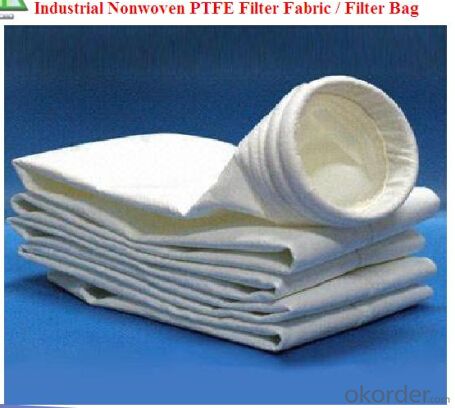

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Specifications:

The PTFE needled felt is a fiber of extremely stable chemical performance

1,Continuous operating temperatures above 250℃, the instantaneous temperature of 280 ℃.

2, Good acid & alkali resistance and oxidation resistance, non-combustible.

3, The only not aging fiber.

4, Can be used under the most adverse conditions, with extremely long service life, and usually the service life is 4 years.

specification

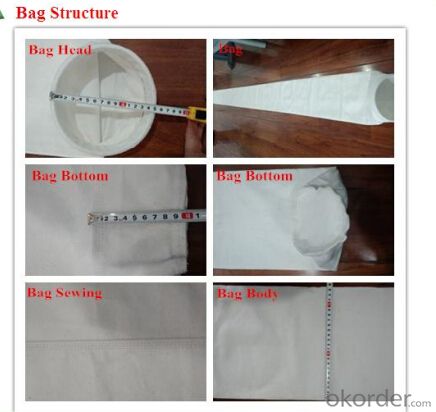

Description of product | TF/TF1750-W |

Fiber | 100%PTFE |

Substrates | 100%PTFE |

Square weight | 750g/m2 |

Thickness | 1.1mm |

Density | 0.68g/cm3 |

Air permeability | 90L/dm2.min |

Breaking Strength-lengthways | ≥450 N/125px |

Breaking Strength-crosswise | ≥450 N/125px |

elongation@200N/125px-lengthways | <5% |

elongation@200N/125px-crosswise | <5% |

Heat shrinkage@150degC,90min | 2% |

Bursting strength | >300 N/cm2 |

Continuous temperature | 260℃ |

Instantaneous temperature | 280℃ |

Post-processing | Heat-setting |

Heat Setting

Basically all needle felts at Shandong Aobo are heat-set.

The residual shrinkage is reduced to a minimum by means of an optimum combination of the decisive quality factors , such as temperature, dwell time and cooling phase.

The controlled process management during the cooling phase ensures that the filter bags will have excellent form stability even under most difficult conditions.

Quality-determining parameters

Temperature

Reaction time

Cooling time

Thermal surface treatment

The surface of any needle felt influences the structure of the filter cake, its cleanability as well as pressure drop and the emission.

- Singed

Three different kinds of treatment are possible:

smooth for adhesive and moist dust

medium for universal treatments

rough low agglomeration or fine dust

- Calendering

Through calendering a more compact fiber structure is achieved. This allows a more surface-active separation of dust with lower emission.

Protective Impregnation

- hydrophobic, oleophobic

This treatment makes it more difficult for moisture to penetrate into the needle felt. Thus the risk of excessive dust deposits and caking is reduced.

- Protection against acids and hydrolysis

Special impregnation based on TEFLON®. This treatment coats the fiber surface, thus providing it with the anti-adhesive character of a PTFE finish.

An oil- and water-repelling effect is produced, and the fibers are effectively protected against acid and hydrolysis attack.

- Active finish, hydrophobic

Special water-repellent treatment providing a high cleaning and separation efficiency.

Coatings

Through the filter-active coating dust is already separated on the surface. In addition the anti-adhesive surface reduces the adhesive forces between the filter medium and dust cake.

Advantages

Optimised cleaning

Increased service life

High separation efficiency

PTFE-Coating, hydrophobic and oleophobic fibers, protection against acids and hydrolysis

Primary finish membrane, microporous foam coating, high separation efficiency, easy dust release, hydrophobic and oleophobic

Packaging & Shipping

Company Information

- Q: How do you clean a filter bag with oil stains?

- Filter bag with oil can drug soak: choose the appropriate chemicals soak filter bag, the grease dirt removal within the filter bag aperture, maximum limit increased the permeability of filter bag. Clean: choose the appropriate washing materials and strict proportion. Low temperature water cleaning, the water is uniform, the strength is moderate, no mechanical damage to the filter bag. Drying: the heat air drying is about 110 degrees centigrade, the stability of the filter bag is kept, and the filter bag is not deformed after drying.

- Q: What are the advantages of fiberglass filter bags

- The bag filter is a type of dry filter. It is suitable for small, dry, non-fibrous dust. Filter bag used textile filter cloth or non textile mat is made, using the fabric filter effect of dust filters, gas when dusty gas into the bag filter, large particles, major dust, due to the effect of gravity settling down, fall into the hopper, contains the fine dust of gas through the filter material, the dust were blocked, the purified gas. The dust removal efficiency of the new filter is not high enough. Filter material to use after a period of time, due to the screen, collision, stranding, diffusion, electrostatic effect, such as a layer of dust accumulation on the surface of filter bag, at the beginning of the dust layer is called layer, after the movement process, early become the main filter to filter material layer, depending on the role of the first layer, large mesh filter material can also get higher filtration efficiency. As in the accumulation of dust on the surface of the filter material, filter efficiency and resistance are corresponding increase, when the pressure difference on both sides of the filter material is very big, can put some tiny dust particles are attached to the filter material has been squeezed in the past, the dust collector efficiency decline. In addition, the high resistance of the dust collector will cause the dust removal system to decrease significantly. Therefore, when the resistance of the dust collector reaches a certain number, the dust should be cleared in time. Do not destroy the initial layer when clearing ash, lest the efficiency decline.

- Q: Choose what aspects to consider when choosing a filter bag

- Dust and dust are collected in the outer surface of the filter, while the clean gas is filtered through the filter. The inside of the filter bag is used to support the filter bag to prevent the bag from collapsing, and it helps to clear and redistribute the dust cake.

- Q: How many types of filters are in the filter bag?

- Alien: shape specific filter bag, whose specification is represented by the characteristic parameters of its construction.

- Q: Does the water in the tank always relate to the washing bag

- It could be fiber in the filter bag.I hope my answer will help you.

- Q: How can you not damage the filter bag when the filter bag is installed?

- The dust filter bag has a great effect on the dust removal effect, and the filter bag must not be damaged by the installation. 1 should pack the filter bags to the installation location and install one of them. The filter bag cannot be dragged carelessly on the board, to prevent the metal burrs from the surface of the filter bag, and damage the filter bag. Remove from the packing box until it is installed to the orifice of the flower plate, not touching any metal or surface roughness. Use the protective cover provided by the supplier when using the orifice, in case the filter is touching the plate hole.

- Q: How to unload the washing machine's filter bag?

- The fixed device of a filter bag may be three clasps, and the hard drag is not coming, and you try to use a zig-zag screwdriver to pry into the lock.

- Q: How do you check the filter material of the filter bag?

- Filter bag dust filter core, its quality directly reaction precipitator dust removal efficiency and service life, in order to ensure the quality of filter bag, cope with the production of filter bag filter material for sampling, determine its performance up to standard. The filter material needs to be tested and tested: 1, the appearance of filter material: observe whether there is a jumper line, defect, puncture, black spot, joint, broken line, etc. 2, the mechanical properties of the filter material: testing the tensile strength, elongation at break of filter material, warp/weft direction of the load elongation and burst strength of filter bag is in line with the standard.

- Q: How is the filter material processed by the filter bag?

- The second is heat finalization to ensure the stability of the chemical fiber filter, to maintain the reliable work of the dust collector, and to deal with the heat finalization of the filter material. It is also that hot melt pressure processing can increase the density of the needle felt, make the surface pore smaller, the fuzz is hot, smooth and smooth

- Q: How to buy the paint filter bag in the car painting

- Car paint German parrot paint, of course, you ready to buy on taobao, I will buy, there is very good on taobao input car paint parrot came out. It's in shenzhen. The cleaning machine has extensive application in the area of industrial cleaning, and the car factory should also prepare several, wash the machine wash the paint, the welding slag effect... It is recommended that you use the chengdu lifeng cleaning machine, and the cleaning machine should not only look at the management and maintenance of the latter, but also choose a good brand. The coating site is polluted, such as the floor of the lacquer room is not clean and clean. Poor equipment, no positive pressure in the baking room, filter net... The process of determining the relationship between paint and car color is determined by graphical method. The color is determined only in the car itself...

Send your message to us

Industrial Nonwoven PTFE Filter Fabric Filter Bag

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches