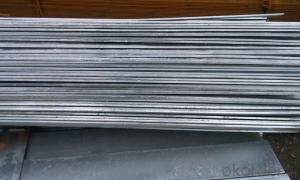

75x10 Flat Bar 50x10 Flat Bar 22mm/ Hot Rolled Flat Steel/ Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: Can steel flat bars be cold worked or hot worked?

- Steel flat bars can be both cold worked and hot worked, depending on the desired outcome. Cold working refers to the process of shaping or forming the steel at room temperature through techniques such as rolling, bending, or drawing. This method is commonly used to improve the strength and hardness of the steel, as well as to achieve precise dimensions and smooth surfaces. On the other hand, hot working involves shaping or forming the steel at elevated temperatures, typically above its recrystallization temperature. This process allows for greater plasticity and easier deformation of the steel. Hot working methods include forging, extrusion, and hot rolling. It is often used to produce complex shapes, reduce internal stresses, and enhance the material's grain structure. The choice between cold working and hot working steel flat bars depends on various factors, such as the desired mechanical properties, the complexity of the shape, and the equipment and resources available. Cold working is generally preferred for smaller-scale operations and when precise dimensions and surface finish are crucial. Hot working is more suitable for larger-scale production and when the steel needs to be shaped into intricate or complex forms.

- Q: What are the fire-resistance properties of steel flat bars?

- Steel flat bars have excellent fire-resistance properties. Due to their high melting point, steel bars can withstand high temperatures without losing their structural integrity. In the event of a fire, steel bars do not burn or contribute to the spread of flames, making them a reliable choice for fire-resistant structures. Additionally, steel bars have low thermal conductivity, meaning they do not easily transfer heat, further enhancing their fire-resistance. Overall, steel flat bars are highly resistant to fire and are widely used in construction projects where fire safety is a priority.

- Q: How do steel flat bars perform in terms of UV resistance?

- Steel flat bars lack inherent UV resistance properties, making them susceptible to negative effects when exposed to ultraviolet (UV) radiation from sunlight. Extended exposure to UV rays can cause degradation and brittleness in steel over time, resulting in discoloration, oxidation, and structural weaknesses in flat bars. To address these issues and enhance UV resistance, various methods can be utilized. One commonly employed approach involves applying protective coatings, such as paint or specialized finishes, to the steel surface. These coatings act as a barrier, shielding the steel from direct UV exposure and preventing degradation. Moreover, stainless steel flat bars tend to exhibit superior resistance to UV radiation compared to carbon steel. This is due to the presence of chromium in stainless steel, which forms a passive oxide layer offering some natural UV protection. However, it is important to note that even stainless steel can still be affected by intense UV rays when exposed for prolonged periods. Ultimately, when considering the use of steel flat bars in outdoor or UV-exposed applications, it is essential to carefully consider the specific environment, level of UV exposure, and the necessity for additional protective measures. These considerations are crucial for ensuring the longevity and performance of the steel flat bars.

- Q: What are the different grades of steel used in flat bars?

- There are several different grades of steel that are commonly used in flat bars, each with its own specific properties and applications. Some of the most common grades include: 1. Mild Steel (also known as low carbon steel): This is the most widely used grade of steel in flat bars. It has a relatively low carbon content, which makes it easy to work with and provides good weldability. Mild steel is commonly used in construction, automotive, and general fabrication applications. 2. Carbon Steel: This grade of steel has a higher carbon content than mild steel, typically ranging from 0.30% to 2.0%. Carbon steel offers increased strength and hardness compared to mild steel, making it suitable for applications that require higher load-bearing capabilities, such as machinery parts and structural components. 3. Alloy Steel: Alloy steel is a type of steel that contains additional elements such as manganese, silicon, nickel, chromium, or molybdenum. These alloying elements enhance the mechanical properties of the steel, including its strength, hardness, and corrosion resistance. Alloy steel flat bars are commonly used in the manufacturing of tools, gears, and machine parts. 4. Stainless Steel: Stainless steel is a corrosion-resistant grade of steel that contains a minimum of 10.5% chromium. It offers excellent resistance to rust, staining, and corrosion, making it ideal for applications in harsh environments or where hygiene is crucial, such as food processing, pharmaceuticals, and marine applications. Stainless steel flat bars are available in various grades, with the most common ones being 304 and 316. 5. Tool Steel: Tool steel is a specialized grade of steel that is designed to exhibit exceptional hardness, toughness, and wear resistance. It is commonly used in the manufacturing of cutting tools, molds, and dies. Tool steel flat bars are available in different grades, such as A2, D2, and O1, each offering specific properties suited for different applications. It's worth noting that these are just a few examples of the different grades of steel used in flat bars. There are many other specialized grades available for specific applications, such as heat-resistant steel, wear-resistant steel, and high-strength steel, among others. The choice of grade depends on the specific requirements of the application in terms of strength, corrosion resistance, hardness, and other properties.

- Q: Can steel flat bars be used in automotive manufacturing?

- Yes, steel flat bars can be used in automotive manufacturing. Steel flat bars are commonly used in various applications within the automotive industry due to their strength, durability, and versatility. They can be used in the fabrication of various automotive components, such as brackets, supports, frames, hinges, and reinforcements. Steel flat bars offer excellent structural integrity and can withstand heavy loads, making them suitable for use in automotive manufacturing. Additionally, steel is a cost-effective material and readily available, making it a popular choice in the automotive industry.

- Q: Can steel flat bars be used for manufacturing scaffolding or construction supports?

- Yes, steel flat bars can be used for manufacturing scaffolding or construction supports. They offer excellent strength and durability, making them suitable for such applications. Additionally, steel flat bars can be easily fabricated and welded to create the necessary shapes and structures required for scaffolding and construction supports.

- Q: Can steel flat bars be used for making telecommunications industry equipment?

- Yes, steel flat bars can be used for making telecommunications industry equipment. Steel is a commonly used material in the manufacturing of various equipment due to its strength, durability, and cost-effectiveness. Steel flat bars can be used in the construction of equipment racks, supports, brackets, and frames for housing telecommunications equipment such as servers, switches, routers, and antennas. The flat shape of the bars allows for easy fabrication and customization to meet specific design requirements. Additionally, steel is resistant to corrosion, which is crucial for telecommunications equipment that may be exposed to harsh environmental conditions. Overall, steel flat bars are a suitable choice for constructing telecommunications industry equipment.

- Q: What is the difference between flat steel and steel sheet material?

- It is a kind of flat steel, flat steel plate is mainly used for general structure, construction, general machinery parts; and the steel plate is including carbon steel, alloy steel, high performance steel structure, this kind of material is.

- Q: What is the typical length of a steel flat bar?

- The typical length of a steel flat bar can vary, but it is commonly available in lengths ranging from 6 to 20 feet.

- Q: Can steel flat bars be used for architectural designs?

- Without a doubt, steel flat bars are a fantastic option for incorporating into architectural designs. With their versatility and durability, these bars are well-suited for a wide array of architectural applications. They possess the capability to serve multiple purposes, including providing structural support, acting as decorative elements, and serving as cladding. The ease with which steel flat bars can be fabricated and molded into various shapes and sizes allows for the creation of innovative and one-of-a-kind architectural designs. Furthermore, steel's reputation for strength and longevity makes it the perfect choice for architectural projects that demand resilience and durability. In conclusion, architects and designers frequently opt for steel flat bars due to their practicality, aesthetics, and capacity to enhance a structure's overall design.

Send your message to us

75x10 Flat Bar 50x10 Flat Bar 22mm/ Hot Rolled Flat Steel/ Steel Flat Bar

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 23000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords