Fiberglass Cement Dust Collector Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Fiberglass Cement Dust Collector Filter Bag

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Fiberglass Cement Dust Collector Filter Bag

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Fiberglass Cement Dust Collector Filter Bag

Technical Parameters | ||

Item | Parameters | |

Product Name | Glass Fiber Compound | |

Weight | 850±5% g/m² | |

Thickness | 3.5±10% mm | |

Air Permeability | 8-15 m³/m²/min | |

Breaking Strength | Warp | >1800 N/50*200mm |

Weft | >1800 N/50*200mm | |

Breaking Elongation | Warp | << span="">10 % |

Weft | << span="">10 % | |

Working Temperature | Continuous | 220 ℃ |

Instant | 260 ℃ | |

Finish Treatment | Singeing Calendering Laminating Oil&Water Repellent | |

4. Application fields of Fiberglass Cement Dust Collector Filter Bag

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

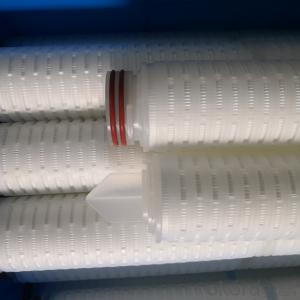

5. Images of Non Fiberglass Cement Dust Collector Filter Bag

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: What is the reason for the strong drop in the broken filter bag of the cement mill dust filter bag

- Jam. The main reasons for the failure of bag filter bag are: The oil is in a jam. Oil mist blockage mainly boiler start-up and low load operation for oil fuel, not the filter bag protection or protection does not reach the designated position, this will lead to the residual resistance increase of filter bag, even the powerful soot cleaning is difficult to solve this problem. Dust jam. In the process of filter bag dust collector of fine dust can enter into layers of filter bag, but when the ash removal is not possible to these all back into the inside of the filter bag dust filter bag outside, so after years of running the residual resistance of filter bag will continue to increase, in addition low boiler load for a long time when the filter is not clear ash can also lead to the emergence of the problem.

- Q: The filter bag in the washing machine is broken. How do you fix it

- Look for a professional after sale personnel to check to be able, usually have guarantee service.

- Q: How do you pack the filter bags in the washing machine

- One hand holds the middle position in the net and the other hand is pressed from the lower pressure, which can be removed and must be careful not to break the card.

- Q: Problem with the washing machine filter bag

- You see if the filter is blocked, or the hole in the inner drum is blocked

- Q: How do you use a filter bag?

- Third, the cloth should not hang too loosely or too tightly, too easily to accumulate dust, too close to pull out. Fourth, new process old filter bag should not be mixed, avoid damage time different effect equipment normal work

- Q: How many types of filters are in the filter bag?

- Flat: the filter bag is flat, including rectangle and trapezoid, which is represented by the perimeter of the length.

- Q: Does the water in the tank always relate to the washing bag

- Don't wash so often, wash once in a dozen days with the urn, after a few days water is good.

- Q: What is the filter bag for the washing machine?

- We always see something fluffy in our clothes when we wear clothes, and the washing machine filters the stuff!

- Q: Who has used a liquid filter bag? What is its feature?

- The filtration efficiency is high, can reach more than 99.5% Expanding filter cloth (bag), improving filter wind speed and filtration efficiency, reducing the volume of dust removal equipment

- Q: What is the filter bag made of foam tea?

- That you go to the big supermarket will have to sell, there are two kinds, one kind is spun yarn bags, such as gauze, one is made of paper, paper bags are cheap and convenient, spun yarn is used for many times, see what you need...

Send your message to us

Fiberglass Cement Dust Collector Filter Bag

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords