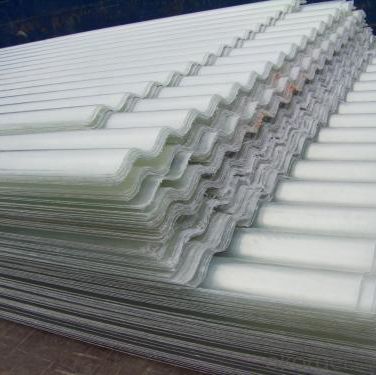

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions.

FEATURES

>> Weatherability: In the temperature range of -40 ℃ - 120 ℃ to maintain stable performance, no high-temperature softening, cold brittle phenomenon;

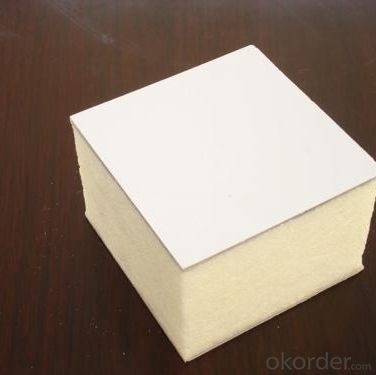

>> Low thermal conductivity & good insulation performance;

>> Non-toxic, non-asbestos, etc., in line with world health standards;

>> No moss & prevent microbial growth;

>> High impact and resistant to strong wind;

>> Safe and reliable, Not combustion-supporting in open fire;

>> Corrosion resistance, suitable for chemical workshop roof, such as fertilizer plants, electroplating factory

SPECIFICATIONS

Item | Description | ||

| Material | FRP, ASA, PVC | ||

| Thickness | 1.0mm - 3.0mm | ||

| Color | Clear, milk white, blue, green, red | ||

| Type | 475, 666, 760, 820, 840, 860, 900, 950, 980, 1050, can be customized | ||

| Shelf life | 15 years | ||

PICTURES

- Q: Can FRP roofing panels be used in breweries or distilleries?

- Certainly! Fiberglass Reinforced Plastic (FRP) roofing panels are applicable for implementation within breweries or distilleries. Acknowledged for their outstanding durability and resistance to corrosion, FRP panels are apt for settings possessing elevated moisture levels and chemical exposure, such as breweries and distilleries. Furthermore, FRP panels are lightweight, simple to install, and can deliver exceptional insulation properties, which are vital for sustaining a regulated environment during brewing or distilling procedures. All in all, FRP roofing panels are a dependable and economically viable selection for these industries, furnishing enduring performance and safeguarding against diverse environmental elements.

- Q: Can FRP roofing panels be used in concert venues or stadiums?

- Yes, FRP roofing panels can be used in concert venues or stadiums. FRP (Fiberglass Reinforced Plastic) roofing panels are lightweight, durable, and weather-resistant, making them suitable for large structures like concert venues or stadiums. They offer excellent strength and can withstand the elements, making them a reliable choice for such applications. Additionally, FRP panels can be easily customized to fit the specific design requirements of the venue or stadium.

- Q: Are FRP roofing panels resistant to stains from air pollution or industrial emissions?

- FRP roofing panels, commonly referred to as Fiberglass Reinforced Plastic, generally exhibit resistance to stains resulting from air pollution or industrial emissions. These panels are renowned for their durable nature and ability to withstand various environmental elements, including exposure to chemicals. The smooth and non-porous surface of FRP panels prevents easy absorption of stains or pollutants. Moreover, these panels are often coated with a protective layer to further enhance their resistance against staining. It is important to acknowledge, however, that the level of resistance may vary depending on the specific composition and quality of the FRP panels. In conclusion, FRP roofing panels can be relied upon to effectively endure stains caused by air pollution or industrial emissions.

- Q: Are FRP roofing panels resistant to snow and ice buildup?

- FRP roofing panels, known as Fiberglass Reinforced Plastic, are generally resistant to the accumulation of snow and ice. The properties of FRP make it a suitable material for enduring harsh weather conditions. The smooth surface of FRP panels prevents snow and ice from sticking, thus reducing the buildup of these elements. Moreover, the lightweight quality of FRP panels lessens the risk of structural harm caused by heavy snow or ice loads. Nevertheless, it is important to acknowledge that no roofing material is entirely impervious to snow and ice accumulation. In extreme weather conditions, it is advised to regularly remove snow and ice from the roof to prevent any potential damage.

- Q: Do FRP roofing panels require specific safety precautions during installation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require specific safety precautions during installation. Firstly, it is important to ensure that all necessary safety equipment is provided and used by the installers. This includes items such as safety harnesses, hard hats, gloves, goggles, and non-slip footwear. These safety measures are crucial to protect installers from potential falls, head injuries, hand injuries, and eye injuries. Secondly, it is important to follow proper handling and lifting techniques when working with FRP roofing panels. These panels can be heavy and awkward to maneuver, so it is important to have enough manpower and use appropriate lifting techniques to prevent strains and other lifting-related injuries. Furthermore, it is important to be cautious of the potential for electrical hazards during installation. FRP roofing panels are often installed on structures that may have electrical wiring or equipment nearby. Installers should be trained to identify and avoid electrical hazards, and it may be necessary to shut off power to certain areas during installation to minimize the risk of electric shock. Lastly, it is crucial to follow the manufacturer's guidelines and instructions for installation. FRP roofing panels may have specific requirements for installation, such as recommended temperatures, adhesives, or fasteners. By following these guidelines, installers can ensure that the panels are properly installed and minimize the risk of accidents or structural failures. In conclusion, FRP roofing panels do require specific safety precautions during installation. By providing and using the necessary safety equipment, following proper handling and lifting techniques, being cautious of electrical hazards, and following manufacturer's guidelines, installers can ensure a safe and successful installation process.

- Q: Are FRP roofing panels resistant to fading or discoloration?

- Yes, FRP roofing panels are generally resistant to fading or discoloration due to their durable construction and protective coatings.

- Q: Are FRP roofing panels prone to cracking or warping?

- The durability and resistance to cracking or warping are characteristics commonly associated with FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess remarkable strength and structural integrity due to their composition of fiberglass and plastic. In comparison to materials like wood or metal, FRP panels exhibit a relatively low coefficient of expansion. Consequently, they undergo minimal expansion and contraction when subjected to temperature fluctuations, thereby reducing the likelihood of cracking or warping. Furthermore, the fiberglass reinforcement incorporated into FRP panels enhances their strength and rigidity, rendering them less vulnerable to damage caused by impacts or heavy loads. This attribute makes them a favored option for industrial and commercial environments, where durability is of utmost importance. Nevertheless, it is crucial to acknowledge that the quality of FRP panels can vary based on the manufacturer and specific production process. Inferior panels or those not installed correctly may be more susceptible to cracking or warping. Hence, it is imperative to select a reputable manufacturer and ensure proper installation to optimize the longevity and performance of FRP roofing panels.

- Q: Can FRP roofing panels be used for outdoor structures?

- Outdoor structures can indeed utilize FRP (Fiber Reinforced Plastic) roofing panels. Renowned for their sturdiness, robustness, and ability to withstand diverse weather elements like UV rays, rain, and wind, FRP roofing panels are specifically engineered to endure challenging outdoor conditions, ensuring exceptional safeguarding for various structures. They are frequently employed in outdoor settings, including patios, pergolas, carports, sheds, and agricultural buildings. Apart from their exceptional resistance to weather, FRP roofing panels possess the advantages of being lightweight, easy to install, and having a long lifespan. All in all, FRP roofing panels present a dependable and pragmatic choice for outdoor structures.

- Q: Can FRP roofing panels be installed on boat docks or marinas?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on boat docks or marinas. FRP roofing panels are known for their durability, resistance to corrosion, and long lifespan, making them a suitable choice for these environments. Boat docks and marinas are exposed to harsh weather conditions, including sunlight, moisture, and saltwater, which can cause damage to traditional roofing materials. However, FRP roofing panels are specifically designed to withstand these elements, making them an ideal option for boat docks and marinas. Additionally, FRP panels are lightweight, easy to install, and require minimal maintenance, making them a practical choice for these applications.

- Q: Are FRP roofing panels suitable for agricultural buildings?

- Yes, FRP (fiberglass reinforced plastic) roofing panels are suitable for agricultural buildings. FRP panels offer numerous benefits that make them a popular choice for agricultural applications. Firstly, FRP panels are lightweight, durable, and strong, making them capable of withstanding heavy loads, such as snow or hail, without buckling or collapsing. This is particularly important for agricultural buildings as they often require a sturdy roof to protect livestock, equipment, or crops. Additionally, FRP panels are resistant to corrosion, rust, and chemicals commonly found in agricultural environments, such as fertilizers and animal waste. This resistance ensures that the panels will maintain their integrity and functionality over time, reducing the need for frequent maintenance or replacement. Another advantage of FRP panels is their excellent thermal insulation properties. They can help regulate the temperature inside the agricultural building, keeping it cooler in summer and warmer in winter. This is particularly beneficial for livestock or crop storage, as it helps create a comfortable and controlled environment. Furthermore, FRP panels are also UV resistant, meaning they can withstand prolonged exposure to sunlight without degrading or discoloring. This is crucial for agricultural buildings that are often exposed to harsh weather conditions, including intense sunlight. In summary, FRP roofing panels are highly suitable for agricultural buildings due to their lightweight yet sturdy construction, resistance to corrosion and chemicals, thermal insulation properties, and UV resistance. These features ensure that FRP panels can provide long-lasting protection and durability in agricultural environments, making them an excellent choice for farmers and agricultural building owners.

Send your message to us

Insulated FRP Laminated Roof Panels - FRP GRP Fiberglass Glassfiber Corrugated Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords