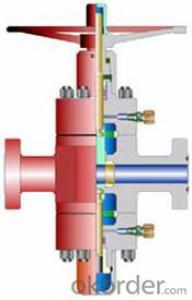

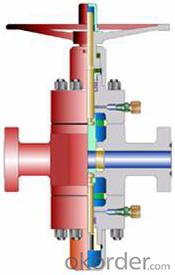

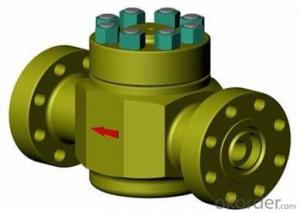

Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | China (Mainland) | Model Number: | Hydraulic plate valve | Brand Name: | sehm |

| Type: | Rotary Drilling Rig | Certification: | API | Usage: | Oil Well |

| Condition: | New | Warranty: | 1 | Voltage: | 2,000-15000 psi |

Specifications

Hydraulic plate valve

SS Gate Valve Handwheel Operated

1.Medium: water, oil, gas.

2.Certificate:API 6D,TS,CE.

Hydraulic plate valve

Applicable standards:Steel gate valves, API 600 / API 6D

Steel gate valves, ISO 10434 / ISO 14313

Steel valves, ASME B16.34

Face to face, ASME B16.10

Flanges end, ASME B16.5

Buttwelding ends, ASME B16.25

Inspection and test, API 598 / API 6D

Design description:

Full port design

OS&y,outside screw and yoke

BB,Bolted bonnet

Flexible wedge,fully guided

Choice of solid or split wedge

Renewable seat rings

Forged T-head Stem

Rising stem and non-rising handwheel

Flanged or buttwelding ends

Available with BG operator

Gate Valve Product Details

Design and Manufacture | ANSI B16.34,API600,API603,BS1414 |

Face to face(end to end) | ANSI B16.10,API6D |

Flanged connection | 2"~24" TO ANSIB16.5,22",26"~36" TO MSS-SP-44 to API 605 on Request |

Test and inspection | API 598,API6D |

Butt welded end | ANSI B16.5 |

A. Anti-friction ball thrust bearing: Reduces friction between mating parts to ensure smooth operation

B. Grub screw: Secures yoke nut in the bonnet

C. Grease nipple: Supplies lubricant to the mating parts

Manufacturing Process

STANDAR3DISATION

All products are manufactured in accordance with the guidelines of International Standard accepted all over the world such as Manufacturers Standardisation Society (MSS), American Petroleum Institute (API), American Society of Mechanical Engineers (ASME), British Standard (BS), Bureau of Indian Standard (BIS).

PROCURMENT OF RAW MATERIAL

In the manufacturing process we require Castings of different grades, Stainless steel Bars, forgings, hardware, gaskets & paints. All raw material purchase from the reputed & genuine concerned supplier.

QUALITY CONTROL

All raw materials are checked by our Quality Assurance Department prior to manufacturing process. For an example, when we received the castings, it is checked visually and dimensionally for machining tolerance. We also check the foundry chemical Test Certificate and physical test certificate, compared to suitable international standard and passed to machining shop for the further process, if it is rejected it is send back to the supplier.

MACHINING

The raw material issued to the machine shop for the machining, is machined strictly as per the relevant drawings.

INPROCESS TESTING

If it is found OK dimensionally the valve body and bonnet are sent for the hydro testing. All internal parts such as seat, disc, stem are measured by the Vernier Caliper or micrometer, if it is found O K than pass to assembly section for the further assembly. All the valve body and bonnet are tested on the motorized pump or hand pump as per the relevant standard. The theory being, when the body or the bonnet is under pressure there should not be any leakage or drops of the testing fluid from any portion of the castings. If any leakage observed, it is rejected and sent back to the foundries.

ASSEMBLY

The body and bonnet, which are Hydrostatically O K, are sent to assembly section, duly handled with care to avoid the scratches on the machined surfaces. In the assembly section body and bonnet are drilled on drill machine with the help of jigs & fixtures for uniformity and interchangeability.

LAPPING

In metal to metal seated valves, seat & disc/plug are lapped by Rough Lapping Paste to smoothen the seating surface and than lapped with very fine grade lapping paste for the proper sealing of disc & seat surface, to ensure zero leakage.

TESTING

After assembly of new complete valve is sent for Hydrostatic Testing. If no leakage is found as per the relevant standard, it is sent to finishing section.

FINISING/PAINTING & PACKING

The valve body and bonnet is debarred and finished by flexible shaft grinders for better appearance. One coat of corrosion resistance primer (red oxide) is sprayed, and colored as per the codes, twice for superior surface look.

Valves are packed either in wooden boxes or Gunny bags duly protected by ends enclosures and soft material to avoid any damages during transit.

MainFeatures :

Body & Bonnet made from high quality casting with liberal sections. The castings are precision machined for high performance

Bi-Directional Shut-Off

Die moulded Graphite (Grafoil) Packing Rings, controlled clearance between stem, gland and bonnet bushing for guaranteed low emissions and also suitable for higher temperature.

Deep stuffing box is providing for tightness and maximum long packing life.

Swinging Eye Bolts facilitate easy access to the stuffing box.

Back seating feature facilitates repacking of the stuffing box on line with the valve in fully open position.

Seat Ring Screwed in to the body are replaceable type. Seal welded type Seat Ring & Integral Seat cab also be offered on special request.

Stellited Disc, Seat Ring & Back Seat can also be offered on special request.

Higher Pressure & Higher Size Valves are provided with Thrust Bearings and also with Gear drive arrangements.

In built wear life for long duration of service.

- Q: I have a 1989 Jeep Cherokee with 218,700 miles on it and my engine has thick oily gunk on it, possibly from a leaky valve cover gasket, should I change the gasket? I have been told that this is normal and not to worry about, but from the amount of this gunk, I find it hard to believe this is normal. The top of the valve cover has a light covering of gunk, but on the sides and towards the bottom of the engine. it gets very thick and at some places you can't even make out whats suppose there. Does a leaky valve cover gasket mean that there is another problem going on?Can leaving the oily gunk on the engine cause any problems?Any info would be greatly appreciated.

- Not to be mean but you can't work on what you can't see! Take the Jeep to a wand type car wash with a bag of quarters. Lift the hood and spend some time with high pressure soap and clean the entire engine and under-hood compartment. Don't bother covering anything. Leaking valve covers don't mean anything is wrong, it just makes a nasty mess. Remove valve cover/s and scrape old gasket material of the head/s and cover/s. The best valve covers in the world won't seal until the valve cover/s are completely flat. *This is an age old problem with stamped steel covers. If you want to get extra slick, chase down some aluminum cover/s. There stiffer and less apt to leak when you snug them back down. I'll let you in on a racers secret to make them seal. Buy a tube of Dow Corning or Permetex clear RTV silicone sealer. Scrape down the valve cover gasket surface till it's clean. Wipe the gasket surface down with CRC Brake Clean. Run a bead of the clear RTV on the valve cover and let it set-up for at least five minutes. Lay a Fel-Pro - Blue Stripe valve cover gasket on the valve cover. Seat it with your thumbs. Scrape-down the cylinder head where the gasket goes till it's perfectly clean. Clean the gasket seating surface on the cylinder head with C5RC Brake Clean. Lay a small bead of the RTV on the outside of the gasket which will meat the cylinder-head. Carefully set the cover on the head and gently alternately tighten them. It's OK to drive the vehicle as soon as you're done!

- Q: My chevy s-10 pickup automatic is shifting rough from 1st to 2nd, gives the truck a bump when shifts. Tech says I likely need a valve body replacement. He also indicated I could drive this for a while if I wanted. What more can happen if I prolong replacement? Truck is still at a fair blue book value and I'm wondering if I should sell it now. I have been very lucky in not having to sink any $ aside from normal wear and tear into it, so for me to have it replaced is the first $ investment. I have 103k miles for 2000. Anyone else in a sim sitch, or having multiple problems at this mileage as well? I'm wondering if this is the begininng of the end?

- How much do you think you'll sell a truck with a failing transmission for? Or, are you going to hide the problem from the buyer? Flush it again, and spring for synthetic this time.

- Q: 1999 Mercury Cougar in awesome shape no engine problems, and has just under 86000 miles. I bought it recently and the check engine light came on out of nowhere and I realized It was an EGR issue the code was p0401 insufficient flow. I had a mechanic replace the solenoid valve as well as clean all of the carbon gunk off the valve and the light was off, then suddenly POPPED back on, making me really nervous and kind of upset. So today I had a few errands to run and I said I wasn't going to go get it read again until tomorrow, and it just Went off. So Is the car just very sensitive to things and is that why it goes on and off? Or is something wrong? I'm a student who really wants to keep this car nice like I bought it.

- Ford vehicles commonly have this problem. Their is a sensor that determines the flow of the EGR. This sensor is called Differential Pressure Feedback Sensor or (DPFE). originally the cougar's came with a plastic DPFE they became brittle from the high engine bay temperatures. There was a newer revised part that is now metal to withstand high heat. 86k miles is roughly when you see them go bad. 9 times out of 10 on a ford the sensor is bad not the ExhaustGasRecirculation Valve. I say replace the sensor, or pay to have it diagnosed properly. And a loose gas cap will give you a gross evap leak code not a egr code.

- Q: Compare and contrast stenosis and regurgitation (insufficiency) in terms of the functional abnormality associated with the valve leaflets and their effects on hemodynamic parameters such as stroke volume.

- stenosis okorder /

- Q: We are using safety valves of gas and steam for detergent slurries. Why they do not function?

- Not sure but I would check for corrosion inside the valves. I assume the valves are positioned so that they are not exposed directly to the slurry. If possible, empty the system and test with compressed air to see if the release at the correct pressure. It is very important that this type of safety device work correctly. Also suggest contacting the mnfr. You get what you pay for so I recommend that you do NOT skimp on investment in safety equipment, consider the cost if the safety equipment fails to do what it is intended to do. Killing employees is not very popular with surviving employees and it costs a LOT of money.

- Q: I acquired an old valve guitar amp not long ago and i think it needs new valves trouble is the valves that are in it have no writing left on them and there is one valve completely missing how can i find out what type of valves to put in it. Could i use a multi meter to see what voltage etc is going into the valve socket and then find a valve with matching voltage. Thanks for your help Marc

- Go okorder and search for the schematic diagram for your amp(enter the brand and model of your amp)!

- Q: I have the correct tools and have done this before. All I want to do is change all three valves that operate the water (hot,diverter,cold). The shower is leaking. I want to change all three valves to stop the leak. I will call a plumber if I can't change the valves or stop the leak. Please tell me what tools I need and I'll begin from there. I have three handles/valves in the shower(cold,diverter,hot).The cold is here # and the diverter is in the center which is here # and the hot is here #. They all line up like this c# diverter# h#. These are how the valves are set up # # #.

- Drill out the set screw. It's most likely brass and will drill out easily. Cut an access in the wall behind your shower wall and just replace the whole thing. This will probably be the easiest fix. It may sound like a lot, but in the end you will most likely save time.

- Q: i was told my egr valve needs to be replaced, so im wondering if the system cleaner will help at all. thanx

- unlikely. A EGR pulls unburnt gases out of your exhaust and recycles them into your intake. Gumout may well be burned interior your cylinders to get rid of carbon deposits in the block and not lots if any may well be waiting to get recycled on your EGR. you may eliminate your EGR and soak it in carburetor purifier in one day to loosen the deposits and then use a mild brush to get the obdurate airborne dirt and dirt out. be careful while soaking the valve nonetheless, the (i do no longer understand the technical term) rubber areas on the interior may well be broken by ability of carb purifier so attempt to soak as lots of the metallic areas as you may in it and shop that rubber area dry. $40 5 isn't undesirable for a clean valve by ability of ways. a clean one in my truck is over $a hundred and thats seen much less costly by ability of a few.

- Q: I own a 2wheel drive 2003 Hyundai Santa Fe 4cly. The engine light was on the code P0401 came up which is the EGR valve. I had it changed out the engine light came back on after I had made it almost home. I took it to auto zone same code came up that made me take to the shop for repair in the 1st place. Ugh. Please help! What's the problem???

- I've never seen an EGR valve failure on these engines. It's almost always the vacuum solenoid for the valve that has failed. I've also seen issues with vacuum lines breaking or becoming plugged but that's pretty rare. It's just a shame that so many shops have parts throwers nowadays, get a code for the EGR valve and instead of taking 2 minutes to use a vacuum pump to test the valve, they just replace it, and then not even bother to drive the vehicle before giving it back to confirm their repair... terrible! They are giving the people who try a bad name.

- Q: My Dr placed me in the care of a cardiologist who ran some test and an echo scan reports i have a leaking valve but she failed to tell me which one and i failed to even think to ask. What are the results of leaking heart valves? I asked my mother and she says each one has a different result. What are they? Any help would be great. thanks.

- All of them equal greater stress on the heart, because if blood leaks in, then the heart fills somewhat beyond capacity and causes it to become stressed in the process of contraction.

Send your message to us

Hydraulic plate valve from okorder.com with high quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 23 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords