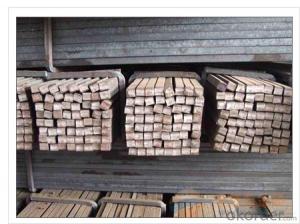

Hot Rolled Steel Square Bar with the Size 120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Square Bar can be used as steel billet for other steel products like steel angles, channels, I-beams, H-beams, steel Rebar, steel wire rod etc.

Feature:

We have two kinds of Hot Rolled Steel Square Bar which is used as billet, one is produced by blast furnace, the other is produced by electrical arc furnace. The prices are different.

Detail Sizes:

120*120mm 113.18kg/m

Material Grade:Q235 Q275 3SP 5SP

FAQ:

Packing Detail: The products can be packed naked,loose

The products can be delivered by bulk vessel or by container

Color mark: there will be color marking on both ends of the bundles for the cargo delivered by bulk vessel. That makes is easily to distinguish at the destination port.

Tag mark: the tag marks will be tied up to each bundle. The information is usually including supplier’s logo and name, product name, made in China, products’ specifications and other information requested by customers.

- Q: What are some common materials used in the construction of a steel square?

- Stainless steel, carbon steel, and aluminum are all frequently employed in the construction of a steel square. Stainless steel is favored for its durability, resistance to corrosion, and ability to withstand high temperatures. Similarly, carbon steel is often chosen for its strength and cost-effectiveness. Additionally, aluminum is utilized in the construction of steel squares due to its lightweight nature, which facilitates easier handling and transportation of the tool. These materials are carefully selected for their distinct properties, ensuring that the steel square remains dependable, precise, and enduring.

- Q: Can a steel square be used for checking the squareness of a power planer table?

- No, a steel square cannot be used for checking the squareness of a power planer table. A steel square is typically used for checking the squareness of corners or edges of materials, but it is not suitable for checking the squareness of a larger surface like a power planer table. To properly check the squareness of a power planer table, specialized tools such as precision straight edges or dial indicators are more appropriate. These tools allow for accurate measurements and ensure that the table is perfectly square, which is important for achieving precise and uniform planing results.

- Q: Can a steel square be used for checking the squareness of a concrete form?

- Indeed, the squareness of a concrete form can be checked by employing a steel square. In construction, steel squares are frequently employed to gauge and confirm right angles. It is crucial to guarantee that the steel square is appropriately aligned with the concrete form's edges when utilizing it. By positioning the steel square alongside the form's edges, one can verify the perfect squareness of the corners and make adjustments if needed. This practice aids in guaranteeing the precise shape of the concrete form prior to pouring the concrete, ultimately leading to a superior final product.

- Q: What are some common misconceptions about using a steel square?

- Addressing the misconceptions surrounding the use of a steel square is important as there are several that deserve clarification. Firstly, it is commonly believed that a steel square is solely intended for right angles. While it is indeed ideal for measuring and marking right angles, it can also be utilized for a wide range of other tasks. For instance, determining the pitch or slope of a roof, laying out stair stringers, and creating parallel lines are all possible with a steel square. Secondly, there is a misconception that using a steel square is challenging. Although it may appear daunting initially, with some practice, utilizing a steel square becomes second nature. Beginners can easily grasp the fundamentals of using a steel square through the abundance of resources available, including tutorials and videos. By dedicating time and effort to practicing, anyone can become proficient in employing this versatile tool. Furthermore, there exists a belief that a steel square is outdated, having been replaced by digital measuring devices. While it is true that technology has introduced a wide array of measuring tools, the steel square remains a reliable and accurate option. Its simplicity and durability make it a staple in various professional trades, such as carpentry and masonry. Additionally, it does not necessitate batteries or calibration, rendering it both cost-effective and dependable. Lastly, some individuals assume that a steel square is exclusively useful for professional builders or craftsmen. However, this is not the case. Whether you are a DIY enthusiast or a professional, incorporating a steel square into your toolbox can prove highly valuable. Its versatility and user-friendly nature make it an excellent tool for a diverse range of projects, ranging from simple woodworking to complex construction tasks. In conclusion, the misconceptions surrounding the use of a steel square need to be addressed. It is not limited to right angles, it is not difficult to use, it is not outdated, and it is not exclusively for professionals. By understanding and dispelling these misconceptions, individuals can truly appreciate the usefulness and versatility of this timeless tool.

- Q: What is the difference between a steel square and a framing square?

- Carpentry and construction benefit greatly from the use of a steel square and a framing square, yet they possess distinct characteristics. Referred to as a carpenter's square or framing square, a steel square is a versatile tool for measuring and marking. Constructed from steel, it consists of two arms, one longer and one shorter, joined at a right angle. The longer arm, known as the blade, and the shorter arm, known as the tongue, aid in accurate measurements and layout by featuring a range of measurements and markings along their edges. In contrast, a framing square, a particular type of steel square, finds its primary use in framing and layout work. Comprised of steel, it follows the same right-angle design as a standard steel square. However, its features cater specifically to framing tasks. Boasting a wider blade and tongue, it enables more precise and stable measurements and cuts. Frequently, the wider blade is graduated with measurements and markings tailored to framing, including rafter lengths, roof pitches, and stair layouts. To summarize, although both a steel square and a framing square consist of steel and adopt a right-angle design, a framing square distinguishes itself as a specialized steel square explicitly crafted for framing tasks. It possesses a broader blade and tongue and is often graduated with measurements and markings designed exclusively for framing endeavors.

- Q: Can a steel square be used for woodworking joinery?

- Yes, a steel square can certainly be used for woodworking joinery. While traditional woodworking squares are typically made of wood or plastic, a steel square can offer certain advantages. Steel squares are known for their durability and accuracy, making them a reliable tool for accurate measurements and ensuring precise joinery. They have a sturdy construction that maintains its shape over time, ensuring consistent and reliable results. When using a steel square for woodworking joinery, it is important to ensure that the square is properly calibrated and aligned before making any measurements or markings. This can be done by checking it against a known accurate reference or by using a combination square to verify its accuracy. Some woodworkers prefer using a steel square for joinery work because of its resistance to warping or damage that may occur with wooden or plastic squares. The steel square can withstand the pressure and rigors of woodworking tasks, making it a long-lasting and reliable tool in the workshop. However, it is worth noting that steel squares tend to be heavier than their wooden or plastic counterparts, which may affect their ease of use for some woodworkers. Additionally, steel squares may have sharp edges, so caution should be exercised when handling them to avoid injury or damaging the wood. In conclusion, while a steel square may not be the traditional choice for woodworking joinery, it can certainly be used effectively and accurately. Its durability, accuracy, and resistance to warping make it a suitable tool for woodworkers looking for a reliable and long-lasting square.

- Q: How do you use a steel square to lay out a jack rafter with unequal pitch?

- To use a steel square to lay out a jack rafter with unequal pitch, you would first determine the desired pitch for the rafter. Then, using the steel square, align the pivot point with the plumb line of the ridge board and the desired pitch line on the tongue. Next, mark the run of the rafter on the blade of the square. Finally, transfer the marked measurements onto the rafter board and cut accordingly to create the jack rafter with unequal pitch.

- Q: How do you use a steel square to mark a line perpendicular to a board edge at a specific distance?

- To achieve a line perpendicular to a board edge with a specific distance using a steel square, the following instructions should be followed: 1. Position the steel square against the board's edge, aligning one arm of the square with the edge. 2. Adjust the square until the other arm forms a 90-degree angle with the edge, indicating perpendicularity. 3. Securely hold the square against the board once it is appropriately aligned. 4. Determine the desired distance from the edge where the line should be marked. For instance, if a 6-inch gap is desired, employ a tape measure or ruler to measure 6 inches from the edge. 5. Employ a pencil or marking tool to make a mark on the board along the arm of the square that corresponds to the measured distance. 6. Continuously mark along the entire length of the board, ensuring that each mark is both perpendicular to the edge and at the exact measured distance. 7. Once all marks are made, employ a ruler or straight edge to connect them, thus forming a straight line. By adhering to these steps, it is possible to accurately mark a line perpendicular to a board edge at a specific distance using a steel square.

- Q: Can a steel square be used for marking out finger joints?

- Certainly! The utilization of a steel square for marking out finger joints is indeed possible. In the realm of woodworking and carpentry, a steel square is a tool of great versatility and precision. It boasts a 90-degree angle and a ruler positioned along its edge, rendering it an ideal instrument for delineating straight lines and angles. In order to achieve a proper fit, accuracy plays a pivotal role when crafting finger joints. By employing a steel square, one can skillfully designate the necessary lines and angles required to fabricate these joints, thereby enabling meticulous and immaculate cuts. It is worth noting, however, that finger joints necessitate meticulous measurements and layout. Thus, for optimal outcomes, it is recommended to employ either a specialized finger joint jig or a dado blade on a table saw.

- Q: How do you use a steel square to find the square footage of a roof?

- To use a steel square to find the square footage of a roof, you would need to measure the length and width of each roof section using the square's measurements. Multiply the length by the width for each section, and then sum up the individual areas to find the total square footage of the roof.

Send your message to us

Hot Rolled Steel Square Bar with the Size 120mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords