FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

Fibreglass / Fiberglass Reinforced Plastic (FRP) or Glass Fiber Reinforced Plastic (GRP) is composed of thermosetting plastics and reinforced fiberglass, Greater than that of steel products and aluminum products in specific tenacity. Products in the ultra-low temperature or high temperature will not happen brittle fracture, deformation and to prevent heat transfer. Corrosion products in the environment anti-aging, yellowing resistance, corrosion resistance, friction resistance, easy to clean. Can be instead of aluminum, stainless steel plates, tiles and so on.

FEATURES

1.corrosion resistance no rust, no maintenance, long service life.

2.lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%), the one way than intensity and stiffness is quite prominent, the density of glass fiber reinforced plastic is only about a quarter of the steel, light weight, very easy to handle, so as to reduce the handling fee.

3..Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

4.anti-aging select highquality FRP pultrusion profiles, the service life of the product can reach more than 20 years, and in all the pultrusion FRP profiles were added in the formula of an-uv agent in order to get the best anti-uv effect.

5.excellent electromagnetic performance it has excellent electrical insulation, electrical, magnetic and electric spark can be used in risk conduction,

sensitive to magnetic equipment area, and flammable and explosive place.

SPECIFICATION

| Product Details | |

| Brand | CMAX |

| Model NO. | BQ-1111 |

| Color | Any Pantone color or multi-colors can be customized. |

| Size | Length: any length you want |

| width: 660mm | |

| thickness: 3mm | |

| surface | glossy |

| MOQ: | 50 meter |

| Payment Term: | TT(Telegraphic Transfer),L/C(letter of credit), Paypal, western union, HSBC Hong Kong. |

| Production Capacity: | 70000pcs Per week |

| Shipping | DHL,FEDEX |

| Additional term | 1. Any customized shape and size are available. 2. If necessary,we will provide some professional suggestion for your reference. |

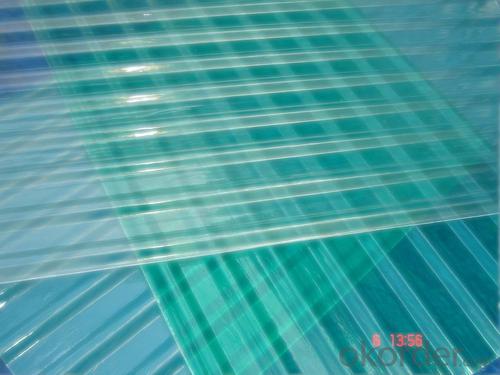

PICTURES

- Q: Can FRP roofing panels be curved or molded?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be curved or molded to fit specific shapes and designs. FRP panels are flexible and can be easily formed to match the desired curvature or contour. This makes them suitable for applications where a curved or molded roof design is desired, such as in architectural projects or specialty roofing installations. Additionally, the lightweight nature of FRP panels makes it easier to manipulate and shape them into the desired form. However, it is important to note that the extent to which FRP panels can be curved or molded may depend on the specific thickness and flexibility of the panel. It is recommended to consult with the manufacturer or a roofing professional to ensure proper installation and compatibility with the desired design requirements.

- Q: Are FRP roofing panels resistant to bird nesting or infestations?

- Yes, FRP roofing panels are generally resistant to bird nesting or infestations. The smooth and non-porous surface of FRP panels makes it difficult for birds to build nests or find areas to infest. Additionally, FRP panels are often designed to be durable and resistant to damage, minimizing the risk of birds penetrating the material.

- Q: Are FRP roofing panels suitable for flat roofs?

- Yes, FRP roofing panels are suitable for flat roofs. They are a durable and lightweight option that provide excellent protection against weather elements, making them ideal for flat roof applications. Additionally, FRP panels offer good insulation properties and are resistant to corrosion, making them a reliable choice for flat roof installations.

- Q: Can FRP roofing panels be installed on retail shopfronts or storefronts?

- Yes, FRP roofing panels can be installed on retail shopfronts or storefronts. These panels are lightweight, durable, and have excellent weather resistance, making them a suitable choice for commercial applications. Additionally, FRP panels offer aesthetic appeal with a variety of colors and finishes available, enhancing the overall appearance of the shopfront or storefront.

- Q: Can FRP roofing panels be used in areas with high levels of industrial emissions?

- FRP roofing panels are generally suitable for use in areas with high levels of industrial emissions. These panels are renowned for their durability and resistance to various chemicals, making them well-suited for harsh environments, including those with industrial emissions. However, it is crucial to take into account the specific type and concentration of industrial emissions in the area. Certain emissions, such as acidic gases or corrosive particles, may necessitate additional protective coatings or special formulations of FRP to ensure long-lasting performance. Consulting with FRP manufacturers or technical experts is also advisable. They can provide tailored guidance based on the nature of the industrial emissions and the intended use of the FRP roofing panels. Furthermore, regular maintenance and inspections should be carried out to evaluate any potential degradation or damage caused by the industrial emissions, ensuring the continuous effectiveness of the FRP roofing system.

- Q: Can FRP roofing panels be used for car washes?

- Indeed, car washes can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels find widespread utilization in industrial and commercial settings, such as car washes, owing to their robustness, potency, and ability to withstand an array of chemicals and weather conditions. Renowned for their capacity to endure moisture, UV rays, and extreme temperatures, FRP panels prove to be optimal for car wash environments that experience constant exposure to water, cleaning solutions, and sunlight. Furthermore, these lightweight panels are effortless to install and demand minimal upkeep, thereby augmenting their appropriateness for car wash applications.

- Q: Do FRP roofing panels require a specific type of ventilation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require a specific type of ventilation. Proper ventilation is essential to ensure the longevity and performance of FRP roofing panels. FRP panels tend to expand and contract with temperature changes, and without proper ventilation, this can lead to warping, cracking, or even failure of the panels. The specific type of ventilation required for FRP roofing panels is known as ridge ventilation. Ridge vents are installed at the peak of the roof to allow hot air to escape from the attic or the space under the roof. This type of ventilation creates a continuous flow of air, preventing the buildup of heat and moisture that can damage the FRP panels. In addition to ridge ventilation, it is also important to have proper soffit or eave vents to allow fresh air to enter the attic or space under the roof. This creates a balanced airflow that helps to regulate temperature and moisture levels, further protecting the FRP roofing panels. It is worth noting that the specific ventilation requirements may vary depending on the specific manufacturer's recommendations or local building codes. Therefore, it is always advisable to consult the manufacturer's guidelines or seek professional advice to ensure that the FRP panels are properly ventilated for optimal performance and longevity.

- Q: Can FRP roofing panels be used for both residential and commercial patio covers?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for both residential and commercial patio covers. FRP roofing panels are durable, lightweight, and highly resistant to weathering, making them suitable for a wide range of applications. They offer excellent protection against UV rays, rain, and other weather elements, making them ideal for outdoor structures like patio covers. Additionally, FRP panels are available in a variety of colors and styles, allowing for customization to match the aesthetic requirements of both residential and commercial spaces. Whether it's a small residential patio cover or a large commercial outdoor seating area, FRP roofing panels can provide a sturdy and long-lasting solution.

- Q: What is the insulation value of FRP roofing panels?

- The insulation value of FRP roofing panels can vary depending on the specific type and thickness of the panels. However, generally, FRP roofing panels have a lower insulation value compared to other roofing materials such as insulated metal panels or foam panels.

- Q: Are FRP roofing panels suitable for hospitals?

- Hospitals can indeed utilize FRP (Fiberglass Reinforced Plastic) roofing panels as they offer several advantages that make them an excellent option for healthcare facilities. To begin with, the durability and longevity of FRP roofing panels are noteworthy. They exhibit resistance to corrosion, weathering, and UV rays, ensuring their structural integrity remains intact over time. This is particularly crucial for hospitals as it enables the roofing system to withstand adverse weather conditions and potential damage from external factors. Moreover, the lightweight nature of FRP roofing panels simplifies both installation and maintenance processes. This can be highly advantageous for hospitals as it minimizes disruptions during installation and any future upkeep or repairs. In addition, FRP roofing panels possess exceptional thermal insulation properties, allowing them to effectively regulate the internal temperature of the hospital. This ensures a comfortable environment for both patients and staff. Additionally, the soundproof qualities of FRP panels contribute to reducing noise pollution in critical areas such as operating rooms and patient rooms. Furthermore, FRP roofing panels exhibit a strong resistance to fire, boasting a high fire resistance rating. This is of utmost importance for hospitals, guaranteeing the safety of patients and staff. In the event of a fire, FRP panels aid in containing the spread and minimizing damage. Lastly, the availability of FRP roofing panels in various colors and finishes grants hospitals the freedom to choose designs that align with their aesthetic preferences. This contributes to creating a pleasant and soothing atmosphere for patients, which is essential for their well-being and recovery. In conclusion, the durability, lightweight nature, thermal insulation properties, fire resistance, noise reduction capabilities, and aesthetic options make FRP roofing panels a practical and reliable choice for hospitals.

Send your message to us

FRP Roofing Panel - High Strength Fiberglass Corrugated Roofing Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords