HRB335 Deformed Steel Bar with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

HRB335 Deformed Steel Bar with Cheap Price

Description of HRB335 Deformed Steel Bar:

1, Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40mm HRB335 Deformed Steel Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of HRB335 Deformed Steel Bar:

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

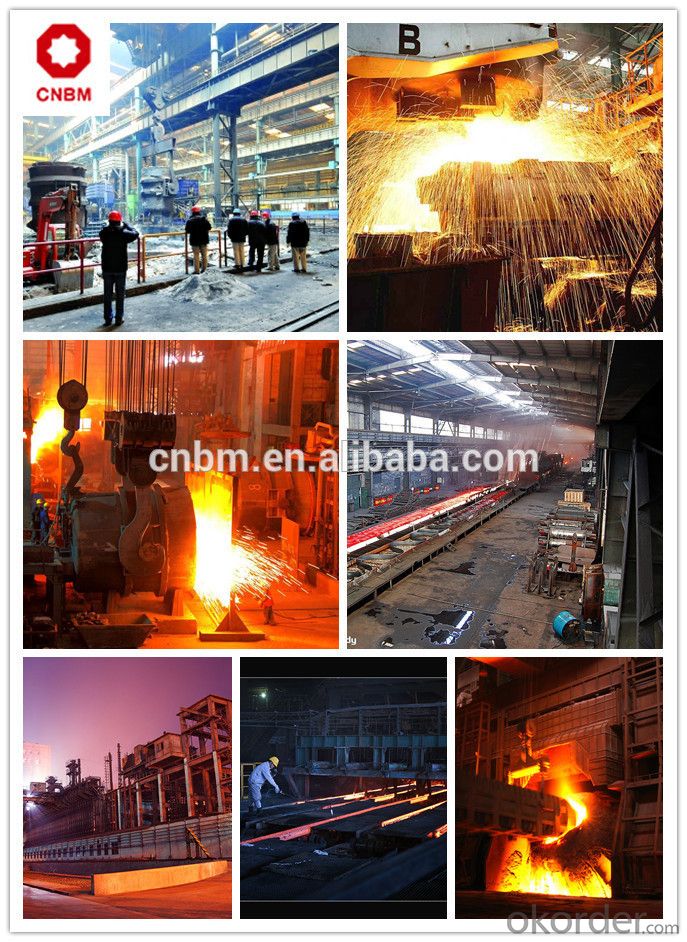

Product Show of HRB335 Deformed Steel Bar:

Workshop

Company Information:

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

FAQ:

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Contact Us:

- Q: How does special steel contribute to the aerospace aftermarket industry?

- Special steel plays a crucial role in the aerospace aftermarket industry by providing critical components that are essential for the safe and efficient operation of aircraft. The high strength, durability, and temperature resistance of special steel make it an ideal material for various aerospace applications. One of the primary ways special steel contributes to the aerospace aftermarket industry is through the production of engine components. Special steel alloys, such as nickel-based superalloys, are used to manufacture turbine blades, compressor discs, and shafts, which are vital elements of jet engines. These components must withstand extreme temperatures, pressures, and mechanical stresses, and special steel alloys offer the necessary properties to ensure reliable and long-lasting performance. Moreover, special steel is also used in the manufacturing of structural components in aircraft. Steel alloys with high strength-to-weight ratios, such as titanium alloys, are employed for the construction of critical parts like landing gear, wing spars, and fuselage frames. These components need to be both lightweight and strong to withstand the forces and stresses experienced during flight. Special steel alloys provide the required mechanical properties to ensure the structural integrity and safety of the aircraft. In addition to engine and structural components, special steel also contributes to the aerospace aftermarket industry through the production of fasteners, bearings, and other small yet vital parts. These components are responsible for holding various parts together and ensuring proper functioning of systems. Special steel alloys with excellent corrosion resistance, fatigue strength, and wear resistance are utilized to ensure the reliability and longevity of these critical components. Furthermore, special steel plays a crucial role in the maintenance, repair, and overhaul (MRO) activities of the aerospace aftermarket industry. With the rigorous demands placed on aircraft components, regular inspections, repairs, and replacements are necessary to ensure their continued airworthiness. Special steel materials are often used for MRO purposes due to their compatibility with existing aircraft systems and their ability to meet the stringent requirements of aerospace regulations. Overall, special steel is an indispensable material in the aerospace aftermarket industry. Its unique properties and characteristics enable the production of high-performance engine components, lightweight structural parts, and reliable small components. The use of special steel ensures the safety, efficiency, and longevity of aircraft, contributing to the overall success and growth of the aerospace aftermarket industry.

- Q: What are the requirements for special steel used in pharmaceutical manufacturing?

- The pharmaceutical manufacturing industry demands stringent requirements for special steel. To guarantee the safety, purity, and effectiveness of the products, the steel must adhere to specific specifications and meet various criteria. Foremost, the steel used in pharmaceutical manufacturing must be of top-notch quality and possess exceptional corrosion resistance. This is vital to prevent any contamination or reaction with the pharmaceutical compounds or chemicals involved. It is imperative that the steel does not release any impurities that could compromise the purity of the final product. Additionally, the steel must be capable of withstanding high temperatures and pressures, as pharmaceutical manufacturing processes often involve heat treatment, sterilization, and other high-temperature operations. It is crucial that the steel maintains its structural integrity and does not affect the quality of the pharmaceutical products under these conditions. Another significant requirement for the steel used in pharmaceutical manufacturing is easy cleanability. The steel should have a smooth surface without any cracks, crevices, or rough areas that could trap bacteria, contaminants, or residues. This is essential to maintain the hygiene and sterility of the manufacturing environment and ensure that the pharmaceutical products meet the highest quality standards. Furthermore, the steel must comply with regulatory standards and industry guidelines. It should meet the specific requirements set by regulatory bodies such as the Food and Drug Administration (FDA) or the European Medicines Agency (EMA). These standards often include specifications regarding the composition, mechanical properties, and traceability of the steel. In conclusion, the requirements for special steel used in pharmaceutical manufacturing are strict and encompass factors such as top-notch quality, corrosion resistance, heat resistance, cleanability, and compliance with regulatory standards. Meeting these requirements is vital to guarantee the safety, purity, and effectiveness of the pharmaceutical products manufactured using this steel.

- Q: Can special steel be used in the appliance manufacturing industry?

- Yes, special steel can be used in the appliance manufacturing industry. Special steel, also known as alloy steel, offers enhanced properties such as durability, corrosion resistance, and high temperature resistance. These qualities make it suitable for various appliance components, including heating elements, motor shafts, and structural parts.

- Q: What are the main advantages of using special steel in the construction industry?

- The main advantages of using special steel in the construction industry are its high strength and durability, which allows for the construction of structures that can withstand heavy loads and harsh environmental conditions. Special steel also offers excellent resistance to corrosion, making it suitable for use in coastal or industrial areas. Additionally, special steel is highly versatile and can be easily fabricated and shaped, providing flexibility in design and construction.

- Q: How does special steel contribute to the aerospace fuel efficiency?

- Special steel contributes to aerospace fuel efficiency in several ways. Firstly, special steel alloys are used in the construction of aircraft engines, which helps reduce their weight while maintaining strength and durability. This reduction in weight results in lower fuel consumption as the engines require less energy to propel the aircraft. Additionally, special steel is also utilized in the manufacturing of lightweight airframe components, such as wings and landing gear, which further contributes to fuel efficiency by reducing the overall weight of the aircraft. Furthermore, special steel's corrosion resistance properties ensure the longevity of aerospace components, reducing the need for frequent replacements and maintenance, which in turn helps optimize fuel efficiency.

- Q: Can special steel be used in the automotive industry?

- Yes, special steel can be used in the automotive industry. Special steel alloys such as high-strength steel, stainless steel, and tool steel are utilized in various automotive components and structures to enhance durability, strength, and corrosion resistance. These steels are commonly used in areas such as chassis, body panels, engine components, and suspension systems, contributing to improved performance, safety, and fuel efficiency in vehicles.

- Q: How does special steel contribute to the automotive engine industry?

- Special steel plays a crucial role in the automotive engine industry by providing superior strength, durability, and performance to various engine components. The unique properties of special steel make it an ideal choice for manufacturing critical parts, such as crankshafts, connecting rods, camshafts, valves, and cylinder liners. One of the key contributions of special steel to the automotive engine industry is its exceptional strength and resistance to high temperatures. Special steel alloys are designed to withstand the intense heat and pressure generated within an engine, ensuring that these components maintain their structural integrity and functionality under extreme conditions. This durability translates into increased engine efficiency, reliability, and longevity. Moreover, special steel's superior mechanical properties, including high tensile and impact strength, allow for the production of lighter yet stronger engine components. By reducing the weight of these parts, special steel helps to enhance fuel efficiency and reduce emissions, making it an environmentally friendly choice for automotive manufacturers. Special steel also contributes to the automotive engine industry by enabling the production of more complex and precise engine components. The excellent machinability and formability of special steel alloys allow for intricate designs, tighter tolerances, and improved performance. This, in turn, contributes to the overall efficiency and power output of the engine. Furthermore, special steel's corrosion resistance properties are crucial in preventing engine components from deteriorating over time. The ability to resist rust and other forms of corrosion ensures that the engine operates at optimal levels for an extended period, reducing maintenance costs and improving overall performance. In summary, special steel's unique properties, including strength, durability, heat resistance, and corrosion resistance, make it an essential material in the automotive engine industry. Its contribution lies in providing superior performance, efficiency, and longevity to critical engine components, ultimately enhancing the overall driving experience for consumers.

- Q: What are the different casting grades of special steel?

- The different casting grades of special steel include low alloy steel, high alloy steel, stainless steel, tool steel, and heat-resistant steel.

- Q: What are the different surface finishing techniques for special steel?

- Some of the different surface finishing techniques for special steel include electroplating, powder coating, passivation, etching, and polishing.

- Q: Can special steel be used in the computer manufacturing industry?

- Yes, special steel can be used in the computer manufacturing industry. Special steel, known for its enhanced strength, durability, and resistance to corrosion, can be utilized in various components of computer manufacturing. This includes using special steel alloys for computer casings, structural frames, heat sinks, and other critical components that require high strength and reliability. The use of special steel in the computer manufacturing industry ensures the longevity and performance of computer systems.

Send your message to us

HRB335 Deformed Steel Bar with Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords