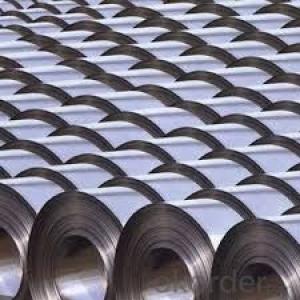

Matt Finish Cold Rolled Steel-JIS G3141 SPCC-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

SPECIFICATION

1) Capacity: about10,000 ton per month for steel strip/tape product

2) Thickness: from 0.20mm to 3.5mm, all available.

3) Width: from 15mm to 600mm, all available.

4) Grade: Q195, SGCC, DX51D

5) Coil weight: from 50kg to 7000kg, all available.

6) Coil ID: 100mm - 508mm

7) Coil OD:500mm-1300mm

9) Tensile strength: 28.1-49.2kgf/mm2

10) Zinc coating weight: Min. 60g/m2, double side

11) Spangle: regular spangle, minimized spangle, zero spangle

12) Surface treatment: chemical passivating treatment, oils,passivating oils

13) Min trial order 5ton each thickness, 1 x 20' per delivery

14) Components: C%≤ 0.07, Si%≤0.03, Mn% ≤ 0.50, P% ≤ 0.025,S% ≤ 0.025, Alt% ≥ 0.02

It is the basedmaterial for galvanized steel coil and pre-painted galvanized steel coil. It iswidely used in light industry for making tank, furniture, pipe, refrigerators,washers, freezer plate, air conditioner, micro-wave oven, water heater,soot-such machine, electric rice cooker, electric roaster oven, dryers andautomobile etc. In the other application industries, it’s mainly used forenameling, office furniture, burglarproof door, electronic element, fastenerbattery, hardware, automotive fitting etc.

Eye to sky package: Anti-damp paper inside fullwrapped with plastic film, iron sheet outside on wooden pallet in 20 feetcontainer with 25mt.

- Q: What are the safety precautions when working with steel coils?

- When working with steel coils, it is important to follow several safety precautions. Firstly, workers should always wear the appropriate personal protective equipment (PPE) such as safety glasses, gloves, and steel-toed boots to protect themselves from potential hazards. Additionally, it is crucial to ensure that the work area is clean and free from any debris or obstacles that may cause accidents or tripping. Proper manual lifting techniques should be employed to avoid strain or injury when handling heavy steel coils. Workers should also be trained in the proper use of equipment such as cranes or forklifts to safely transport and store the coils. Regular inspections of equipment and proper maintenance should be conducted to prevent any malfunctions or accidents. Lastly, employees should be aware of emergency procedures and have access to fire extinguishers and first aid kits in case of any unexpected incidents. Overall, prioritizing safety measures and being vigilant can greatly minimize the risks associated with working with steel coils.

- Q: Hi, I live in the Boston area and I'm trying to find a steel suppler that can provide mild steel for hobby welding. I can go through my job, but we only put in orders every couple of months so it's not very convenient. Also, the few suppliers I've found only sell in bulk. So if anyone knows where I can angle irons, flat bars, sheets, etc... by the piece it would greatly appreciated. Thanks

- They will sell any quantity of metal and even cut it to size - my experience has been that their prices are not wildly out of line for single pieces of full length stock compared to buying singles where you have to buy a minimum. They also may have sizes that ordinary places consider odd. I was looking for 5/8 square 16 gauge and was told it would have to be shipped in from Houston (to Dallas) by my nearest supplier and found it in stock at MetalSM. But check if you get something odd - the 5/8 cost more than 3/4 at both places and MetalSM actually gave me 3/4 but took it back even though I had cut it. Also check the regular steel suppliers in your area as well as retail welders metal supply places.

- Q: What are the different types of steel coil surface defects?

- During the manufacturing or handling process, various steel coil surface defects may arise. Some commonly encountered types are as follows: 1. Rust: When moisture or oxygen comes in contact with the steel coil, rust, a reddish-brown discoloration, may develop on its surface. 2. Scratches: While the steel coil is being handled or transported, superficial marks known as scratches can be incurred. These marks can vary in depth and severity, ranging from light surface scratches to deep gouges. 3. Stains: Exposure to chemicals or other substances can lead to stains, discolored patches that appear on the coil's surface. Removing them may prove to be challenging. 4. Roll marks: During the rolling process, impressions or indentations called roll marks may form. Uneven pressure or misalignment of the rolls causes them, resulting in lines or patterns on the coil's surface. 5. Edge wave: Imperfectly flat edges of the coil can result in a defect known as edge wave. This defect causes the edges to appear wavy or uneven and can impact the coil's overall appearance and performance. 6. Oil spots: If the oil or lubricants utilized in the manufacturing process are not adequately removed, surface defects called oil spots can manifest. These spots appear as dark patches or spots on the coil's surface and may hinder the adhesion of coatings or paints. 7. Pitting: Small, shallow depressions or pits on the coil's surface are indicative of a defect called pitting. Factors like corrosion, uneven cooling, or impurities in the steel can cause this defect. 8. Holes: Holes are severe surface defects that can arise due to various factors, including corrosion, mechanical damage, or manufacturing errors. These defects come in different sizes and can significantly compromise the coil's structural integrity. Promptly addressing these surface defects is crucial for maintaining the quality and performance of the steel coil. Regular inspections, proper handling, and appropriate surface treatments can help minimize the occurrence of these defects.

- Q: What's the best material for color coated steel coil?

- Galvanized steel sheet with hot-dip galvanized or zinc plated surface.

- Q: what does steel have inside of it that makes it rust.I need the answer fast!!!!!!!!!

- Steel is made by refining iron. Iron is mined as a red powdery ore. Unfortunately, when moisture and oxygen are present, the steel attempts to revert to its original state.

- Q: What are the applications of steel coils in the aerospace industry?

- Steel coils have various applications in the aerospace industry, primarily in the manufacturing of aircraft components. These coils are used to produce structural parts, such as frames, wings, and landing gear, due to their high strength and durability. Additionally, steel coils are utilized in the fabrication of engine components, including turbine blades and exhaust systems, as they can withstand extreme temperatures and pressures. Overall, steel coils play a crucial role in ensuring the safety and performance of aircraft in the aerospace industry.

- Q: my homework is a breif description on steel pipe. for plumbing/gas.please help me i dont have a clue where to start, something about the thread and where its used.Thanks,

- Here are a few quick things for you to check into on your own. First, there are a wide variety of materials that pipes can be made from such as carbon steel, stainless steel, aluminum, etc. Second, pipes can be of welded construction or seamless. Sometimes seamless pipes are called DOM (drawn over mandrel). Third, with the types of each pipe are a variety of grades. For example, steel pipe can be listed as A53, A106, A500, A513, etc. Each one of these grades has a different application because of their chemical composition and method of manufacture which effects its strength. Fourth, there is a difference between a 4 pipe and a 4 tube. Last, pipes for fluids are typically threaded with NPT threads. These threads are tapered so that as the pipes are screwed together they become tighter and therefore leak proof. I probably over complicated things but I hope this helped you. Good luck.

- Q: does he use a nylon guitar or steel?

- He's using a nylon guitar. The trick to know whether it is nylon or steel is by looking at the headstock. steel ones use the ones you see from a regular electric guitar. the nylon ones has two major holes on them I don't know why but that's based on what i have seen. One more thing is its bridge. the nylon ones do not use pin-like stoppers to prevent the strings from falling off unlike the steel-stringed guitars that use them.

- Q: y does 1095 steel on a katana weight about a pound less for the same amount than 1045? the 1095 is better right? but then why is 1045 steel more comenly used for practical use than 1095, even though i no its cheaper to use 1045 for tami mats. so is 1095 steel the better investment for buying and minor tami mat use?

- Steel grades generally tell you how much carbon is in the steel. The higher the number the more carbon. Aside from quality of manufacture, the better swords tend to be 1060 or more. Few quality swords are made from 1045. Which DOES NOtT hold an edge better (quite the reverse). Swords made of these different steels weigh about the same. That is, if you made two identical looking swords - one of 1095 the other of 1045, they would weigh the same. 1045 is only more commonly used because cheaper swords tend to be made from it. Edit: No real swords are made from stainless steel.

- Q: What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including manual slitters, semi-automatic slitters, and fully automatic slitters. Manual slitters require manual adjustment and operation, while semi-automatic slitters have some automated features but still require some manual intervention. Fully automatic slitters are the most advanced type, with fully automated controls and high-speed operation.

Send your message to us

Matt Finish Cold Rolled Steel-JIS G3141 SPCC-2

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 4000吨 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords