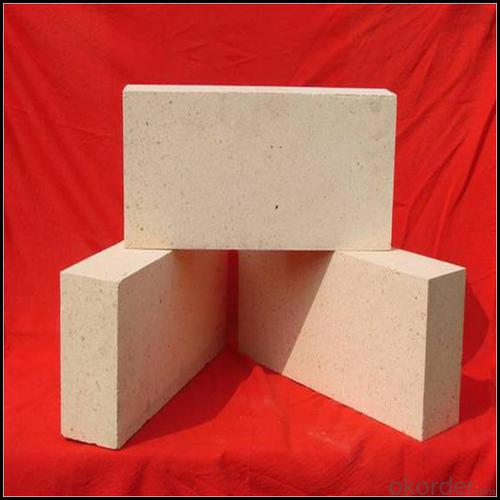

Insulating Fire Brick - Acid Resistant Standard Size Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 1800 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Refractory Brick

CMAX firebricks are classified under temperature between 1300℃ to 1700℃, manufactured from high purity alumina clay by mixing, press-forming, drying, sintering and machining. Bricks contain carefully-graded organic fillers which are burned out during sintering to give a uniform controllable pore structure. This technique makes product feature low thermal conductivity and excellent heat insulation

Features

a) Low thermal conductivity;

b) High refractoriness;

c) High mechanical strength;

d) Excellent thermal shock resistance;

e) Non standard sizes and shapes are available upon request.

Application

Light Weight Mullite Insulation Brick can be widely used for lining or insulation layers of various industrial furnaces and kilns in metallurgical industry, machine building industry, ceramic industry, chemical industry.

Data Sheet

Classification Temperature (℉/℃) | 3000/1650 |

Bulk Density (g/cm3 ) | ≤1.0 |

Thermal Conductivity | |

800℃, W/m.K | ≤0.39 |

1000℃, W/m.K | ≤0.43 |

1200℃, W/m.K | ≤0.48 |

Reheating Linear Change (%) | 1550℃×12h |

≤0.9 | |

Chemical Composition (%) | |

Al2O3 | ≥75 |

Fe2O3 | ≤0.5 |

Packaging & Shipping

Packaging Details:Be packed in fumigated wooden pallets

Delivery Detail: 30 days after order

Our Services

Optimum solution and product supply of refractories for high temperature industries, such as iron steel, non-ferrous, petrochemical and building materials.

Engineering design, contract and consult for refractories, and civil architecture design.

Research, development, manufacture and sale of superhard materials.

R&D, manufacture and sale of special packing materials for export.

Inspection, supervision and arbitration of refractories.

Consultation and services in refractories information.

Training and cultivation of high-level talents in refractories profession

Sales Network

Company Information

CNBM (China National Building Material) Group is the largest comprehensive building materials group in China that in integrate scientific research, manufacturing and logistics into one entity. The largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields, CNBM is playing the leading role in the building industry in the country.

FAQ

1. Which products do you have?

We have all kinds of refractory brick, castable, mortar, cement, ceramic fiber products, etc.

Or you could browse our products to choose what you need.

2. Can you give me a brief introduction of the application of your products?

We are mainly specializing in the refractory materials in iron and steel, cement, glass, ceramics, petrochemical, electric power Industry, etc.

3. If I need your offer, what information do you need?

In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc. If any question, please contact us freely.

- Q: How do insulating fire bricks provide thermal insulation?

- The unique composition and structure of insulating fire bricks enable them to provide thermal insulation. These bricks utilize lightweight materials like clay, shale, and other minerals, which possess low thermal conductivity. As a result, they are not easily conductive of heat, serving as an effective barrier against heat transfer. Furthermore, insulating fire bricks are intentionally designed to have a porous structure. This design incorporates small air pockets within the bricks, effectively reducing the conduction of heat. These air pockets function as a barrier, effectively restricting the movement of heat from one side of the brick to the other. Moreover, insulating fire bricks possess a high melting point, rendering them suitable for high-temperature applications. This characteristic allows the bricks to endure extreme heat without undergoing deformation or breakdown, ensuring long-lasting thermal insulation. To summarize, the low thermal conductivity, porous structure, and high melting point of insulating fire bricks collectively contribute to their ability to provide thermal insulation. These attributes work in unison to minimize heat transfer, making them an excellent choice for situations requiring thermal insulation.

- Q: Can insulating fire bricks be used for insulation in sewage treatment plants?

- Yes, insulating fire bricks can be used for insulation in sewage treatment plants. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent insulation, making them suitable for use in environments where heat and moisture are present, such as sewage treatment plants. These bricks have low thermal conductivity, which helps to reduce heat loss and increase energy efficiency in the treatment process. Additionally, their resistance to chemicals and moisture makes them ideal for withstanding the corrosive environment found in sewage treatment plants. Therefore, insulating fire bricks can effectively provide insulation in sewage treatment plants, helping to maintain optimum operating temperatures and improve overall efficiency.

- Q: Can insulating fire bricks be used in ceramic industry kilns?

- Yes, insulating fire bricks can be used in ceramic industry kilns. These bricks are designed to withstand high temperatures and provide excellent insulation, making them suitable for use in kilns where high heat retention and energy efficiency are important.

- Q: Can insulating fire bricks be used in the construction of flue gas ducts?

- Yes, insulating fire bricks can be used in the construction of flue gas ducts. Insulating fire bricks are specifically designed to withstand high temperatures and provide excellent thermal insulation. This makes them a suitable choice for lining flue gas ducts, as they can help to reduce heat loss and improve energy efficiency. Additionally, insulating fire bricks are resistant to chemical corrosion and can withstand the corrosive effects of flue gases. However, it is important to ensure that the insulating fire bricks used are specifically designed for flue gas duct applications and meet the necessary safety and regulatory requirements. Consulting with a professional engineer or specialist in the field is recommended to ensure the correct selection and installation of insulating fire bricks in flue gas ducts.

- Q: What's the price of lightweight refractory bricks?

- Insulation bricks according to size, material, performance of different prices are not the same, the same products in different regions also vary slightly

- Q: Are insulating fire bricks resistant to weathering?

- Yes, insulating fire bricks are resistant to weathering. Insulating fire bricks are made from high-quality refractory materials that are designed to withstand extreme temperatures and harsh weather conditions. They are specifically engineered to have excellent resistance to thermal shock, erosion, and corrosion caused by exposure to various weather elements such as rain, snow, wind, and sunlight. Additionally, insulating fire bricks are also resistant to chemical attacks, making them highly durable and suitable for long-term use in outdoor applications. Overall, their robust composition and resistance to weathering make insulating fire bricks a reliable choice for insulation and construction purposes in outdoor environments.

- Q: Can insulating fire bricks be used in the construction of industrial furnaces?

- Indeed, the utilization of insulating fire bricks is viable in the creation of industrial furnaces. These bricks are specifically engineered to endure elevated temperatures and thermal shocks, rendering them suitable for deployment in furnaces operating at exceedingly high levels of heat. Their thermal conductivity is notably low, thereby reducing heat dissipation and enhancing the energy efficiency of the furnace. Moreover, these fire bricks exhibit a lightweight composition and are effortlessly maneuverable, thereby proving to be convenient for construction endeavors. In summary, the superb insulation capabilities and heat-resistant attributes of insulating fire bricks position them as an optimal selection for the construction of industrial furnaces.

- Q: Are insulating fire bricks resistant to reducing atmospheres?

- Yes, insulating fire bricks are resistant to reducing atmospheres.

- Q: How do insulating fire bricks affect the overall efficiency of a heating system?

- The efficiency of a heating system is greatly improved by insulating fire bricks, which have a crucial role to play. These bricks are specifically designed to have low thermal conductivity, allowing them to effectively trap and retain heat within the system. The use of insulating fire bricks significantly reduces heat loss from the system, resulting in improved energy efficiency. One of the main advantages of insulating fire bricks is their ability to minimize heat transfer through conduction. These bricks have a high resistance to heat flow, acting as a barrier that prevents heat from escaping the system. This is particularly important in areas where high temperatures are generated, such as furnaces or kilns. By containing the heat within the system, insulating fire bricks enable the heating system to maintain a consistent temperature, reducing the need for excessive energy consumption to compensate for heat loss. In addition, insulating fire bricks also help decrease heat loss through radiation. These bricks have a high emissivity, meaning they radiate less heat than other materials. As a result, the heat produced by the system is focused on the desired area, rather than being wasted through radiation. This not only improves the efficiency of the heating system but also ensures that the heat is effectively utilized for its intended purpose. Another advantage of insulating fire bricks is their ability to withstand high temperatures without deteriorating. These bricks are composed and manufactured in a way that allows them to handle extreme heat levels, maintaining their structural integrity over time. This durability is crucial for the longevity of the heating system and ensures that the insulating properties of the bricks remain intact. To summarize, insulating fire bricks have a significant positive impact on the overall efficiency of a heating system. Their low thermal conductivity, ability to minimize heat transfer through conduction and radiation, and durability at high temperatures all contribute to reducing heat loss and improving energy efficiency. By incorporating insulating fire bricks into a heating system, users can enjoy a more efficient and cost-effective heating solution.

- Q: Can insulating fire bricks be used in wastewater treatment plants?

- Yes, insulating fire bricks can be used in wastewater treatment plants. Insulating fire bricks are designed to withstand high temperatures, making them suitable for use in various industrial applications, including wastewater treatment plants. They are commonly used in the construction of kilns, furnaces, and other high-temperature equipment. In wastewater treatment plants, insulating fire bricks can be used in the construction of incinerators, thermal oxidizers, and other systems that require high-temperature insulation. Their properties, such as high thermal resistance, low thermal conductivity, and excellent insulation capabilities, make them ideal for maintaining the desired temperatures in these systems while minimizing heat loss. Additionally, insulating fire bricks are resistant to chemical attacks, which is important in wastewater treatment plants where various chemicals and corrosive substances are present. Overall, the use of insulating fire bricks in wastewater treatment plants can help improve energy efficiency, reduce maintenance costs, and ensure the longevity of high-temperature equipment.

Send your message to us

Insulating Fire Brick - Acid Resistant Standard Size Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 1800 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords