Hps 5 Geotextile High Flexibility Fiberglass Polypropylene Geogrid Roadbed Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

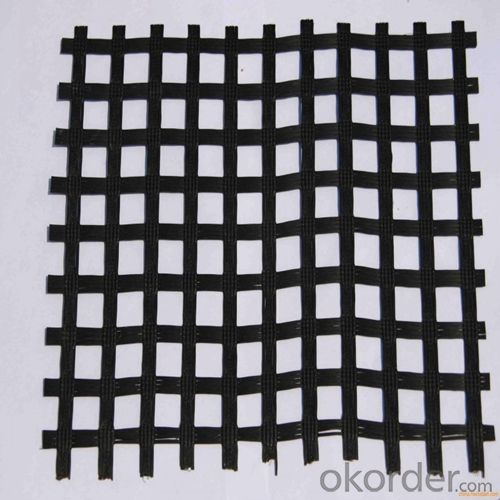

Geogrids form a distinct category of geosynthetics designed for reinforcement. These products are characterized by a relatively high tensile strength and a uniformly distributed array of large apertures (openings between the longitudinal and transverse elements). The apertures allow soil particles on either side of the installed sheet to come into direct contact, thereby increasing the interaction between the geogrid, aggregate and some soils. Also, the apertures ensure vertical drainage of a reinforced free-draining aggregate/soil.

Type:

Geogrids

Place of Origin:

Shandong, China (Mainland)

Brand Name:

Model Number:

20KN/M--50KN/M

Material:

Plastic

width:

1-6m

Certificate:

CE,ISO

Application

1. Roadbed reinforcement in highway, railway and municipal road, prevent road surface crack

2. Reinforcement and separation in dam and river, improve soft soil bearing capacity and stability.

fiberglass geogrid/glass fiber geogrid with CE certificate Introduction: Fiberglass geogrid is a kind of new favorable earthwork base material to strengthen the road surface and roadbed. This product is composed of fiberglass filaments that are coated with an inorganic sizing agent

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

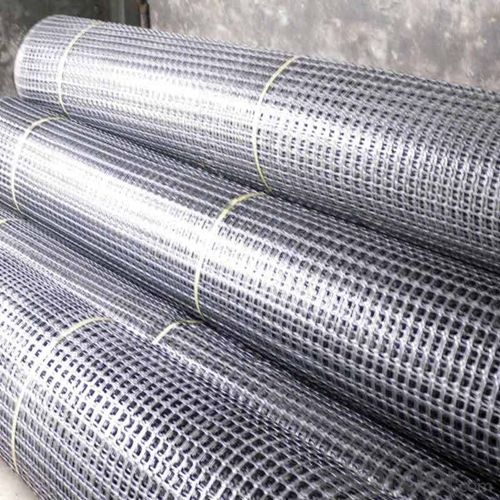

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Are geotextiles resistant to acid degradation?

- Yes, geotextiles are generally resistant to acid degradation. They are designed to withstand various environmental conditions, including exposure to acid or acidic substances, without significant degradation or damage.

- Q: Acupuncture geotextile is divided into several kinds of how is it used?

- Acupuncture geotextile is now divided into two types, according to the fiber form to points. Continuous fiber called filament acupuncture non-woven geotextile. A few centimeters of length fibers made of staple fibers for nonwoven geotextiles. Use is not used, mainly used in geotechnical engineering in the filter, isolation, drainage and so on.

- Q: What are the environmental impacts of geotextile production?

- The environmental impacts of geotextile production include energy consumption during manufacturing, emissions of greenhouse gases, water and air pollution from chemical processes, and the generation of solid waste. However, compared to traditional construction materials, geotextiles have lower environmental impacts in terms of resource consumption, carbon emissions, and waste generation.

- Q: Where can the general use of geotextile water can be bought

- Lingxian geotextile manufacturers, welcome to visit

- Q: What is a polyester filament geotextile? Polyester filament geotextile

- In addition to a good mechanical energy, but also has a good vertical and horizontal drainage and good extension of energy and high resistance to biological, acid and alkali, anti-aging and other chemical stability. At the same time, also has a wide range of pore size, tortuous pore distribution, excellent permeability and filtration can be polyester filament geotextile purposes: water conservancy project dam and slope protection filter, channel isolation, seepage; Airport runway foundation isolation, filter, drainage, soil slope, retaining wall and road reinforcement, drainage; port engineering soft foundation treatment, beach embankment, harbor wharf and breakwater reinforcement, drainage; polyester filament geotextile Has been widely used in the field of infrastructure construction, and gradually applied to a wider range of areas. Polyester filament geotextile technical parameter table (GBT-1998): No. Remarks 1 unit area mass deviation% -6-6-6-5-5-5-5-5-4-4-42 thickness, mm ≥ 553 Width deviation% -054 breaking strength KNM ≥ vertical and horizontal 5 elongation at break% 40-806CBR breaking strength KN ≥ 707 equivalent aperture 090, mm007-02

- Q: How do geotextiles help in preventing piping in dams?

- Geotextiles help in preventing piping in dams by acting as a filter and drainage layer. They allow water to pass through while retaining the soil particles, preventing their erosion and subsequent formation of preferential flow paths. This helps maintain the stability and integrity of the dam, reducing the risk of piping and potential failure.

- Q: What is the length of the lap in the geotextile in the tunnel?

- Lap 20 cm Huazhi geotextile material answer

- Q: Filtering geotextile calculation

- Professional advice manufacturers, music built

- Q: Can geotextiles be used in underground storage tank applications?

- Yes, geotextiles can be used in underground storage tank applications. Geotextiles are often employed as a protective barrier or liner to prevent soil erosion, provide filtration, and enhance drainage in various construction projects, including underground storage tanks. They can help in maintaining the structural integrity of the tank by preventing soil migration and reducing the risk of contamination.

- Q: How are geotextiles tested for strength and durability?

- Geotextiles are tested for strength and durability through various methods such as tensile strength tests, puncture resistance tests, tear strength tests, and abrasion resistance tests. These tests involve subjecting the geotextile to controlled forces and conditions to determine its ability to withstand different types of stresses and strains. Additionally, long-term exposure tests are conducted to assess the geotextile's durability under simulated environmental conditions, ensuring its performance over time.

Send your message to us

Hps 5 Geotextile High Flexibility Fiberglass Polypropylene Geogrid Roadbed Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords