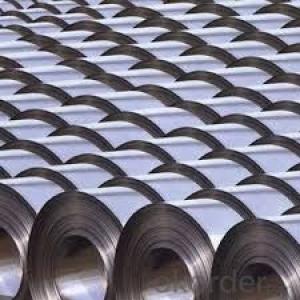

Matt Finish Cold Rolled Steel-JIS G3141 SPCC-3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATION

1) Capacity: about10,000 ton per month for steel strip/tape product

2) Thickness: from 0.20mm to 3.5mm, all available.

3) Width: from 15mm to 600mm, all available.

4) Grade: Q195, SGCC, DX51D

5) Coil weight: from 50kg to 7000kg, all available.

6) Coil ID: 100mm - 508mm

7) Coil OD:500mm-1300mm

9) Tensile strength: 28.1-49.2kgf/mm2

10) Zinc coating weight: Min. 60g/m2, double side

11) Spangle: regular spangle, minimized spangle, zero spangle

12) Surface treatment: chemical passivating treatment, oils,passivating oils

13) Min trial order 5ton each thickness, 1 x 20' per delivery

14) Components: C%≤ 0.07, Si%≤0.03, Mn% ≤ 0.50, P% ≤ 0.025,S% ≤ 0.025, Alt% ≥ 0.02

It is the basedmaterial for galvanized steel coil and pre-painted galvanized steel coil. It iswidely used in light industry for making tank, furniture, pipe, refrigerators,washers, freezer plate, air conditioner, micro-wave oven, water heater,soot-such machine, electric rice cooker, electric roaster oven, dryers andautomobile etc. In the other application industries, it’s mainly used forenameling, office furniture, burglarproof door, electronic element, fastenerbattery, hardware, automotive fitting etc.

Eye to sky package: Anti-damp paper inside fullwrapped with plastic film, iron sheet outside on wooden pallet in 20 feetcontainer with 25mt.

- Q: Can you recycle steel? And if you wanted to buy some recycled steel, where would you get it?

- Yes; steel can be recycled. Look on the Internet for dealers who sale recycled steel. Good luck! Smile!

- Q: What are the challenges in coil blanking?

- Coil blanking, a process used to cut flat metal sheets from coiled stock, presents several challenges that need to be addressed for efficient and accurate production. Some of the key challenges in coil blanking include: 1. Material variations: Coiled stock can have variations in thickness, width, and surface quality. These variations can affect the cutting process and result in inconsistent blanks. Proper material selection and control are crucial to ensure consistent quality and dimensional accuracy. 2. Coil set and crossbow: Coiled stock often has inherent shape imperfections like coil set (longitudinal curvature) and crossbow (transverse curvature). These imperfections can cause alignment issues during the cutting process, leading to misalignment and inaccurate blanks. Specialized equipment and techniques, such as straighteners and leveling systems, are required to minimize these shape imperfections. 3. Coil edge condition: The edges of coiled stock can have burrs, waves, or irregularities, which can affect the quality and precision of the cut blanks. Adequate edge conditioning techniques, such as deburring or edge trimming, need to be employed to ensure clean and straight edges for the final blanks. 4. Slitting and shearing forces: The forces exerted during the coil blanking process can induce stresses and strains in the material, potentially leading to deformation or springback. These factors can result in dimensional variations and affect the overall quality of the finished blanks. Careful consideration of the slitting and shearing forces, along with proper tooling design and machine settings, is necessary to minimize these effects. 5. Scrap and material waste: Coil blanking can generate significant amounts of scrap material, especially during setup and adjustment phases. Managing scrap and minimizing material waste are critical challenges in coil blanking to optimize production efficiency and reduce costs. Efficient nesting algorithms and real-time monitoring systems can help optimize material utilization and minimize waste. 6. Automation and productivity: Coil blanking processes often require high-speed and high-volume production to meet market demands. Implementing automation systems, such as robotic material handling and advanced control systems, can enhance productivity. However, integrating and synchronizing these automation components with the cutting process can be challenging and requires careful planning and system integration expertise. Overall, addressing these challenges in coil blanking requires a combination of proper material selection, advanced equipment, specialized techniques, and efficient process control. By overcoming these challenges, manufacturers can achieve consistent quality, dimensional accuracy, and productivity in coil blanking operations.

- Q: How are galvanized steel coils different from regular steel coils?

- In terms of their protective coating, there is a difference between galvanized steel coils and regular steel coils. Galvanized steel coils have a layer of zinc coating, which serves as a barrier against corrosion and rust. This process, called galvanization, involves immersing the steel coils in a bath of molten zinc or applying zinc to the surface using different methods. On the other hand, regular steel coils lack this protective coating, making them more prone to corrosion and rust. The zinc layer on galvanized steel coils not only functions as a physical barrier but also provides sacrificial protection. This means that if the coating is scratched or damaged, the zinc sacrifices itself to shield the underlying steel from corrosion. Consequently, galvanized steel coils are highly durable and suitable for applications that require resistance to harsh environmental conditions. These applications include outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: what is the chemical process that makes steel harder when it is heated and cooled rapidly?what does the heating of it do to the atoms?what does the cooling of it do to the atoms?what makes tempered steel so strong compared to untempered steel?

- You can't temper all steels. Generally the material must be a high-carbon or tool steel. Different alloys temper differently, and tempering is usually done to get a specific set of characteristics, so you must know what you are working with and use the right methods and temperature. If you do it wrong, the material may be hard but too brittle for the purpose or have other issues. It can be simple, such as heating to a dull red, carbonizing the surface (use an acetylene rich flame until it blackens the surface) and oil quenching. Do that to a piece of tool steel (like a screwdriver) and it will case (surface) harden it to the point you can't scratch it with a file. Tempering changes the way the molecular structure in the metal is linked and oriented.

- Q: What are the different types of surface finishes for steel coils?

- Steel coils can be finished in various ways, each with its own unique properties and advantages. Here are some of the most common surface finishes for steel coils: 1. Hot Rolled: Achieved by heating the steel and rolling it, this basic finish results in a rough and scale-like appearance with varying levels of imperfections. 2. Cold Rolled: This finish is obtained by subjecting hot rolled steel coils to a series of cold rolling operations. It yields a smoother and more uniform surface with improved dimensional accuracy and surface quality. 3. Galvanized: In this process, a protective layer of zinc is applied to the steel coil's surface, offering excellent corrosion resistance. It is ideal for outdoor applications and environments exposed to moisture and corrosive elements. 4. Stainless Steel: Stainless steel coils have a distinctive finish due to the presence of chromium, which forms a thin, invisible oxide layer. This finish provides exceptional corrosion resistance and an appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this finish involves applying a thin layer of zinc to the steel coil through electroplating. It offers good corrosion resistance and is commonly used in applications that prioritize aesthetics. 6. Pre-painted: Pre-painted steel coils have a surface finish coated with paint or other protective coatings. This finish provides corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes. 7. Aluminized: Aluminized steel coils are coated with an aluminum-silicon alloy, providing excellent heat resistance. They are commonly used in high-temperature applications like exhaust systems or ovens. Ultimately, the choice of surface finish for steel coils depends on specific requirements such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: What is the market demand for steel coils?

- The market demand for steel coils is influenced by various factors such as economic growth, construction and infrastructure projects, automotive manufacturing, and consumer goods production. It fluctuates based on these industry trends and overall market conditions. Currently, the market demand for steel coils is significant due to increased construction activities, infrastructure development, and manufacturing needs globally. However, it is important to note that market demand can vary regionally and may be subject to short-term fluctuations based on specific economic and industrial factors.

- Q: case hardening steel is adviced or thru hardening steel is most suitable?

- I don't know your application, but here is some advice. Case hard provides a hard shell around soft steel, depending on the bake, the case is usually .002-.008 thick. (thousands of an inch) Heat treated steel or tool steel is hard all the way thru. Case hardening, provides toughness with flexibility, however, once it's compromised, the part is scrap. Hardend tool steel is extreemly hard throughout and the harder it is, the more brittle it becomes. The application of the part will help you to determine the material needed. For instance; Plastic injection molds are very hard so the hot plastic wont erode them over years of use. Punch Press dies aren't as hard but are tougher to withstand the shock. Machine bolts are case hardened so they can last, but soft enough to allow some stretching during tightening. Either way, the time in mfg will be about the same. Most tool steels today cut like cheese, but take time to be heat treated. Tool steel will cost a bit more than low carbon steel. Low carbon steel is as machinable, and cheaper, but, again, the baking period is as long or longer than tool steel. There are a lot of materials on the market today that maintain the durability of heatreated steel without having to go thru that process. 4140, ( or chrome/moly) comes to mind. There are also some 400 series stainless that work as well, and others. You need to determine strength, flexibility, ease of mfg, cost and repairability when considering which steel to use.

- Q: can u use stainless steel to make a coin? why or why not? answers based on facts plz.

- Stainless steel has been used by some countries to make coins, but it's not an ideal metal. When a coin is struck, a die comes down and strikes the blank with many tons of force (the blank is also sitting on top of another die--one has the image on the obverse (front) of the coin, while the other die has the image of the reverse of the coin). When the die strikes the blank, the force causes the metal in the blank to flow into the recesses of the die. The problem with stainless steel is that it doesn't want to flow into the die. To get an image, either the relief (how high the raised portion of the design will be) has to be very low, and the coin has to have a simple design, or they have to greatly increase the pressure of the strike. This slows the coining press down, and greatly shortens the life of the dies.

- Q: Can steel coils be used in outdoor applications?

- Indeed, outdoor applications can make use of steel coils. Steel, recognized for its resilience and robustness, proves to be ideal for various outdoor purposes. Commonly utilized in construction, automotive manufacturing, and transportation industries, steel coils exhibit resistance against adverse weather conditions like rain, snow, and UV exposure. Furthermore, to enhance their durability and prolong their lifespan, steel coils frequently undergo protective finishes such as galvanized or painted coatings. Ultimately, owing to their strength, durability, and ability to withstand environmental factors, steel coils emerge as a dependable and versatile choice for outdoor applications.

- Q: i heard steel type is good and i don't have any i have defeated all the trainers up to the icicle badge (i have got the icicle badge but not the one after) where can i get one?

- you can get a steelix at the cave just before the elite four. but if you have wifi, you can trade for one.

Send your message to us

Matt Finish Cold Rolled Steel-JIS G3141 SPCC-3

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords