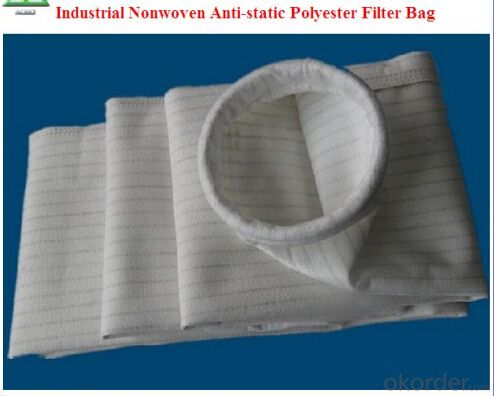

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

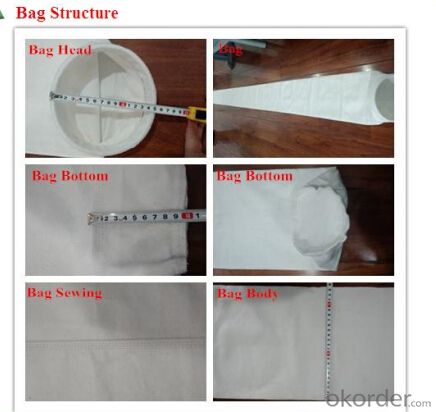

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

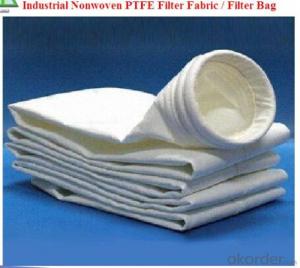

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Antistatic Constructions

electrical conductive

Optimum discharge of electrostatic charges, therefore suitable for potentially explosive areas, as well as for electrostatic, strongly chargeable/charged dusts.

permanent electrical conductive in accordance with DIN 54 345 part 1 by adding stainless steel fibres into the fibre mass in accordance with DIN 54 345 part 1 or

alternative in support of scrim in accordance with DIN 54 345 part 1 and part 5

Packaging & Shipping

Company Information

- Q: What is the line on the top of the filter bag?

- Among them, the satin weave is glossy, smooth, soft, flexible, breathable and easy to remove dust from cloth bags.

- Q: Liquid filter bags should be aware of those items when installing

- Make sure the edge of the filter is cleared. Check the arcs and edges of the tennis basket. The upper edge of the net must be flat on the surface of the filter. If there are no nets or nets, there will be a filter failure. To install a new filter bag, the filter bag must be inserted into the net, and the bag sealing ring must be placed in the seal slot correctly.

- Q: How do you use a filter bag?

- Fifth, replace the filter bag, blow clean with compressed air first, check for broken holes, and then replace when the holes are repaired. If the filter bag is filled with dust, rinse with water and leave after cooling. Sixth, the filter bag is blocked. When the filter bag is blocked, the resistance is raised, but the reading of the differential gauge is displayed. The filter bag jam is the main cause of the wear, perforation and loss of the filter bag.

- Q: What is the reason for the dust bag to be broken for a period of time

- This is a regular change. Bad quality is a good thing,Or it will be broken for too long.

- Q: How to choose a liquid filter bag

- 1, first of all, according to the chemical name to filter the fluid, according to the chemical with taboo to find available filter material, commonly used in PE, PP, PTFE, NMO, again according to its operating temperature, operating pressure, ph, operating conditions (such as whether to need to tolerate steam, hot water or chemical sterilization, etc.), assessed and eliminate shall not apply to the filter material. Use is also an important consideration, such as pharmaceutical, food or cosmetic ingredients that must be approved by the FDA; Ultra-pure water should be chosen for pure and not contain the filter material that will affect the impedance. Filter gases should be selected for hydrophobic materials and whether "health grade filtering" design is required. The main foreign Filter bags are GAF, FSI, 3M, CUNO, U.S. Filter, LOEFFLER, PARK, Vablue Filter bag etc

- Q: Is there a filter bag for the washer?

- A cylinder washer is not a filter bag. And there's no drain valve, but he has a pump. So where did the dirt go? You can look at the structure of the drainage pump first.In fact, he is a vane pump, so the dirt not sensitive, general MAO flocculant, can be directly into the sewer, there is no need to filter bag, larger smudgy, can open the cover to remove. The experience I've been using for a decade or so is that there is no such thing at all

- Q: What materials are commonly used in liquid filtration bags?

- Chemical etch is good, acid and alkali resistance. The filtration efficiency is high, can reach more than 99.5% Expanding filter cloth (bag), improving filter wind speed and filtration efficiency, reducing the volume of dust removal equipment

- Q: What do you notice when the filter bag and dust collector are installed?

- Installation filter filter bag filter bag method is to filter by housing plate hole into the bag in the room, and then put the upper mouth of the spring coil to knead into a pit, in the case of orifice plate medium, neutralizing spring coil again, make it tight pressure tight in the hole on the circumference of a circle, finally the bag cage from mouth gently insert, until the upper part of the filter bag cage cover is pressure on the casing plate hole.

- Q: Can liquid filtration bags be cleaned and reused

- Surface filter mainly adopts nylon monofilament filter bag, metal wire mesh filter bag), the surface of the filter the way for the hole interception, the interception of impurities in the filter material surface, the surface of the filter can be cleaned and secondary use. Remind: liquid filter bag this is a one-time product, under normal circumstances do not recommend repeated use, repeated use of a filter bag filter failure caused easily, at the same time also can cause cross contamination.

- Q: Is it better to dust the air with a filter or a filter?

- Each has its own characteristics and USES to choose according to the use case. The filter bag is characterized by processing power, which has little effect on the flow rate of gas and long life.

Send your message to us

Industrial Nonwoven Needle punched Anti-static Polyester Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords