Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Description:

Hot rolled steel flat bar with enough thickness 10mm Chinese standard is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Hot rolled steel flat bar with enough thickness 10mm Chinese standard is usually made of structural steel and is used in construction and civil engineering. The hot rolled steel flat bar with enough thickness 10mm Chinese standard resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Hot rolled steel flat bar with enough thickness 10mm Chinese standard theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

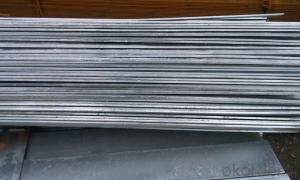

3. Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Images:

4. Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard Specification:

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: Can steel flat bars be threaded?

- Negative, threading is not possible for steel flat bars. Threading involves the creation of helical grooves on a material surface to enable the attachment of fasteners or other elements. Steel flat bars, as their name implies, possess a smooth surface and lack the essential characteristics required for threading. Nonetheless, in cases where threaded connections are necessary, alternative steel products like threaded rods or pipes can be employed.

- Q: Can steel flat bars be used for manufacturing kitchen equipment?

- Yes, steel flat bars can be used for manufacturing kitchen equipment. Steel is a strong and durable material that is commonly used in the manufacturing of kitchen equipment due to its resistance to corrosion, heat, and impact. Steel flat bars can be easily shaped and welded into various forms like countertops, shelves, or brackets, making them suitable for manufacturing different types of kitchen equipment.

- Q: Are steel flat bars suitable for making brackets or supports for recreational equipment?

- Yes, steel flat bars are suitable for making brackets or supports for recreational equipment. Steel is a strong and durable material, making it ideal for providing stability and support. Additionally, the flat shape of the bars allows for easy fabrication and installation of brackets or supports in various recreational equipment.

- Q: How do steel flat bars contribute to the energy efficiency of buildings?

- Steel flat bars can contribute to the energy efficiency of buildings in several ways. Firstly, steel is a highly durable material that can withstand extreme weather conditions, such as high winds and heavy rain, which can help in maintaining the structural integrity of the building over time. This durability leads to a longer lifespan for the building, reducing the need for frequent repairs or replacements, resulting in energy and cost savings. Additionally, steel flat bars are often used in the construction of windows and doors. These components play a crucial role in the energy efficiency of a building as they help to minimize heat transfer and air leakage. Steel, being a poor conductor of heat, can provide excellent insulation properties when used in window frames or door frames. This insulation helps to prevent heat loss during cold winter months and heat gain during hot summer months, reducing the reliance on heating or cooling systems and improving energy efficiency. Furthermore, steel flat bars can be used as structural elements in the building's envelope, such as in wall framing or roof trusses. The use of steel in these applications allows for the construction of lighter and stronger structures, which can facilitate the use of larger windows or open floor plans. This, in turn, promotes natural daylighting and ventilation, reducing the need for artificial lighting and mechanical ventilation systems. By maximizing the use of natural resources, steel flat bars contribute to the overall energy efficiency of the building. Lastly, steel is a recyclable material, meaning that after its use in a building, it can be easily recycled and repurposed for other applications. This promotes sustainable construction practices and reduces the overall environmental impact of the building industry. By choosing steel flat bars for construction, builders contribute to a circular economy, where materials are reused rather than disposed of, further enhancing the energy efficiency and sustainability of the building. In conclusion, steel flat bars contribute to the energy efficiency of buildings through their durability, insulation properties, structural benefits, and recyclability. By utilizing steel in various building components, builders can create more sustainable and energy-efficient structures, leading to long-term cost savings and reduced environmental impact.

- Q: Are steel flat bars suitable for making agricultural equipment?

- Indeed, steel flat bars prove to be a suitable material for the fabrication of agricultural equipment. Renowned for their durability, strength, and versatility, they are an ideal choice for a multitude of farming applications. Plows, cultivators, harrows, trailers, and livestock handling systems are just a few examples of the vast array of equipment that can be constructed using steel flat bars. The structural integrity of steel flat bars is exceptional, enabling them to endure the demanding conditions of heavy-duty use in agricultural settings. Their high tensile strength ensures that they remain resistant to bending and breaking, guaranteeing enduring performance. Furthermore, steel boasts remarkable resistance to corrosion, rendering it well-suited for outdoor applications and exposure to diverse weather conditions. Furthermore, steel flat bars can be effortlessly welded, cut, and shaped to fulfill specific design requirements, rendering them highly adaptable for the fabrication of custom agricultural equipment. The adaptability they offer allows for the creation of equipment that is tailored precisely to the unique needs and preferences of farmers. To summarize, steel flat bars are an unwavering and apt choice for the manufacture of agricultural equipment due to their durability, strength, versatility, and corrosion resistance.

- Q: Are steel flat bars prone to warping or twisting?

- Yes, steel flat bars are prone to warping or twisting due to their inherent properties and manufacturing processes. Factors such as uneven cooling, internal stresses, or improper handling can cause distortion in steel flat bars.

- Q: Can steel flat bars be used for manufacturing machinery?

- Certainly! Steel flat bars find extensive use in the manufacturing of machinery. They are highly adaptable and widely employed in various industries, including machinery production. These bars possess the qualities of strength, durability, and stability, rendering them ideal for the construction of machine frames, supports, brackets, and other vital components. Moreover, manufacturers can choose from a wide range of grades and sizes of steel flat bars to suit the specific requirements of the machinery being fabricated. In addition, these bars can be effortlessly machined and welded, allowing manufacturers to seamlessly customize and assemble machinery. On the whole, steel flat bars are a dependable choice for machinery manufacturing due to their mechanical properties and versatility.

- Q: What is the cost of steel flat bars?

- The cost of steel flat bars can vary depending on various factors such as the grade of steel, the size and thickness of the bars, and the quantity being purchased. Generally, the price range for steel flat bars can be anywhere from $10 to $50 per bar. However, it is important to note that these prices are just estimates and can vary significantly depending on the current market conditions and the specific suppliers. To get an accurate cost, it is recommended to contact local steel suppliers or check online marketplaces for the most up-to-date prices.

- Q: What are steel flat bars?

- Steel flat bars are long and rectangular pieces of steel that have a flat surface and straight edges. They are commonly used in construction, manufacturing, and fabrication industries for various applications such as supports, braces, framework, and reinforcement due to their strength and versatility.

- Q: Can steel flat bars be cut to length?

- Yes, steel flat bars can be cut to length. Steel flat bars are versatile and can be easily cut using various cutting tools such as saws, shears, or plasma cutters. The process of cutting steel flat bars to length is commonly done in fabrication shops or construction sites to meet specific project requirements. With the appropriate tools and techniques, steel flat bars can be accurately and cleanly cut to the desired length.

Send your message to us

Hot Rolled Steel Flat Bar with Enough Thickness 10mm Chinese Standard

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords