Industrial Nonwoven water proof Polyester Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

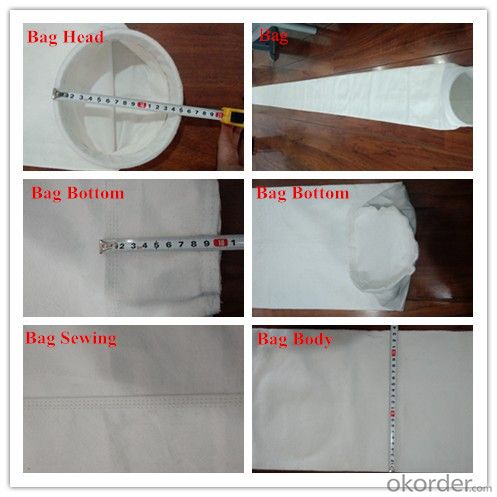

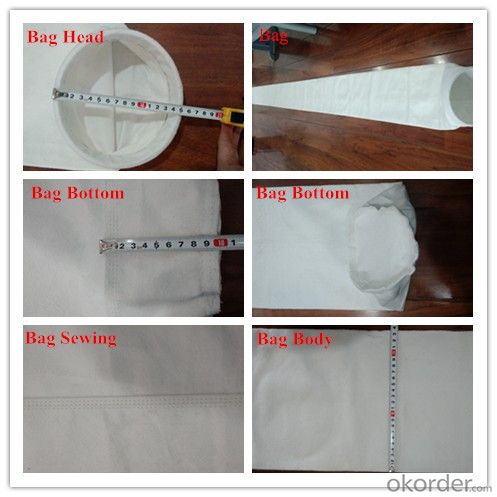

Specification

Specifications:

Compositions | polyester fiber | |

Weight (g/ m2) | 500 | |

Thickness (mm) | 1.8 | |

Air permeability (L/m2/s) | 150-300 | |

Tensile strength | 1200 | 1250 |

1300 | 1350 | |

Tensile Elongation(%) | <20< span=""> | <30< span=""> |

<45< span=""> | <30< span=""> | |

Broken strength | 2.40 | |

Continuous working temperature(°C/°F) | 140/284 | |

Short time Working temperature(°C/°F) | 160/320 | |

Anti-acid | Excellent | |

Anti-alkali | Excellent | |

Anti-abrasion | Excellent | |

The stability of water solution | good | |

Finishing treatment | Singeing, calendaring, plain, Heat Set | |

Top load/ entry(walk-in plenum) | Snap Band | |

Bottom load/ entry(common in bin vents) | Disk With Wear Strip | |

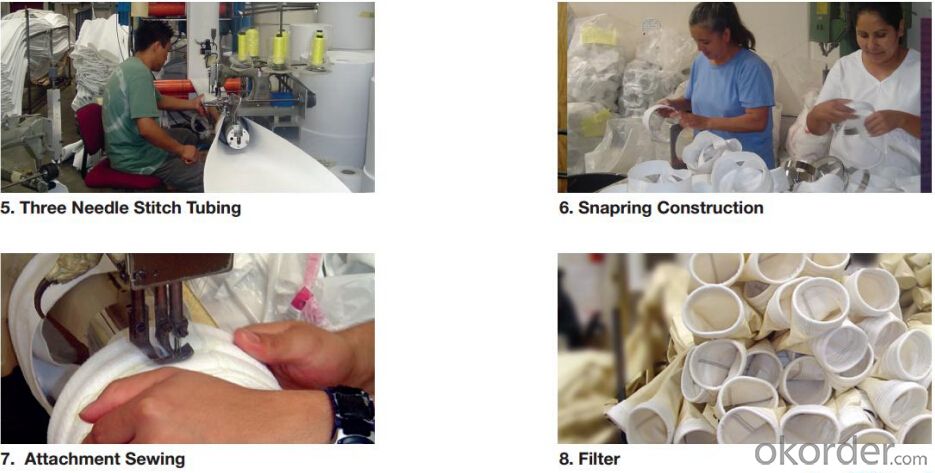

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Packaging & Shipping

Company Information

- Q: How can the washing machine's filter bag be clean?

- In general, the filter bag of the washing machine can be removed, please read the instructions carefully, even if it is not easy to tear open come down to, as long as don't have much stuff, generally does not affect the quality of washing.

- Q: What are the benefits of using a filter bag

- Secondly, the filter bag is made of advanced technology, it is not the phenomenon of the needle eye and it is very good.

- Q: How do you clean a filter bag with oil stains?

- Clear the dust filter bag with oil: using high frequency vibration, will enter the dust filter bag inside the wall of the larger dust particles removed, will not affect fiber entanglement of fastness, keep the filter bag is good, easy tear of dirt. Chemical experiment treatment: extract the bag samples, using the professional instrument laboratory detection filter filter bag oil composition, to adapt to washing raw materials, the maximum cleaning filter bag and without causing any damage to the filter bag.

- Q: What is the filter principle of the high performance filter bag?

- The network structure of nanofibers can reduce the thickness and line density of the supporting filter, thus reducing the pressure loss and improving the efficiency of production.

- Q: What is the quality inspection of the filter bag?

- The instrument is used to test the filter bag after cleaning, to ensure the quality of cleaning is met. Through the processing of the above process, the cleaning bag can meet the requirement

- Q: What is the advantage of the oil filter bag?

- In addition to oil filtering bags: Multi-layer melt polypropylene filtration material, which helps to filter liquid level by stage

- Q: How can you not damage the filter bag when the filter bag is installed?

- The bag cage should be inspected before the bag cage is installed. No burrs, soldering, welding and deformation are not allowed. After the bag is inserted into the filter bag, the bag should be slowly devolution, the speed of devolution will be cut and the filter bag will not be free fall.

- Q: What is the cleaning method of the filter bag

- So that's how you clean the filter bag. Have you learned it? One thing you need to be aware of is that you have to choose the quality of the filter, so the filter will be good. In order to select a quality filter, you must go to the hui long filter purification co., LTD. Huilong filtration purification co., LTD. Is a company that "relies on science and technology to revitalize the famous nationality industry, and make a world brand" Culture and "customer first, win-win cooperation". We are always committed to the continuous development of the filter business, continuous development, innovation and progress. Pursue the peak of technology. Create a world class filter "carrier" filter

- Q: Who has used a liquid filter bag? What is its feature?

- The dimension stability is good, the fiberglass itself does not contract at the standard temperature Chemical etch is good, acid and alkali resistance.

- Q: What are the features and methods of using filter bags?

- The durable filtration bag is made of pure, high quality and high quality blown ultrathin fiber filter. Filter bag has excellent chemical stability and heat resistance performance, is applied to the highest in the performance of the filter material industry representatives, is all common varieties of filter material in the top performance.

Send your message to us

Industrial Nonwoven water proof Polyester Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches