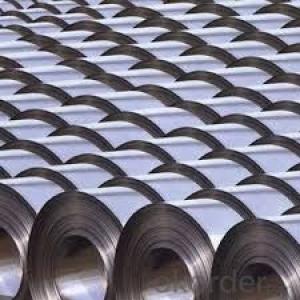

JIS G3131 SPHC Hot Rolled Steel Coil in hight quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot-rolling mill: Equipment on which solidified steel preheated to a high temperature is continuously rolled between two rotating cylinders.

These products are suitable for a wide range of applications, from formable quality to specific strength requirement in material.

SABIC can supply Hot Rolled Coils as Mill Edged, Side Trim Edged, Slit, Skin Passed, Chequered and Pickled Coils

Our Advantage:

High quality steel products from 1 class mills in China

Reasonable price

Professionalism of the products

On-time delivery

Complete documents and certificates

Sincere service to meet our clients' requirements

Standard and Grade :

JIS | ASTM | SAE | EN | |

Commercial quality | G3131 SPHC | A569 A635 A659 A1011 CS Type A,B,C | 1006~1025 |

10111 DD11 |

Drawing quality | G3131 SPHD | 1006~1010 | 10111 DD12 | |

Deep drawing quality | G3131 SPHE | A622 A1011 DS Type A,B | 1006~1010 | 10111 DD13 DD14 |

General structure (T.S.<490N/MM2) | G3101 SS330 SS440 G3106 SM400A G3132 SPHT1 SPTT2 SPHT3 | A36 A283 GR.C A570 GR.30~40 A1001 SS GR.30~40 |

1010~1025 | |

General structure (T.S.≥490N/MM2) | G3101 SS490 G3106 SM490A SM490YA | A570 GR.45~50 A607 GR.45~70 A1011 SS GR.45,50 |

J1392 050X |

|

Application :

Automobile Industry, electrical appliance, machinery manufacturing, container manufacturing, shipbuilding,

bridge, pipeline, and receive high acclaim from our customers for its excellent quality.

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | Within 30 days of receipt of LC original or prepayment |

- Q: I've created something but it's a huge secret. Anyways I need to know everything and anything about steel. Like the iron steel. ANYTHING AND EVERYTHING. Best answer goes to the person with the most correct information. Please this is really important.

- If you want to know everything about steel, there's no way you're going to get an answer on Yahoo that is comprehensive enough. What you want to do is get some books on steel metallurgy, engineering properties of materials, and maybe machine design depending on your application. Topics will include molecular structure, material properties, alloying, stress and strain, work hardening, creep, computing damage and lifetime cycles, corrosion, toughness vs hardness, heat treating, and a ton of others. If you want to sharpen steel, that is a whole topic in itself concerning different blade profiles and their sharpness, edge holding, ease of sharpening, type of grind etc.

- Q: i found a similar question asking what metals were in stainless steel but i don't know if they are the same.... they probably aren't.

- steel is iron with a little bit of carbon mixed in. how much carbon determines the hardness of the steel. stainless steel is the same mostly, it has nickle and chromium added in to make it corrosion resistant.

- Q: Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- This Site Might Help You. RE: what is the elastic limit of steel in Nm^2? Can't find it- this is for a physics experiment for youngs modulus done with a steel wire.

- Q: Could someone please explain what happens when steel is heat treated and why these happenings cause the steel to become harder? Please dig down into the micro details of the crystallites but in somewhat laymen's terms. Also describe the processes which achieve these results; if you have the time. Thanks for your time and effort.

- Alright, usually whu heat you heat treat mild steel, this is because you would like it stronger than you got it. To do this you must alter the grain structure of the part or in other words, the CRYSTALLITES. Ultimately you'll end up altering the nature of the grains structure changing the tensile strength it can handle, yield strength, and even change the elongation percentage that it can tolerate under load. Heat treatment controls the rate of diffusion, and the rate of cooling within the microstructure to create these elements. Usually what they use to do this is add an element to it to make it stronger such as carbon to increase its rockwell hardness, which by the way the lower you go the harder the part can become. Heat treatment can be used in more ways than this. It can also be used to weaken the parts grain structure. This will lower the parts mechanical properties making it softer and more ductile or easier to manipulate if you have to bend it into a particular shape. Typically if you allow the part to cool after heat treatment it does go through annealing. The part will be heat treated into different stages. The first being the austenitic crystal phase which depending on how hard and strong you want it, will be at its peak. When it is cooled, it will go through a will transform to martensite which is a hard yet brittle crystalline structure. Martenised part will usually be tempered to a certain degree to improve the mechanical properties to what is needed. There is more to this and you can use the link below to read more about it.

- Q: What is the process of uncoiling steel coils?

- The process of uncoiling steel coils involves carefully unwinding the tightly wound steel coil using specialized equipment. This typically includes a decoiler or uncoiler machine that holds and releases the coil, allowing it to gradually unwind. The coil is typically fed through a set of rollers or guides to ensure a smooth and controlled unwinding process. As the coil unwinds, it can be further processed or used for various applications, such as cutting, stamping, or forming into different shapes.

- Q: Hi all.I'm working on a project which requires about 3 steel pipes at 25mm in diametre and about a foot each in length.The qualities I need with the steel is that:1. I need it to be easy enough to weld together2. I need to be able to drill holes through them with a basic drill (I could buy different bits, that's fine)3. I need the steel to be able to take short intense repeated bursts of strain through said holes4. The lighter the steel the better5. Could I please have a ballpark figure for price. I can't imagine such a small amount of steel would cost too muchThank you in advance for your replyRegardsSean

- Call the steel pipe company or check their website

- Q: What are the common methods of painting or coating steel coils?

- Coil coating is a commonly used technique for painting or coating steel coils. It involves cleaning and pre-treating the coils to remove contaminants and enhance adhesion. Next, a primer or base coat is applied to establish a solid foundation. This primer safeguards the steel against corrosion and enhances the overall durability of the coating. Once the primer is applied, the steel coils undergo a series of rollers to apply the topcoat. The topcoat can consist of various materials such as polyester, polyurethane, or fluoropolymer, depending on the desired properties of the final coating. These topcoats provide the desired color, gloss, and protection against weathering, chemical exposure, and UV radiation. Electrostatic spraying is another popular method for painting or coating steel coils. It involves atomizing the paint or coating material into fine droplets and charging them with electricity. The grounded steel coils attract these charged droplets, resulting in a controlled and even application of the paint or coating material. Powder coating is yet another technique utilized for painting or coating steel coils. It involves electrostatically charging a dry powder and spraying it onto the steel coils. The charged powder adheres to the steel surface due to electrostatic attraction. The coated steel coils are then heated, causing the powder to melt and form a continuous film, resulting in a durable and resistant coating. In conclusion, these methods provide a wide range of options in terms of color, finish, and performance characteristics for painting or coating steel coils. The choice of method depends on factors such as desired appearance, level of protection required, and specific application requirements.

- Q: As we all know Shaq killed the movie Steel by suckin so bad but does anyone know what happened to the comic book version.

- The comic book has been long cancelled. You can see Steel in the ongoing 52 miniseries.

- Q: How are steel coils used in the manufacturing of HVAC systems?

- Steel coils are used in the manufacturing of HVAC systems as they serve as the primary heat transfer component. The coils are designed to efficiently transfer heat between the air and refrigerant, allowing for effective cooling or heating of the space.

- Q: How are steel coils used in the production of steel chains?

- Steel coils are used in the production of steel chains by being unwound and fed into a machine that shapes and forms the individual links of the chain. The steel coils provide the raw material needed to create the strong and durable chains, ensuring they have the necessary strength and integrity for various applications.

Send your message to us

JIS G3131 SPHC Hot Rolled Steel Coil in hight quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords