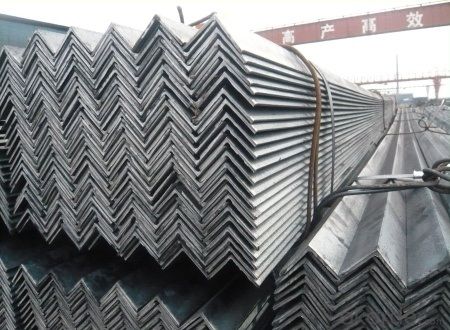

Hot Rolled Steel Angle Bar with High Quality 30*30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Specifications of Equal Angle Steel

1.Standards:GB

2.Length:6m, 12m

3.Material:GBQ235 or Equivalent

4. Size:

Size (mm) | Mass (mm) | Size (mm) | Mass (mm) |

| 30*30*5 | 2.184 | 38*38*2.5 | 1.482 |

| 30*30*6 | 2.564 | 38*38*3 | 1.758 |

Usage & Applications of Equal Anlge Steel

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery of Equal Angle Steel

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 30 to 45 days from the beginning of production.

Images:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: What is the maximum allowable tensile stress for a steel angle?

- The maximum allowable tensile stress for a steel angle depends on various factors such as the specific grade of steel, the manufacturing process, and the intended application. Steel angles are commonly used in construction and structural applications, and their maximum allowable tensile stress is typically determined by industry standards and design codes. For example, in the United States, the American Institute of Steel Construction (AISC) provides design specifications for structural steel angles. According to AISC, the maximum allowable tensile stress for a steel angle is typically based on the yield strength of the steel material. The yield strength refers to the stress at which a material begins to deform permanently. It is usually specified in terms of pounds per square inch (psi) or megapascals (MPa). Steel angles are typically designed to operate within a certain percentage of their yield strength to ensure structural integrity and safety. In general, the maximum allowable tensile stress for a steel angle is often limited to a percentage of its yield strength, typically ranging from 50% to 70%. This means that the maximum tensile stress that can be applied to a steel angle is a fraction of its yield strength. It is crucial to consult the appropriate design standards and codes, such as those provided by AISC or other relevant organizations, to determine the specific maximum allowable tensile stress for a given steel angle in a particular application. These standards consider factors such as load conditions, safety factors, and environmental conditions to ensure the structural integrity and reliability of the steel angle.

- Q: What are the different types of connections for steel angles?

- There are several different types of connections for steel angles, including bolted connections, welded connections, and clip connections. Bolted connections involve using bolts and nuts to secure the angles together, while welded connections are created by melting the edges of the angles together. Clip connections use specially designed clips to hold the angles in place without the need for welding or bolting. Each type of connection has its own advantages and disadvantages, and the choice of connection method depends on factors such as the load-bearing requirements, ease of installation, and cost.

- Q: Can steel angles be used to create decorative elements in architecture?

- Yes, steel angles can definitely be used to create decorative elements in architecture. Steel angles, also known as angle irons, are versatile and can be easily manipulated to create various shapes and designs. They can be cut, bent, and welded to form intricate patterns, ornamental details, and decorative accents. Steel angles can be used in various architectural applications, such as railings, balusters, window grilles, door frames, brackets, and ornamental trims. Their strength and durability make them suitable for both indoor and outdoor use. They can be finished with different coatings, such as paint or powder coating, to enhance their appearance and protect them from corrosion. Architects and designers often incorporate steel angles in modern and contemporary designs to add an industrial, sleek, and minimalist touch. The clean lines and geometric shapes of steel angles can provide a modern aesthetic to buildings and structures. They can be used to create unique and eye-catching patterns, adding visual interest and a sense of style to architectural projects. Moreover, steel angles can also be combined with other materials, such as glass, wood, or stone, to create a striking contrast and achieve a harmonious blend of materials. This versatility allows for endless design possibilities, enabling architects to create truly customized and distinctive decorative elements. In conclusion, steel angles can be effectively used to create decorative elements in architecture. Their versatility, strength, and potential for customization make them an ideal choice for architects and designers looking to add aesthetic appeal and uniqueness to their projects.

- Q: How do steel angles perform under wind loads?

- Steel angles are commonly used in construction to provide structural support and stability. When it comes to wind loads, steel angles have proven to be highly reliable and effective. The shape and design of steel angles allow them to withstand the force exerted by wind, preventing any significant deformation or failure. Under wind loads, steel angles distribute the force evenly along their length, transferring it to other connected structural members. This helps to minimize the potential for localized stress concentrations and ensures the overall stability of the structure. Steel angles also have high strength and stiffness, making them capable of resisting the bending and twisting forces caused by wind. This is especially important in areas prone to high wind speeds or in tall buildings where wind loads can be more significant. The rigidity of steel angles helps maintain the integrity of the structure and prevents excessive deflection or deformation. Moreover, steel angles can be easily connected to other structural components using various methods such as welding, bolting, or riveting. This allows for a secure and reliable connection that can withstand the wind loads without compromising the overall strength and stability of the structure. In summary, steel angles perform exceptionally well under wind loads due to their shape, strength, and rigidity. They effectively distribute the wind forces and maintain the structural stability, making them a reliable choice for construction projects in areas prone to wind or for structures that need to withstand significant wind loads.

- Q: Are there any limitations on the angle of inclination for steel angles?

- Yes, there are limitations on the angle of inclination for steel angles. The maximum angle of inclination primarily depends on the structural design and purpose of the steel angle. In general, steel angles are designed to withstand vertical and horizontal loads, but excessive angle of inclination can compromise their structural integrity. Design codes and engineering standards provide guidelines for determining the maximum allowable angle of inclination based on factors such as the material properties, applied loads, and safety factors.

- Q: How do steel angles contribute to the sustainability of a city?

- Steel angles contribute to the sustainability of a city in several ways. Firstly, steel angles are a crucial component in the construction industry, used in the fabrication of buildings, bridges, and other infrastructure. Steel is known for its strength, durability, and resistance to external factors such as corrosion and fire. By using steel angles in construction projects, cities can ensure the longevity and safety of their structures, reducing the need for frequent maintenance or replacement. This leads to a significant reduction in the consumption of resources over time, making cities more sustainable. Additionally, steel angles offer design flexibility, allowing architects and engineers to create innovative and efficient structures. Their versatility enables the construction of sustainable buildings that incorporate features such as energy-efficient designs, natural lighting, and effective insulation. By utilizing steel angles in the construction process, cities can promote sustainable practices and reduce energy consumption, contributing to a more sustainable urban environment. Furthermore, steel is a highly recyclable material, with a recycling rate of around 90%. By using steel angles in construction, cities can contribute to a circular economy by promoting the recycling and reuse of steel products. This reduces the demand for raw materials and minimizes waste, thereby reducing the environmental impact of construction projects. The use of recycled steel also helps to conserve energy and reduce greenhouse gas emissions associated with the production of new steel. In conclusion, steel angles play a vital role in the sustainability of a city by providing durable and long-lasting structures, enabling energy-efficient designs, and promoting the recycling and reuse of materials. By incorporating steel angles in construction projects, cities can create sustainable infrastructure that contributes to the overall well-being of the environment and the community.

- Q: Can steel angles be used for railings or barriers?

- Yes, steel angles can be used for railings or barriers. Steel angles provide structural support and stability, making them suitable for creating sturdy railings and barriers.

- Q: Are steel angles suitable for corrosive environments?

- Corrosive environments can be suitable for steel angles depending on the specific conditions and the type of steel utilized. Stainless steel angles, for instance, exhibit exceptional resistance against corrosion due to their composition rich in chromium and nickel. These angles find extensive application in environments that encounter moisture, chemicals, or saltwater, such as marine applications or industrial settings. On the other hand, carbon steel angles may not be as appropriate for corrosive environments as they tend to be more susceptible to rust and corrosion. In such instances, it may be necessary to employ additional protective measures like coatings or galvanization to enhance their resistance against corrosion. To determine the most suitable steel angles for corrosive environments, it is crucial to consider the specific corrosive elements present in the environment, the extent of exposure, and the desired longevity of the angles. Seeking guidance from a corrosion specialist or an engineer with expertise in materials selection can aid in making informed decisions.

- Q: What is the cost of steel angles compared to other materials?

- The cost of steel angles compared to other materials can vary depending on various factors such as the type and grade of steel, market conditions, and availability. However, in general, steel angles tend to be a cost-effective option when compared to other materials commonly used for structural or construction purposes. Steel angles are widely used in various industries including construction, manufacturing, and infrastructure due to their durability, strength, and versatility. Compared to materials like aluminum or stainless steel, steel angles are often more affordable. This is because steel is a widely available material and can be produced in large quantities, leading to cost efficiencies in manufacturing processes. Additionally, steel angles have a long lifespan and require minimal maintenance, further contributing to their cost-effectiveness over time. They also offer excellent load-bearing capabilities, making them suitable for a wide range of applications, including building frames, support structures, and machinery. However, it is important to note that the cost of steel angles can still vary depending on the specific requirements and specifications of a project. Factors such as size, length, thickness, and any additional treatments or finishes can influence the price. Therefore, it is advisable to consult with suppliers or manufacturers to obtain accurate and up-to-date pricing information based on individual project needs.

- Q: How do you calculate the torsional capacity of a steel angle?

- To calculate the torsional capacity of a steel angle, you need to consider the material properties and dimensions of the angle. The torsional capacity refers to the maximum amount of torque or twisting force that the angle can withstand without experiencing significant deformation or failure. The torsional capacity can be determined using the following steps: 1. Determine the cross-sectional properties: Measure the dimensions of the steel angle, including the thickness, width, and length. Calculate the area moment of inertia (I) and the polar moment of inertia (J) of the cross-section. These properties provide information about the resistance of the angle to torsional forces. 2. Determine the material properties: Obtain the material properties of the steel angle, such as the yield strength (σy) and the ultimate strength (σu). These values indicate the maximum stress that the material can withstand before permanent deformation or failure occurs. 3. Calculate the torsional stress: Using the applied torque (T), calculate the torsional stress (τ) on the angle. Torsional stress is the torque divided by the polar moment of inertia (τ = T / J). This calculation determines the amount of twisting force experienced by the angle. 4. Determine the safety factor: Divide the yield strength of the material by the calculated torsional stress (SF = σy / τ). The safety factor represents the ratio of the maximum stress that the angle can withstand (yield strength) to the actual stress it experiences. A higher safety factor indicates a greater margin of safety. 5. Compare the safety factor to a desired value: Depending on the specific application and design requirements, a minimum safety factor may be specified. If the calculated safety factor is below the desired value, it indicates that the angle is not suitable for the intended torsional load and a different angle or design modification may be necessary. It is important to note that these calculations provide an estimation of the torsional capacity, and other factors such as the presence of holes, welds, or other geometric irregularities can affect the actual torsional behavior of the angle. Therefore, it is recommended to consult relevant design codes or professional engineering resources for detailed calculations and recommendations specific to your application.

Send your message to us

Hot Rolled Steel Angle Bar with High Quality 30*30mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords