirements may vary based on local building codes, safety regulations, and industry standards. Therefore, it is advisable to consult with professionals or experts in the field to determine the optimal thickness of the insulation layer when using insulating fire bricks for a specific project.

- Q: Can insulating fire bricks be used in sewage treatment plants?

- Indeed, insulating fire bricks can find their application in sewage treatment plants. These bricks are specifically engineered to possess exceptional thermal insulation properties, rendering them suitable for high-temperature scenarios. Within sewage treatment plants, various processes necessitate the utilization of heat, such as anaerobic digestion or sludge incineration. Consequently, insulating fire bricks can be employed to encase the walls, floors, and roofs of incinerators or digesters, thereby facilitating the retention of generated heat and enhancing energy efficiency. Moreover, sewage treatment plants often confront corrosive and abrasive surroundings as a result of the presence of chemicals, acids, and solids within the wastewater. Notably, insulating fire bricks are forged from top-notch refractory materials, boasting resistance against chemical assault and erosion. This characteristic endows them with suitability for lining tanks, pipes, or other equipment that may come into contact with corrosive substances. Furthermore, owing to their lightweight nature, insulating fire bricks prove to be more manageable and straightforward to install in comparison to alternative types of refractory materials. This aspect can be particularly advantageous in sewage treatment plants where the need for frequent maintenance or repairs may arise. All in all, insulating fire bricks stand as a versatile and long-lasting choice for implementation within sewage treatment plants. They offer exceptional thermal insulation, resilience against corrosive environments, and ease of installation.

Send your message to us

Insulating Fire Brick with Excellent Insulating Effect - Common Size for Heat Treatment Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords