Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Flat Steel Bars SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Flat Steel Bars SS400 are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Flat Steel Bars SS400 are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SS400

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Origin place: China

Thickness: 3mm-30mm

Width:20mm-200mm

Length: Max 12m

Certification: SGS/BV

Chemical composition of Q235

Alloy No | Grade | Element(%) | ||||

C

| Mn

| S

| P

| Si

| ||

Q235

|

B

|

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045

|

≤0.3

|

Physical properties of Q235

Alloy No | Grade | Yielding strength point(Mpa) | Tensile strength (Mpa) | Elongation after fracture(%) | ||||||

Thickness (mm) | Thickness (mm) | |||||||||

≤16 | >16--40 | >40--60 | >60--100 | ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | ≥ | |||||||||

Q235 |

B |

235 |

225 |

215 |

205 |

375--500 |

26 |

25 |

24 |

23 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What’s the Processes Flow of Flat Steel Bars?

A3:The steel flat bar is made through three processes:

1.Feeding the material: Feeding the row material (the steel plate) to Slitting Line.

2.Slitting:The steel plate would be slitted into expected width by lengthways cutter.

3. Leveled and cutting: The plat bar would be ground into level by the grinder and then cut into required length.

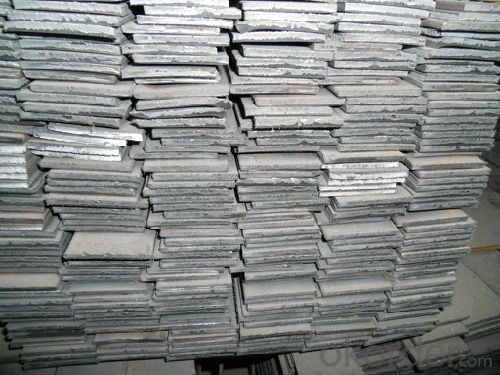

Images:

- Q: Can steel flat bars be heat treated?

- Yes, steel flat bars can be heat treated. Heat treatment is a process used to alter the mechanical and physical properties of steel, such as increasing its hardness or improving its strength. Heat treating steel flat bars involves heating the material to a specific temperature range and then cooling it rapidly or slowly, depending on the desired outcome. This process can enhance the flat bars' strength, toughness, and wear resistance.

- Q: What are the different surface defects that can occur in steel flat bars?

- There are several different surface defects that can occur in steel flat bars. These defects can arise during the manufacturing process or as a result of external factors. Some of the common surface defects include: 1. Scale: Scale refers to the oxide layer that forms on the surface of steel during the hot rolling process. It appears as a flaky, rough, or scaly surface and can affect the appearance and smoothness of the flat bar. 2. Surface cracks: Cracks can occur on the surface of steel flat bars due to various reasons such as excessive cooling, improper handling, or manufacturing defects. These cracks can vary in size and depth, and they can negatively impact the structural integrity of the steel. 3. Pitting: Pitting refers to the formation of small depressions or cavities on the surface of steel. It occurs due to localized corrosion, usually caused by exposure to corrosive environments or improper storage conditions. Pitting can lead to reduced strength and durability of the flat bar. 4. Roll marks: Roll marks are impressions or patterns left on the surface of steel flat bars during the rolling process. These marks are typically caused by irregularities or imperfections on the rolling mill rolls. Roll marks can affect the aesthetics and surface quality of the flat bar. 5. Surface roughness: Surface roughness refers to irregularities or unevenness on the surface of steel flat bars. It can occur due to inadequate cleaning or finishing processes, improper handling, or wear and tear during transportation. High surface roughness can impact the appearance and functionality of the flat bar, especially in applications where smoothness is crucial. 6. Surface contamination: Steel flat bars can be susceptible to various forms of surface contamination, such as dirt, oil, grease, or other foreign particles. Contamination can occur during manufacturing, handling, or storage. These contaminants can affect the surface quality and may also lead to corrosion or other performance issues. It is important to note that surface defects can vary in severity, and their impact on the flat bar's performance and suitability for specific applications can differ. Regular inspection, quality control measures, and proper handling and storage practices can help minimize the occurrence and impact of these surface defects in steel flat bars.

- Q: Earthing flat steel and earthing main line

- The flat steel is connected to the ground system, and the grounded line is connected to the protected equipment

- Q: What is the difference between a steel flat bar and a steel hex bar?

- The primary distinction between a steel flat bar and a steel hex bar lies in their shape and design. A steel flat bar, as its name implies, is a lengthy bar with a rectangular shape and a flat surface on all sides. It possesses a consistent thickness throughout its length and is typically utilized for structural functions, such as supports, braces, and framing. The flat surface facilitates easy fastening or welding to other components. Conversely, a steel hex bar is a bar with six equal sides, forming a hexagonal shape. This unique design offers enhanced strength and stability compared to a flat bar. The hexagonal shape also provides superior grip and torque resistance, rendering it suitable for applications that necessitate high tensile strength, such as machinery, tools, and hardware components. Regarding versatility, a steel flat bar can be easily manipulated, cut, or bent to accommodate various shapes and sizes, making it a more flexible choice for diverse projects. In contrast, a steel hex bar is more rigid and less malleable due to its six-sided structure, limiting its adaptability but augmenting its strength. In conclusion, though both steel flat bars and steel hex bars are crafted from the same material, their distinct shapes and designs render them appropriate for different applications. The flat bar is commonly employed for structural purposes, whereas the hex bar is favored for applications necessitating higher strength and torque resistance.

- Q: Can steel flat bars be polished?

- Yes, steel flat bars can be polished. Polishing steel flat bars involves using abrasive materials such as sandpaper or polishing compounds to remove any imperfections or roughness on the surface of the bars. The process typically involves gradually working through different grits of sandpaper or using a polishing wheel with a polishing compound to achieve a smooth and shiny finish. Polishing steel flat bars can enhance their appearance and make them more aesthetically pleasing.

- Q: Are steel flat bars used in the construction of bridges?

- Yes, steel flat bars are commonly used in the construction of bridges. Flat bars, also known as flat steel, are often utilized as structural components in bridge construction due to their strength, durability, and versatility. These bars are typically made from carbon steel, which provides the required strength to support the weight and load of the bridge. Steel flat bars are used in various bridge components, including beams, trusses, and decking. They are often incorporated into the structural framework to distribute the load and provide stability, ensuring the bridge's overall integrity. Additionally, steel flat bars are highly resistant to corrosion, making them suitable for outdoor applications where bridges are exposed to environmental elements. Overall, steel flat bars play a crucial role in the construction of bridges, contributing to their strength, stability, and longevity.

- Q: Can steel flat bars be used for automotive applications?

- Yes, steel flat bars can be used for automotive applications. They are commonly used in the manufacturing of various parts, such as brackets, supports, and frames, due to their strength, durability, and versatility.

- Q: What are the different types of tests performed on steel flat bars?

- There are several types of tests that are commonly performed on steel flat bars to ensure their quality and suitability for various applications. These tests aim to assess the strength, durability, and other mechanical properties of the steel. Some of the different types of tests performed on steel flat bars include: 1. Tensile Test: This test measures the maximum amount of tensile stress that a steel flat bar can withstand before it fractures. It helps determine the yield strength, ultimate tensile strength, and elongation of the material. 2. Hardness Test: The hardness of a steel flat bar is an important characteristic to determine its resistance to deformation, wear, and abrasion. Various methods such as Rockwell, Brinell, and Vickers hardness tests are used to measure the hardness of the steel. 3. Impact Test: This test helps evaluate the ability of the steel flat bar to absorb energy under high-stress conditions. It involves striking the material with a pendulum to measure the amount of energy absorbed and its ability to resist cracking or breaking. 4. Bend Test: The bend test assesses the ductility and flexibility of the steel flat bar by bending it to a specified angle without fracture. It helps determine if the material is suitable for applications that involve bending or forming processes. 5. Chemical Analysis: Chemical analysis is performed to determine the composition of the steel flat bar, including the percentage of various elements such as carbon, manganese, silicon, and others. This analysis ensures that the steel meets the required specifications and standards. 6. Ultrasonic Testing: Ultrasonic testing uses high-frequency sound waves to detect internal flaws or defects in the steel flat bar. It helps identify cracks, voids, or inclusions that may affect the overall integrity and strength of the material. 7. Dimensional Inspection: This test ensures that the steel flat bar meets the required dimensional tolerances and specifications. It involves measuring the length, width, thickness, and other dimensions of the bar to ensure it meets the desired standards. 8. Microstructure Analysis: Microstructure analysis involves examining the metallurgical structure of the steel flat bar under a microscope. It helps identify the grain size, phase distribution, and any abnormalities that may affect the material's mechanical properties. By performing these various tests, manufacturers, suppliers, and end-users can ensure that steel flat bars meet the necessary quality standards and are suitable for their intended applications.

- Q: Are steel flat bars resistant to heat?

- Steel flat bars generally have good resistance to heat. The exact level of resistance will depend on the specific type of steel used and its composition. Heat resistance is often measured by the material's ability to retain its strength and structural integrity under elevated temperatures. Steel is known for its high melting point, making it less susceptible to deformation or structural failure when exposed to heat. However, it is important to note that extreme temperatures, such as those encountered in a furnace or during prolonged exposure to high heat, can still cause some degree of thermal expansion or weakening of the steel. Therefore, while steel flat bars can generally withstand moderate heat, it is crucial to consider the specific application and potential temperature extremes when determining their suitability for a particular heat-related purpose.

- Q: What are the standard tolerances for straightness in steel flat bars?

- The standard tolerances for straightness in steel flat bars vary depending on the specific industry and application. However, in general, the standard tolerances for straightness in steel flat bars are typically defined by the American Society for Testing and Materials (ASTM) or the International Organization for Standardization (ISO). For example, according to ASTM A6/A6M, which covers general requirements for rolled structural steel bars, plates, shapes, and sheet piling, the maximum deviation from straightness for steel flat bars should not exceed 1/8 inch per 5 feet. This means that for every 5 feet in length, the steel flat bar can deviate from a perfectly straight line by no more than 1/8 inch. ISO 9444-1, which provides the tolerances on dimensions and form for continuously cold-rolled stainless steel narrow strip, also specifies tolerances for straightness. According to this standard, the maximum deviation from straightness for steel flat bars should not exceed 0.2% of the total length. This means that for a 10-foot long steel flat bar, the maximum deviation from straightness should not exceed 0.02 feet or approximately 0.24 inches. It is important to note that these are just a few examples of the standard tolerances for straightness in steel flat bars. Different industries, applications, and specifications may have their own specific tolerances that need to be adhered to. Therefore, it is always recommended to consult the relevant standards or specifications applicable to the specific use case to determine the appropriate tolerances for straightness in steel flat bars.

Send your message to us

Hot Rolled Flat Steel Bars SS400

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords