Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

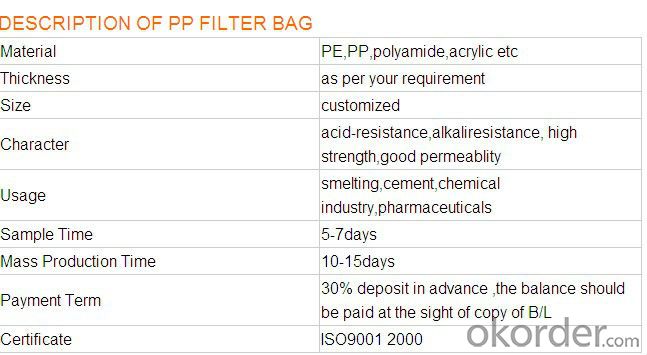

1. Description of Non woven Fiberglass Dust Filter Bag Dust Collector

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Non woven Fiberglass Dust Filter Bag Dust Collector

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Non woven Fiberglass Dust Filter Bag Dust Collector

Weight(g/m2) | 500~550 | |

Thickness(mm) | 2.3~2.5 | |

Air permeability(m3/ m2/min) | 14~8 | |

Tension at break (N/5×20cm) | Warp | >900 |

Weft | >1200 | |

Elongation at break (%) | Warp | <35< span=""> |

Weft | <50< span=""> | |

Working temperature (℃) | Continuous | 130 |

Instantaneous | 150 | |

Anti-acid | Good | |

Anti-alkali | Common | |

Anti-abrasion | Good | |

Post treatment | Thread burning,surface smoothing or coating etc | |

4. Application fields

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

5. Images of Non woven Fiberglass Dust Filter Bag Dust Collector

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: In what aspects is it convenient to choose the filter bag?

- Select dust filter bag by dust collector. Mechanical vibration type dust collector. The filter is thin and smooth, and the texture is soft, which is good for the filter bag of the vibration wave. Anti-blowing bagged dust collector. Should choose the texture soft, the structure is stable, wear-resistant good filter bag. Pulse bag filter. Usually the external filter bag with a frame is used. The requirement is thick, wear-resisting, anti-tension.

- Q: What is the line on the top of the filter bag?

- The plain tissue, which is difficult to clean up dust and easy to clog, is rarely used in the removal of dust

- Q: Whether the washing machine filter bag is damaged or not

- It doesn't affect the filter bag that can only filter the washing in a wash bucket

- Q: What do you do when the washing machine is connected to a filter bag

- Remove the filter bags, remove the wheels and use the thick wire channel

- Q: What is the reason for the dust bag to be broken for a period of time

- Hot or hot? 1, the quality of filter cloth has problems, premature ageing. The operating cycle is over, the filter is aged. 3, flue gas overtemperature, cloth damage. 4, the filter bag is contaminated by oil or the flue gas belt water, the filter bag fails.

- Q: How many types of filters are in the filter bag?

- Flat: the filter bag is flat, including rectangle and trapezoid, which is represented by the perimeter of the length.

- Q: How can you not damage the filter bag when the filter bag is installed?

- The dust filter bag has a great effect on the dust removal effect, and the filter bag must not be damaged by the installation. 1 should pack the filter bags to the installation location and install one of them. The filter bag cannot be dragged carelessly on the board, to prevent the metal burrs from the surface of the filter bag, and damage the filter bag. Remove from the packing box until it is installed to the orifice of the flower plate, not touching any metal or surface roughness. Use the protective cover provided by the supplier when using the orifice, in case the filter is touching the plate hole.

- Q: How does the filter bag work?

- Mechanical vibration wave sootblower is often used in small single cartridge filter, it is the use of filter plate produced by the eccentric gear on shaking power to clear the ash, this action need downtime after operation.

- Q: What is the filter bag for the washing machine?

- We always see something fluffy in our clothes when we wear clothes, and the washing machine filters the stuff!

- Q: What do you notice when the filter bag and dust collector are installed?

- The installation of the filter bag cage is the most careful in all installation and work carefully, so should last for installation, the installation, the bag must not delimit with sharp hard object collisions, hook, even minor scratches, also can make greatly reduces the life of the bag.

Send your message to us

Dust Collector Non woven Fiberglass Dust Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords