PVC Light Weight Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Light Weight Conveyor Belt for Food Industry

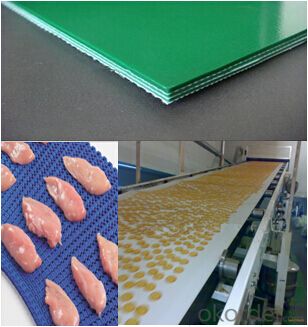

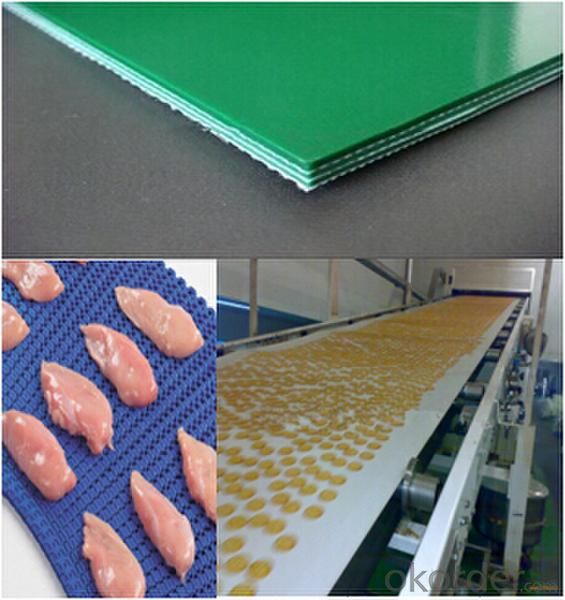

Description of PVC Food Conveyor Belt:

Food conveyor belt choose high quality high strength polyester fabric as the core, good flexibity, using environmental PU and PVC as the material of conveyor belt, one of them, the PU belt not only have common character of conveyor belt hight tensile stength, light, thin, but also oil-resistant, abrasion-resistant, non-toxic.The above could meet the food grade standards,and could contact with food,no peculiar smell.

Characteristics of PVC Food Conveyor Belt

It adopt high-intensity polyester filament and yarn weave as the whole core, and then is impregnated by the PVC. Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Cover thickness can be from 0.5 to 4 mm.

Features of PVC Food Conveyor Belt

Non-conductive

Anti-static

FDA and HACCP standards

Resistant to fats, chemicals, oil fat and abrasion

Dimensional stability

Less noise

Various surfaces with high, medium, and low coefficient friction

Special belts can also be manufactured complete with

1) Guides, profiles and sidewalls fitted by means of high frequency or hot air welding machines.

2)Curved or Corner conveyor belts it allows the solving of logistic problems through the deviation of the conveying system from a few degrees to a 180°C turn.

3)Belts can be made endless, spliced or with prepared ends for on-site splicing to be done with dedicated Adhesives.

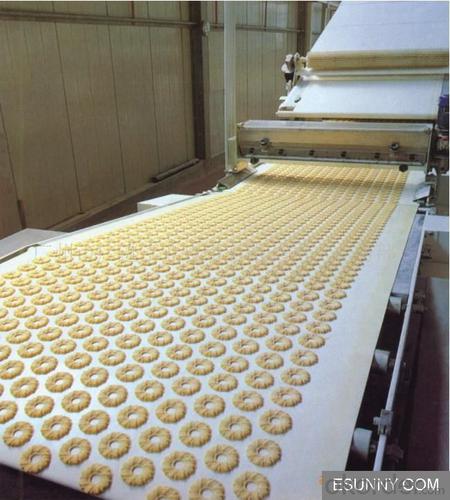

Photo of PVC Conveyor Belt:

If you want to find more details about the pvc food conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q: What problems need to pay attention to when inflating the pipe?

- The charging pressure does not exceed the working pressure of the air sac, and the sharp object is prevented from scratching the gasbag during the inflating process

- Q: In addition to the smell of rubber?

- Activated carbon adsorption method of activated carbon is internationally recognized drug experts, activated carbon masks, gas masks are activated carbon. This product uses the physical function of activated carbon, deodorization, detoxification, without any chemical additives, no impact on the human body. Each house from two to three dishes, 72 hours can basically eliminate indoor odor. This method can also be used in combination with other chemical methods, and comprehensive treatment is better.

- Q: How to test the abrasion resistance of rubber?

- Rubber: the word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process. The finished product is material with elasticity, insulation, waterproof and air.

- Q: How to identify the tire rubber is raw or cooked

- All use glue tire manufacturing, rubber is the parent material of rubber products, rarely used directly.

- Q: What is rubber leather?

- Rubber (Rubber): highly elastic polymeric material with reversible deformation. It is elastic at room temperature and can produce great deformation under very little external force. It can be restored to original state after removing external force. Rubber is completely amorphous polymer, its glass transition temperature (T, g) is low, the molecular weight is often large, more than hundreds of thousands.

- Q: What is food grade natural rubber?

- Is mainly made of natural rubber, made of natural rubber products, through the relevant national food contact using rubber testing standards, to reach the food grade.

- Q: I do rubber products, I would like to ask what metal accessories are rubber products, the specific name is what, good, then points

- High pressure rubber tube, natural rubber tube, Shandong rubber tube, high pressure rubber tube, low pressure rubber tube, Ding Qing rubber tube, high quality rubber tube;

- Q: What are the bridge rubber air bags used for?

- Open the valve, inflated to the specified pressure, you can close the valve, must not exceed the pressure.

- Q: How to distinguish between plastic products and rubber products, toys?

- There are several ways to distinguish between plastic and rubber products:1, color: plastic products, relatively transparent color, relatively strong, and rubber products are relatively poor transparency;2, thickness: plastic product thickness than rubber products thin;3 hardness: general plastic products than rubber products slightly hard;4: texture: plastic products are more smooth or microstrip lines, and rubber products on the surface of some of the same as human skin, texture deeper or more rough;5, taste: plastic taste, the taste of micro strip plastic, and rubber products are micro rubber rubber flavor;6, weight: general plastic products will be slightly lighter than rubber products.

- Q: What is the harm of rubber to the human body?

- Depends on what rubber, and see what the rubber does. Some rubber additives used more, the processing of the flavor is more heavy, more toxic. If you do containers, try not to use it to store people's food, so as not to volatilize, causing harmful substances volatilization.Guidance opinion:Some of the rubber itself is no poison, and basically additive little, there will be no toxicity. Such as silicone rubber, but also can do food grade, used in tableware, artificial organs and so on.Rubber has a component called aniline, which contains a special odor.Harm: 1, blood damage, 2, liver damage, 3, urinary system damage, 4, nervous system damage, 5, skin damage and sensitization, skin itching, 6, crystal damage, 7 carcinogenic, teratogenic.Measures: keep the air circulation in the work place; the adsorption of poisonous gas; do personal protection; strengthen the monitoring of toxic and harmful substances in the workplaces; strengthen the occupational examination.May wear the gas mask, has certain function.

Send your message to us

PVC Light Weight Conveyor Belt for Food Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords