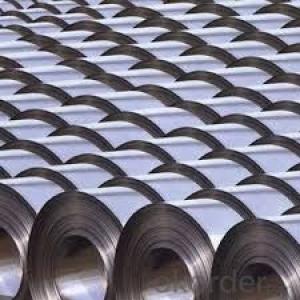

Hot Steel Rolled/jis g3141 spcc steel coil SPCC SPCD SPCE

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

JIS g3141 spcc cold rolled steel coil

Grade :SPCC,SPCD,SPCE

Width:600-1500mm

WT:0.15-3mm

Product Feature

Packaging Details: Wrapped by water prove paper and plastic film, covered by steel sheet, strapped with steel strips to prevent damage from transportation

Product Specification / Models

Standard: AISI, ASTM, DIN, GB, JIS

Grade: Q195, SPCC, SPCD, SPCE, DC01-0S, St12, ST14, ST15, ST16

Thickness: 0.2mm-2.0mm

Place of Origin: Tianjin, China (Mainland)

rand Name: TianJin MuChang

Model Number: 0.2-2.0mm*600-1500mm

Type: Steel Coil

Technique: Cold Rolled

Surface Treatment: oiled

Application: Construction,mechine,building,container manufacture,shipping building,

Special Use: High-strength Steel Plate

Width: 1000mm,1200mm,1219mm,1250mm,1500mm or as per customer's request

Length: Coil or as customs' request

Carbon constructional steel: SPCC,St12,DC01,Q235A/B/C/D Constructional quality steel: 20-45#,08-15#

Carbon quality steel coil: 08AL,Z,S,P SPCD,ST14

Low carbon deep-drawing coil: SC1,SPCE,SPCEN,ST14,DCO4 Extra-deep drawing coil: SC2,ST15,DCO5,SC3,ST16,DCO6,ST17 Corrosion-resistant steel: 05CuPCrNi,09CuPCrNi,Q345GNHL

Low carbon drawing steel: SPCD,ST13,DC03

Steel Coil: COLD ROLLED

Certificate: ISO, SGS, BV

Application

1.common structural parts and parts for drawing in engineering machines

2. transportation machine construction machines, lifting machine,

3. agricultural machines, light and civil industrial, household appliance industries.

4. chemical equipments, drive casing pipe and light industrial civil industries.

Other Information

Name Cold Rolled Steel Sheet Coil

GB11253-89,Q195 Q235,IS G3141,SPCC SGCC SPCD SPCE,DIN1623,ST12 ST13 SPCD ST14, EN10130,DC01 DC02,DC03

Thickness 0.18-3.0mm

Width 680mm-2000mm or 1000/1200/1219mm/1250mm

Finish General, bright, dull and mirror finish, oiled or non-oiled

Coil ID 508mm

Coil weight 5-12 tons.

Packing as client's requirement

Certificate ISO9001:2008

Standard GB11253-89, JIS G3141,DIN1623,EN10130

- Q: Why does steel with several composites have a greater hardenability from quenching than low carbon steel alloys?Any help would be great

- Bit tricky to explain and I don't know muh about it but steel on its own has lost of gaps in it ( the molecular structure) and when carbon is added thos gaps are filled, I think of it like this: it is easier to punch through expanded polystyrene( with all the little balls) than unexpanded(just a lump of plastic) as the balls are not properly joined and have air pockets between them.

- Q: How are steel coils used in the production of agricultural structures?

- Due to their exceptional strength and durability, steel coils find extensive use in the production of agricultural structures. These coils, typically composed of high-quality steel, have various applications within the agricultural industry. One major application of steel coils in agricultural structures involves the construction of buildings and storage facilities. By using steel coils, farmers can create robust frameworks that support the walls and roofs of these structures. The inherent strength of steel allows for the construction of spacious areas without the need for excessive support columns, providing farmers with ample storage space for their crops, machinery, and livestock. Furthermore, steel coils play a crucial role in the manufacturing of agricultural equipment and machinery. Whether it be tractors, plows, harvesters, or irrigation systems, steel coils are essential in the fabrication of these tools. The high tensile strength of steel ensures that these agricultural machines can endure the rigorous conditions of farming, including heavy loads, rough terrains, and exposure to harsh weather elements. Moreover, steel coils are also indispensable in the production of fencing and enclosures for agricultural purposes. Whether it's safeguarding crops from animals or establishing boundaries for livestock, steel coils are a vital component in constructing robust and reliable fences. The strength of steel guarantees that these fences can withstand the pressure from animals, preventing them from breaking through and causing harm to the crops or escaping. In conclusion, steel coils are a vital component in the production of agricultural structures and equipment. Their strength, durability, and versatility make them an ideal material for constructing buildings, manufacturing machinery, and creating fences in the agricultural industry.

- Q: i have a guitar with three nylon three steel strings. Am i able to replace the nylons with steel strings?

- earlier you circulate approximately any extensive alterations, take the guitar to a qualified technician and notice approximately having the strings, or action diminished nearer to the fretboard. this could take very numerous soreness off of his palms, because it feels like the guitar hasn't been set-up in any respect, or a minimum of superb. A neck adjustment, if mandatory, might additionally help this issue. If he continues to be experiencing finger soreness (he might might desire to undergo some), attempt a lighter gauge set of strings (steel). a good tech can help you there, too. Nylon strings are not going to paintings properly in any respect on a non-classical guitar; the parameters are in basic terms different adequate between the two certainly one of them to end not something greater suitable than to waste your money. the main uncomplicated issue I see on a conventional foundation is that guitars are offered and offered without suitable set-up. An experienced tech will examine the neck configuration; the bridge alignment; saddle top; venture end; nut clearance; and action on an acoustic guitar. There are much greater info on an electric powered. Please detect a music/guitar save that does this form of paintings on the premises. My concept is that the finished relatives will income. Cheers decrease back atcha!

- Q: .Yea, so I just saw the old Conan movie with Arnold. Good movie, but I still don't get it. What IS the riddle of steel???I get that like from the begining Conan's dad is like telling him a story about Crom and giants, and people got steel once Crom killef the giants. Then, later on in the movie Conan's talking to his lil' asian homie, and Conan tells him that when he dies... he'll go before Crom, and Crom will ask him what the riddle of steel is, and if he doesn't know it he'll get kicked out of barbarian heaven!But, what is the riddle of steel???C'mon guys... I want to in to barbarian heaven! LolBut, seriously though... what us it???.

- Riddle Of Steel

- Q: Can steel coils be coated with phosphorescent materials?

- Yes, steel coils can be coated with phosphorescent materials. The phosphorescent coating can be applied to the surface of the steel coils, allowing them to emit a glow in the dark or low-light conditions.

- Q: What are the different coil packaging options available for steel coils?

- Customers have a range of coil packaging options to choose from for steel coils, depending on their specific requirements and preferences. Some commonly used packaging options include the following: 1. Traditional steel strapping is used to secure the coil, ensuring excellent stability and protection during transportation and storage. 2. Plastic strapping is a lighter and more cost-effective alternative to steel strapping, suitable for smaller and lighter steel coils while still providing sufficient strength and protection. 3. Shrink wrapping involves using heat to tightly seal a plastic film around the steel coil, offering protection against moisture, dust, and other contaminants. 4. Wooden crates provide additional protection against physical damage during handling and transportation. They can be customized to fit the coil's dimensions and secured with straps or nails. 5. Coil covers are heavy-duty plastic or fabric covers that shield the steel coil from environmental factors like UV exposure, moisture, and dust. They are often used in combination with other packaging methods. 6. Paper or fiberboard wrapping offers a lightweight and cost-effective solution for protecting the coil against minor scratches and abrasions. 7. Customized packaging allows for a combination of the above options or tailor-made solutions based on specific requirements. This may involve additional padding, corner protectors, or special handling instructions to ensure safe transportation and storage. Customers should consider factors such as coil size, weight, transportation mode, storage conditions, and budget to choose the most suitable coil packaging option for their needs.

- Q: I have a bottle like this* Can u make hot chocolate in it. Can i heat it.I wanna take hot Chocolate to school

- Stainless okorder /... on Hot Drink in Stainless Steel Water Bottle.

- Q: What are the dimensions of steel coils used in the mining equipment industry?

- The dimensions of steel coils utilized in the mining equipment sector may differ depending on the particular application and demands. Nevertheless, there are frequently employed standard dimensions. Typically, the width of steel coils used in the mining equipment industry can range from 600mm to over 2000mm. This allows for adaptability in the manufacturing process and guarantees that the coils can be customized to fit different equipment sizes and specifications. Regarding thickness, steel coils employed in mining equipment can range from 1.5mm to 20mm or more. The specific thickness is determined by factors such as equipment type, intended usage, and required durability level. The length of steel coils used in the mining equipment industry can also vary, but usually falls within the range of 1000mm to 6000mm. Once again, this offers flexibility in the manufacturing process and ensures that the coils can be cut to suit the exact requirements of the equipment being produced. It is essential to acknowledge that these dimensions are not fixed and can be tailored to meet the specific needs of the mining equipment sector. Manufacturers and suppliers in the industry can often provide coils in different sizes and dimensions to accommodate the wide array of equipment used in mining operations.

- Q: Hi, does anyone know where i can find more about this topic ? fire resistant steels for structural applications. thanks

- There is a chemical that is used presently that is sprayed onto steel beams called Monocoat. Its a form of insulation that gives steel protection for up to 2 hours I think. Hope that helps!

- Q: Personally, I like Steel Cage matches to end in pinfalls. One of the biggest selling points of a Cage match is that it is to keep the competitors in and keep others out; essentially ensuring that it's a 1 on 1 match. As a result, I believe that pinfalls or submissions are important - but I know there's a lot of people that believe cage matches should only end in escape. What do you think??

- I don't really care either way. The only way I don't like it to end is when the door is opened and the person just walks out. That really isn't hard to win it like that. For last night I was hoping before the match that Bryan would win by escaping the cage. It fit his character, being a coward champ.

Send your message to us

Hot Steel Rolled/jis g3141 spcc steel coil SPCC SPCD SPCE

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords