Needle Punched Nonwoven Acrylic Dust Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Needle Punched Nonwoven Acrylic Dust Filter Bag

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton), Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Needle Punched Nonwoven Acrylic Dust Filter Bag

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Needle Punched Nonwoven Acrylic Dust Filter Bag

| HZ Filter | REF CODE: SY-500 | ||

| NAME: Acrylic filter felt | |||

| Fiber Material | Acrylic | ||

| Scrim Material | Acrylic staple yarn | ||

| Weight | GSM | 500 | |

| Thickness | MM | 2.1 | |

| Airpermeability | L/dm2/min | 120 | |

| Tensile strength | Warp | <=N | 600 |

| Weft | <=N | 1300 | |

| Break Elongation | Warp | <% | 30 |

| weft | <% | 30 | |

| Work Temp | Continuous | <°C | 140 |

| Peak | <°C | 160 | |

| Finishing | Heatset/carlender/singe /water+oil repellent/Film laminating available | ||

4. Application fields of Needle Punched Nonwoven Acrylic Dust Filter Bag

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

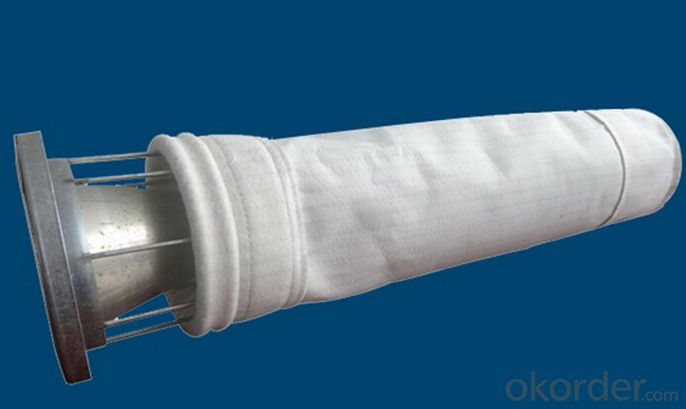

5. Images of Needle Punched Nonwoven Acrylic Dust Filter Bag

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: How to remove the filter bag of the drum washing machine?

- 1. Remove the water from the washing machine and use a screwdriver to press down through the square hole above the filter door.2, hold the plastic pipe plug, pull out the sewage flow, although and prepare a water container, water flow after the plastic pipe into the sewage flow, though. Restore the sewage pipe.3. Turn the filter bag counter clockwise.4. Clean with water.5, back in place, clockwise rotation can be.

- Q: How to clean the electrophoresis paint filter bag?

- Cleaning is very simple, just like washing clothes, the impurities inside out, rinse more than a few times. Solvent cleaning is better!! There is a high-pressure cleaning machine, not to mention

- Q: The filter bag in the washing machine is not available. Can I use it?

- Can be used, if you can buy, it is best to install, and if there are impurities in clothing, thread, etc., will twine the impeller, affecting motor rotation.

- Q: What is the filtration principle of high performance fiber filter bag?

- 1, the diameter of several hundred nanometers of fiber irregular accumulation structure, load on the traditional filter bag, you can filter bags of dust particles to achieve effective interception.

- Q: What is the dust removing filter material of the dust collector?

- Has good cleanup for PM2.5.Dust bag bag filter is running in the heart, the pulse bag usually cylindrical vertical dust hung in dusty gas from the inlet into the filter, through the guide plate of the hopper, the large particles of dust in the gas under the influence of the inertia force is isolated, directly into ash hopper.

- Q: I've seen a lot of posts about washing machines on the Internet. They all say it's OK to wear stockings. But how should I wear silk stockings? Do you have any skills or something?

- Washing machine filter is generally divided into two types: one is the bag type, one is inserted plate.1, you can observe the inserted plate of the filter screen, there is an arrow above, according to the arrow pointing position, there is hand press grip, you can get the filter screen, the installation can be directly fastened;

- Q: Dust filter bag how to maintain daily?

- Dust bag maintenance work is not to be ignored, this is the dust removal industry users are aware of matters needing attention. Because the performance of dust bag dust collector directly affects the use effect, it is important to dust bag maintenance work, performance and life can prolong the bag, so as to directly save maintenance and replacement cost of the bag. In a word, the dedusting effect is good, and the cost is saved, so that customers can gain great benefit.

- Q: How to choose the ear coffee bag?

- The freshly brewed coffee powder is packed into the filter bag and is black coffee without anything.1. Coffee is a drink made from baked beans.

- Q: What are the filter bags? Which ones are easier to use?

- According to the working conditions of the different filter materials, Tianlong users recommend the most suitable conditions for the most reasonable price, Tianlong products have been widely used in iron and steel, cement, environmental conditions of dust, chemical plants, waste incineration, road building, metallurgy, food processing, electronics, wood, finance, medicine and hospital ward, consulting room, bio pharmaceutical plant engineering, precision machinery, professional printing, electronic workshop, the central air-conditioning control room, cabinet room dedicated air-conditioning industry in product quality, well received by users, regional sales throughout the country.

- Q: What's wrong with the filter bag in the washing machine?

- If you can not buy it myself, with a scarf like cloth sewn into the ring to pressure, but the relatively short life span, easy to wear, no original strong ah

Send your message to us

Needle Punched Nonwoven Acrylic Dust Filter Bag

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 200000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords