Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

There are kinds filter materials available, such as Polyester(PET), PP(Polypropylene), PA(Polyamide), Nomex(Aramid), PPS(Ryton),?Polyimide(P84), Acrylic Filter Bags, Fiberglass, PTFE, etc.

Lower the intension and requirement of management and maintenance, our company researches and develops the pulse bag filter of MD series, which is the ideal equipment used for dust control in the fields of construction material, chemical industry, coal etc.

2. Features of Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

dust filter

1. the material is Fiberglass

2. It has excellent resistance to acid and alkali corrosion resistance

3. Working temperature : 240°C-260°C

4 . Hydrolysis resistance performance is good

3. Specifications of Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

Technical Parameters | ||

Item | Parameters | |

Product Name | Glass Fiber Compound | |

Weight | 850±5% g/m² | |

Thickness | 3.5±10% mm | |

Air Permeability | 8-15 m³/m²/min | |

Breaking Strength | Warp | >1800 N/50*200mm |

Weft | >1800 N/50*200mm | |

Breaking Elongation | Warp | << span="">10 % |

Weft | << span="">10 % | |

Working Temperature | Continuous | 220 ℃ |

Instant | 260 ℃ | |

Finish Treatment | Singeing Calendering Laminating Oil&Water Repellent | |

4. Application fields of Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

1) The fume and smoke treatment and particle removing system in metallurgy plant, alloy plant, steel works, moulding factories, fire-retardant factories and power stations

2) Fume filtration, tiny particle recycle and division of liquid and solid in aluminum electro analysis, tin, zinc, cooper and other rare metals

3) Smoke filtration in garbage burning, coal-feed boiler and liquidized laid boilers

4) Division of liquid, solid and tiny particle recycle in chemicals, coke, carbon, dyestuff, pharmacy and plastics

5) Asphalt concrete mixture, cements, ceramics, building materials, lime and plaster

6) Dust treatment, purification and collection in electronics, mining, foodstuff processing, flour and timber processing.

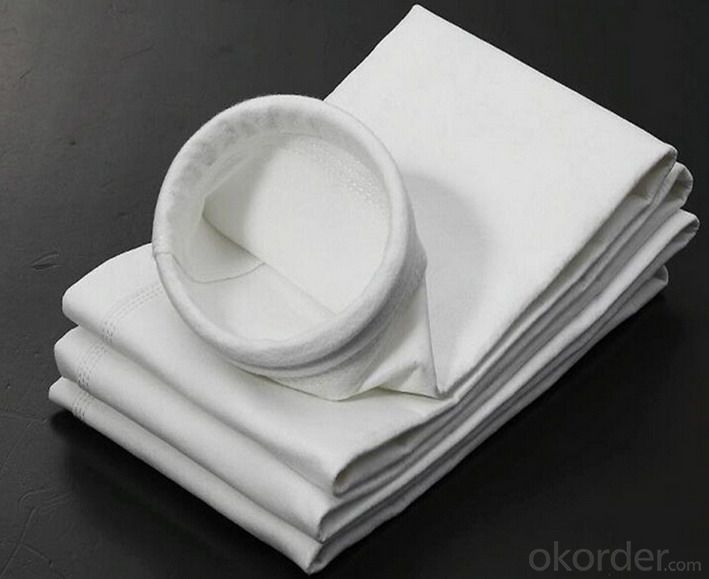

5. Images of Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

6. FAQ

1) Are free samples available?

Yes. But express delivery cost is to be collected and we will pay it back after confirming the order.

2) What about the lead time for mass production?

Honestly, it depends on the order quantity and the season you place the order. Generally speaking, we suggest that you start inquiry two months before the date you would like to

get the products at your country.

3) What is your terms of delivery?

We accept EXW, FOB, CIF, etc. You can choose the one which is the most convenient or cost effective for you.

- Q: In what aspects is it convenient to choose the filter bag?

- First, it is important to understand the temperature of the smoke that is being processed. If the normal temperature of the filter is lower than the temperature of the flue gas, it is possible to cause the cloth bag to burn down and cause a large economic loss. So how do you select the filter by the smoke temperature? Filter material by using temperature is divided into: under normal temperature is below 130 ℃, the temperature filter material of 130 ~ 180 ℃, high temperature filter material of 180 ~ 280 ℃. It is known that the temperature of the flue gas and the temperature of the filter can be selected by the filter. The second step is to understand the composition of smoke: this includes the content of the dust, the proportion, the size of the particle size, the viscosity and the moisture content of the flue. The method of cleaning the dust dust, the method of reprocessing and the filter wind speed of the filter were obtained. Usually a large amount of dust and dust is sticky and light condition choose pulse bag filter, filtration speed most control over 1.2 m/min, the minority under 1 m/min. The third step is to understand the amount of smoke that needs to be processed: the amount of air that dust can be treated by the dust collector is usually the operating air volume and the system leakage coefficient (10% ~ 15%). The formula: S = Q / 60V gives the total filter area by the formula: S = Q / 60V. S: total filter area Q: system processing air volume V: filter wind speed.

- Q: What are the benefits of using a filter bag

- Because of the people environmental protection consciousness enhancement, the filter bag also gradually has been widely used, in some rooms, hospitals, laboratories and other places will use the filter bag, filter bag even have good use in air conditioning, so, the filter bag used so widely, filter bag exactly what are the benefits?First of all, from the manufacturing of filter bag, filter bag is adopted industrial sewing production way, there is no silicone oil pollution when using, is especially health.

- Q: Filtration efficiency of liquid filtration bag

- Different companies have different test methods and efficiency requirements of filter bag accuracy, some are defined as 80 ~ 85%, some are defined as 50 ~ 70%.

- Q: How to choose a liquid filter bag

- Filter bag precision options: This is the most troubling question. For example, to remove visible particles, use a 20 or 25 micron filter bag. To remove the cloud from the liquid, use a 1 or 5 micron filter bag. To filter out the smallest bacteria, you need a 0.2 micron filter bag. The problem is that there are two types of filter units: absolute accuracy/nominal accuracy.

- Q: How does the filter bag work?

- Mechanical vibration wave sootblower is often used in small single cartridge filter, it is the use of filter plate produced by the eccentric gear on shaking power to clear the ash, this action need downtime after operation.

- Q: What is the cleaning method of the filter bag

- So that's how you clean the filter bag. Have you learned it? One thing you need to be aware of is that you have to choose the quality of the filter, so the filter will be good. In order to select a quality filter, you must go to the hui long filter purification co., LTD. Huilong filtration purification co., LTD. Is a company that "relies on science and technology to revitalize the famous nationality industry, and make a world brand" Culture and "customer first, win-win cooperation". We are always committed to the continuous development of the filter business, continuous development, innovation and progress. Pursue the peak of technology. Create a world class filter "carrier" filter

- Q: How can the filter bag be processed later?

- Waterproof and anti-oil treatment Of needled felt filter material using fluorocarbon resin and PTFE impregnated processing oil waterproof processing, the wet dust gas dust (especially for water imbibition, deliquescence) the surface of the filter bag dust catcher, more easily to avoid and reduce the paste bag

- Q: How do you check the filter material of the filter bag?

- Filter bag dust filter core, its quality directly reaction precipitator dust removal efficiency and service life, in order to ensure the quality of filter bag, cope with the production of filter bag filter material for sampling, determine its performance up to standard. The filter material needs to be tested and tested: 1, the appearance of filter material: observe whether there is a jumper line, defect, puncture, black spot, joint, broken line, etc. 2, the mechanical properties of the filter material: testing the tensile strength, elongation at break of filter material, warp/weft direction of the load elongation and burst strength of filter bag is in line with the standard.

- Q: How is the filter material processed by the filter bag?

- Finally is chemical treatment to improve the filter material, especially the dust filtering performance and the strength of glass fiber filter material, heat resistant, flame retardant, corrosion resistant performance, are of great significance.

- Q: How to buy the paint filter bag in the car painting

- Haha, it's easier for me. I want to answer the question from all the processes in the painting workshop. Pre-treatment, electrophoresis line need the following filtering material: 1, the filter bag (need) in the tub filter 2, phosphate slag filter bag/belt (need to use phosphate slag filtration system) 3, biofilm generated electrophoresis (ultra filtration membrane filtrate need) coating,... Core masterbatch 1 degreasing powder, powder formula: degreasing powder core masterbatch + base (either soda ash, sodium bicarbonate, sodium silicate) 2, alkaline water recipe: degreasing powder core super universal masterbatch + surfactant + + water + preservatives + essence 3 wire drawing powder, water-based neutral formula: super nanometer emulsifier + super oil emulsifier, wire drawing powder + water + preservatives, fragrance 4, preparation of alkaline...

Send your message to us

Dust Bag Fiberglass Filter Dust Filter Bag Dust Collector

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 500000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords