Hot-dipped Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

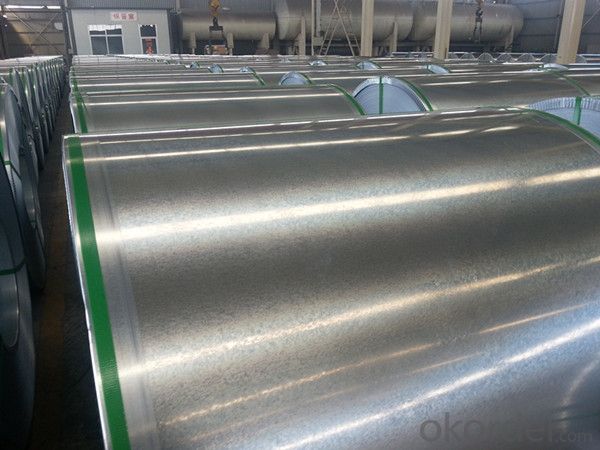

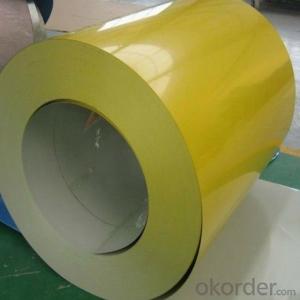

OKorder is offering high quality Cold rolled Hot Dip Galvanized Steel Coil at great prices with worldwide shipping. Our supplier is a world-class manufacturer of galvanized steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

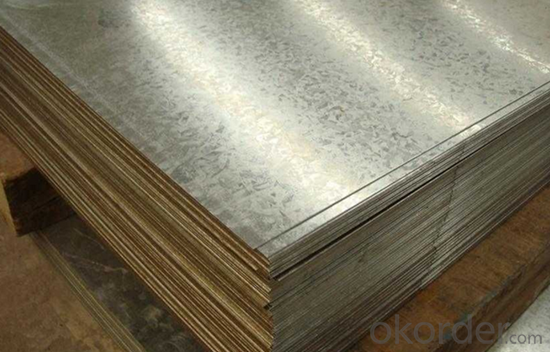

Cold rolled Hot Dip Galvanized Steel Coil is ideal for fabricating and manufacturing applications.

Product Advantages:

OKorder's Galvanized Steel Coil is durable, boasts high stiffness and load-bearing qualities, and is recyclable.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Coil ID: 508mm

Coil OD: 900-1500 mm

Grade: DX51D+Z

Coating: 30 – 180g/m² (both sides)

Dimensions:

Thickness: 0.2mm – 1.0mm

Width: 600mm, 914mm, 1000mm, 1220mm, 1250mm

Coil Weight: 4 – 6mt

Length: 6m, 9m, 12m

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

Q5: Can stainless steel rust?

A5: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

Q6: What is the difference between galvanized steel and Galvalume steel?

A6: Galvanized steel is metallic coated with Zinc in various coating weights. Minimum recommended for painted metal roofs is G90. Galvalume is a zinc and aluminum coated steel that becomes an alloy and is recommended in either painted or bare applications with a minimum coating weight of AZ50. Galvalume has an excellent performance life in bare exposures. Hence if you are using a bare panel use Galvalume and if painted use either.

Images:

- Q: Measures to prevent cold rolling of packaged cold rolled steel coils? Who can give some professional opinions oh?

- Cold rolled steel coils are generally sprayed antirust oil, according to user requirements, light, medium, heavy oil 3 types. Nevertheless, if the oil is volatile or in a humid environment, the steel plate comes into contact with the water for a period of time, indicating that it is beginning to rust.

- Q: what do you think about it? Is it a good steel for the money? the knife that i have with that steel is the kershaw chill. good knife for the price

- 8Cr13MoV is a decent blade steel...not a great steel, but about as good as you will generally find without paying much higher prices. It's used by a number of well known knife makers... It's basically equivalent to AUS-8 and will work and hold an edge reasonably well for most basic cutting chores. *************************************** From Wikipedia, the free encyclopedia: 8Cr13MoV, a Chinese stainless steel tempered at the Rc56 to Rc58 range and used in the Tenacious, Persistence, Ambitious, Resilience, Grasshopper, Kiwi3 and Byrd lines of knives. Often compared to AUS-8, but with slightly more Carbon.

- Q: What are the different types of steel coil edge trimming methods?

- There are several different methods used to trim the edges of steel coils, including slitting, shearing, and laser cutting. Slitting involves using circular blades to cut the edges of the coil, creating narrower strips. Shearing is a process that uses a straight blade to cut the coil edges. Laser cutting is a more advanced method that uses a laser beam to precisely trim the edges of the steel coil. These methods are used depending on the specific requirements of the steel coil and the desired end product.

- Q: What are the challenges in coil slitting for narrow strip widths?

- There are several challenges associated with coil slitting for narrow strip widths. One of the main challenges is maintaining accuracy and precision during the slitting process. When dealing with narrow strip widths, even the slightest misalignment or deviation can result in significant defects or inconsistencies in the final product. This requires careful calibration and adjustment of the slitting equipment to ensure that the strips are cut with utmost accuracy. Another challenge is the risk of material damage or deformation during the slitting process. Narrow strip widths are more prone to distortion, wrinkling, or edge cracking, especially if the material is not properly handled or supported during slitting. Special care must be taken to ensure that the material is fed smoothly through the slitting machine and that the tension is properly controlled to minimize any potential damage. Additionally, narrow strip widths can pose challenges in terms of handling and transporting the slit coils. These coils are more susceptible to bending, twisting, or telescoping, which can lead to difficulties in stacking, storage, or transportation. Proper packaging and handling techniques must be employed to ensure that the slit coils maintain their shape and integrity throughout the supply chain. Furthermore, narrow strip widths often require more frequent blade changes during the slitting process. This increases the complexity and time required for setup and maintenance, as the blades need to be carefully selected and replaced to achieve optimal cutting results. It is crucial to have skilled technicians who can handle these blade changes efficiently and effectively. Overall, while coil slitting for narrow strip widths offers various benefits such as cost savings and increased material utilization, it also presents several challenges that need to be carefully addressed. These challenges include maintaining accuracy, preventing material damage, ensuring proper handling and transportation, and managing blade changes effectively. By understanding and addressing these challenges, manufacturers can optimize their coil slitting operations and produce high-quality narrow strip products.

- Q: I asked a question last week about stainless steel and got some great answers. I combed all over the internet to try to figure this one out but could not find anything. What resists bending better: chrome vanadium steel (i.e. a steel commonly used to make tools) or stainless steel 304. My guess would be the chrome vanadium alloy but thats just a guess. Which on resist's bending better and by how much (#'s please :-)). Also, if anyone knows if chrome vanadium steel is cheaper than stainless steel 304 that would be awesome? I can't find a price per pound on chrome vanadium steel anywhere! Please help. Thanks in advance-Josh

- Steel Bending Strength

- Q: How are steel coils used in the production of agricultural implements?

- Steel coils are used in the production of agricultural implements by being transformed into various components such as blades, plows, and harrows. These components are then incorporated into the implements, enabling them to till the soil, plant seeds, and perform other tasks necessary for agricultural operations.

- Q: Can steel coils be used in the manufacturing of machinery and equipment?

- Machinery and equipment manufacturing can indeed utilize steel coils effectively. These coils possess remarkable versatility and contribute strength, durability, and stability to various industrial applications. They can be manipulated to assume various shapes, receive cuts, and undergo formation to generate diverse parts and components that are indispensable to the manufacturing process of machinery and equipment. Gears, shafts, frames, brackets, and other structural elements are commonly produced using steel coils. Moreover, these coils can undergo further processing to fashion specialized components like springs or fasteners. By incorporating steel coils into machinery and equipment manufacturing, the end products are guaranteed to possess exceptional quality, capable of enduring heavy loads, and boasting an extended lifespan.

- Q: How are steel coils used in the production of scaffolding?

- Steel coils are used in the production of scaffolding as they are typically cut and shaped into various components such as tubes, frames, and brackets. These coils provide the necessary strength and durability required for scaffolding structures, ensuring the safety and stability of workers who use them.

- Q: How are steel coils used in the production of steel screws?

- Steel coils are used in the production of steel screws as they serve as the raw material for manufacturing the screws. The steel coils are unwound and fed into a machine that cuts and shapes the steel into the desired screw form. This process ensures that the screws are made from high-quality steel and have the necessary strength and durability.

- Q: How do steel coils contribute to energy efficiency?

- Steel coils contribute to energy efficiency in several ways. Firstly, steel coils are lightweight and can be easily transported, reducing the energy required for transportation. Additionally, steel coils have high strength-to-weight ratio, allowing for efficient use of materials in construction, which reduces overall energy consumption. Furthermore, steel coils have excellent thermal conductivity, enabling efficient heat transfer and distribution in various applications, including heating and cooling systems. Lastly, steel is a highly recyclable material, and using steel coils promotes the circular economy and reduces the need for energy-intensive production processes.

Send your message to us

Hot-dipped Galvanized Steel Coils/Sheets from China CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords