Hot Rolled Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

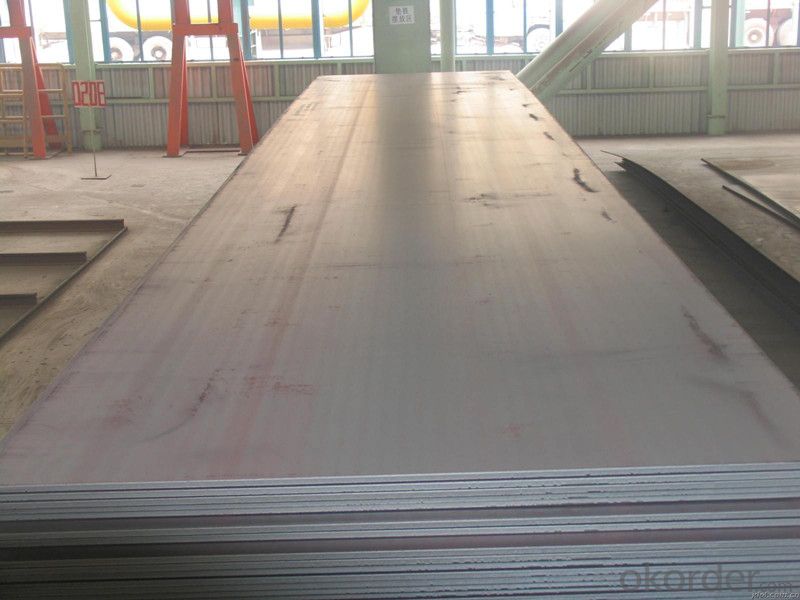

Standard Hot Rolled Steel Sheets/Coils

OKorder is offering high quality Standard Hot Rolled Steel. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Standard Hot Rolled Steel are used for floor board, factory stair boards, deck board, car boards ,staircases, lorry beds, elevator floors, general fabrication.

Fridge ,air conditioner, washing machine and household appliances, automobile,steel furniture, drum, motorcycles, fitting apparatuses, furniturem,builings electronic telecoms and gas- conveyance projects.

Product Advantages:

OKorder's Hot rolled steel are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Brand: HBIS,Shagang,Ansteel,Baosteel

Grade: Q195 Q225 Q235 Q345 A36 S235jr St37-2 SS400

Thickness: 1.2mm and above

Width: 750mm-2000mm

FAQ:

1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Images:

- Q: I want to make an object out of stainless steel. Initially, I had planned to get it cut out of stainless steel sheet but several of the edges need to be rounded and I think it would be much cheaper to get it made of cast iron formed in a mold.Yet, it must be stainless steel. Can stainless steel be formed in a mold like iron can ... i.e. poured in liquid form into a mold and harden into shiny stainless steel?Would a regular foundry do this or do I need something special?Thanks.

- You have 2 options. Sand casting or investment casting. Stainless steel can be cast with either of these methods. In either case a model or pattern will have to be created. For sand casting the pattern is all that is needed to go to casting. For investment casting the pattern is used to make a wax casting, which is then coated with the investment. The wax is burned out and the metal is then poured into the cavity. If you are making just 1 or 2 pieces you can have waxes machined. This saves the intermediate step Depending on the size machining may still be your best option. Especially if you want just 1 part.

- Q: i wanna know all the similarities between iron and steel

- Iron is raw from iron ore, steel has other metals added such as alloys or copper to give tesil strength and flexibility

- Q: What are the different methods of edge trimming steel coils?

- There are several methods for edge trimming steel coils, including shearing, slitting, laser cutting, and milling. Each method has its own advantages and is chosen based on factors such as the desired precision, speed, and cost-effectiveness of the trimming process.

- Q: What are the common storage defects in steel coils?

- Common storage defects in steel coils include corrosion, rusting, surface damage (such as scratches or dents), coil slippage or misalignment, coil edge damage, and moisture or water damage. These defects can occur due to improper storage conditions, handling, or exposure to environmental factors. Regular inspection and proper storage practices are essential to prevent these defects and maintain the quality of steel coils.

- Q: I need to construct a table with three columns, which states the name of the steel, its compositions (e.g. Fe and C), and its special properties for a variety of different steel products.Help me please, a site with info would be great, explanations would be even better.

- Steel is an alloy consisting mostly of iron, with a carbon content between 0.2% and 2.1% by weight, depending on the grade. Carbon is the most common alloying material for iron, but various other alloying elements are used, such as manganese, chromium, vanadium, and tungsten.[1] Carbon and other elements act as a hardening agent, preventing dislocations in the iron atom crystal lattice from sliding past one another. Varying the amount of alloying elements and form of their presence in the steel (solute elements, precipitated phase) controls qualities such as the hardness, ductility, and tensile strength of the resulting steel. Steel with increased carbon content can be made harder and stronger than iron, but is also less ductile. H.

- Q: Is there any way to melt steel without the intense heat of a blast furnace?

- Iron melts at a very high temperature, so if the goal is to melt it, then there will be a certain amount of intense heat of course. Steel is recycled in a carbon arc furnace. The bottom is lined in graphite. Large graphite rods are lowered into iron scrap and enormous amounts of electricity melt the iron due to the heating of the carbon due to its resistance. The carbon also removes any oxides by forming CO2. Aluminum and lead can also be recycled in this fashion. Ordinary rust can be turned into liquid iron through the use of the thermite reaction. Rust and aluminum power can be ignited with a propane toarch or a magnesium ribbon fuse. The aluminum is oxidized and the rust reduced to molten iron. This reaction is used to spot weld cracks in steel structures, like railroad tracks. It is also a popular arson device used by spies.

- Q: hi i was doing a little history project on guns. i was just wondering if anyone could help me find out what material was used before steel and why this material wasnt as good as steel ( its faults)thanks for your help

- Gunmetal is a specific type of brass

- Q: The knife will be large and thick. Like the Bowie knife Rambo uses in Rambo III. It doesn't need to be flexible or to hold the edge very well. But i need it to be exceptionally strong material and to stop corrosion at least decently. Is Damascus Steel good?Thank you, in advance.

- Damascus steel is the poorest quality. The laminations separate under stress. Centuries ago the only way to get steel bars was to make it up by hammering wires together in a series of welds. The welds usually were porous and the steel would fail. The pattern of the welds is attractive to some people. An old file has good hard steel and wiill make up into a knife if it is annealed to make it easier to shape and cut. The hardness can be restored by tempering. Treating with oil is the cure to prevent rust.

- Q: How are steel coils used in the manufacturing of renewable energy equipment?

- Steel coils are used in the manufacturing of renewable energy equipment as they serve as a crucial component for structural support and durability. These coils are often used to construct the frames and structures of wind turbines, solar panels, and other renewable energy equipment. Additionally, steel coils are used for the production of electrical transformers and generators, which are vital for converting renewable energy sources into usable electricity.

- Q: I'm looking to get a track bike/ fixie to ride around the city of Chicago. I've looked at many bikes and they're mostly made out of Hi Ten steel. My old fixie (which was stolen at North Ave Beach) was made out of aluminum (KHS FLITE 100). How big of a difference is it between aluminum and steel? I know steel is heavier but how does it effect the ride? Is a aluminum bike or a steel bike better to get to ride around the bike path and in the city of Chicago?

- A steel frame would weigh at most 2 pounds more than an aluminum frame. That would be comparing a less expensive steel frame to a really good aluminum frame. However if you are talking about comparable prices the weight difference would be much less, about 1 pound

Send your message to us

Hot Rolled Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords