Polyester High performance Liquid needle felt filter bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

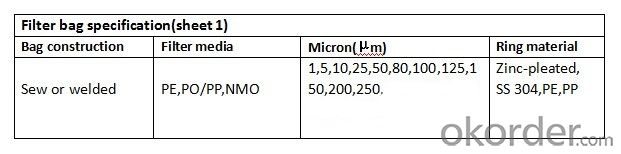

Polyester fibers( filter bag) are compressed and finishes are applied according to the process or application they are used for.All of the excellent characteristics of polyester apply to polyester felt, including good resistance to chemicals, abrasion and dry heat degradation, plus excellent dimensional stability

PP filter bag(Micron Polypropylene filter fabric) have a lower fiber release, more defined pore size and greater retention efficiency than other filter media(filter bag). Liquid PP filter bag offer high efficiency filtration and have a high solids catch capacity. MLD produce micron Polypropylene filter bags have their outside surface singed or glazed to prevent fabric fiber from the bag getting into the clean,filter process media. Micron PP filter bags are generally compatible with most fluids except those considered aromatic solvents or strongly alkaline.Liquid PP filter fabric(liquid PP filter bags) are recommended for prefiltering acids,aqueous and most solvent solutions.

- Q: Dust filter bag above the oil, how to clean up?

- The bag covered with oil to cleaning by high frequency vibration, dust collector will enter a larger dust particles in the wall of the bag all clear, and the influence of fiber will not tangle fastness, keep good bag, easy peeling of dirt. Chemical experiment: extraction bag samples, using professional equipment test dust filter oil composition, and thus the selection of washing raw materials to the maximum cleaning bag bag without causing any damage.

- Q: What does the filter bag filter? What's the principle?

- Some clothes get pilling easily, that is to filter the small ball

- Q: Do you have any special marks for Dafoe filter bags?,

- Nonsense, can not, and also spurt the code

- Q: The filter bag of washing machine is broken. Does it affect use?

- Does not affect the normal use, but some clothes on the debris and linter cannot be filtered out, it is best to find a silk stockings cut into the filter bag size re installed can be used normally.

- Q: Parameters of dust filter bag material

- The running resistance depends on the smooth degree of the filter medium surface, cleaning effect, general hope filter material with the same filtration efficiency, the greater the permeability is better, the resistance as low as possible, because it can save a lot of energy, in the use of air reverse blowing dust in the air under the same pressure, the same the air cleaning, the cleaning effect of breathable fabric bag do a large quantity of the small amount of air is better than the selection of fabrics.

- Q: Which house is the liquid filter bag good?

- The quality of liquid filter bags is good. Attention should be paid to the filter efficiency, pore size distribution, density, thickness, weight, air permeability, fracture strength and some other technical indicators.

- Q: How to choose the ear coffee bag?

- Hanging coffee and black coffee are different in content.The coffee bag is coffee.

- Q: How do you do if the filter bag is damaged in a large area?

- When the local bag is damaged, should stop all change (when the filter in the long-term work, fine dust accumulation in the filter layer permeability reduced, affect the system volume, although not damaged, it should stop all change), the best in the replacement of the bag precipitator suspend work at this time should be stopped ash cleaning controller is closed, open top manhole, and removable bag, when removed, the first bag cage out, then the spring ring of the upper opening of the cloth bag knead into a concave upward out of the bag, the bag in front of the new device, should be spent on clean dust clearing plate hole.

- Q: What are the use of polyester filter bags?

- Polyester filter bag use: petroleum chemical industry, automobile manufacturing, paint, paint, glue electronic technology, metal processing, water treatment, pharmaceutical and food and beverage and other low viscosity fluid filtration, has excellent filtering effect for various types of impurities.

- Q: What is the best way to use a filter bag?

- In order to better extend the use of filter bags, we should pay special attention to this aspect of knowledge at ordinary times. If we have different problems, we need to find a solution.First, the breakage of the bag. The shape of the filter bag and the installation method and mechanism of the filter bag determine the easily damaged position of the filter bag, so that the inspection and maintenance can be carried out.

Send your message to us

Polyester High performance Liquid needle felt filter bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 15000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords