HOT ROLLED STEEL ANGLE BAR EAL QUAL ANGLE BAR Q235 JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Structure Steel Angle Bar

1.Invoicing on theoretical weight or actual weight as customer request

2.Standards:GB,ASTM,BS,AISI,DIN,JIS3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

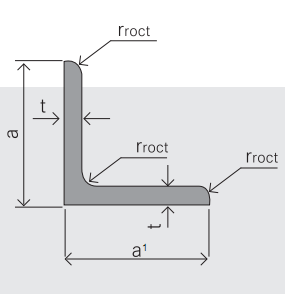

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Structure Steel Angle Bar

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

- Q: Are steel angles fire resistant?

- Steel angles are commonly regarded as fire resistant. This is because steel is a material that does not burn and can withstand high temperatures. Steel angles, which are L-shaped structural components, are widely used in construction and engineering due to their strength and durability. In the event of a fire, steel angles remain structurally intact and do not deform, which is crucial for the safety of a building or structure. However, it is important to consider that the fire resistance of steel angles may be influenced by various factors such as size, thickness, fire protection measures, and the duration and intensity of the fire. To enhance the fire resistance of steel angles and improve overall fire safety, measures like fire-resistant coatings, fire barriers, and fireproofing materials can be employed.

- Q: Can steel angles be used in marine environments?

- Yes, steel angles can be used in marine environments. However, it is crucial to select the appropriate grade of stainless steel or corrosion-resistant coating to prevent corrosion and ensure durability in the harsh marine conditions.

- Q: Can steel angles be used in seismic or high-wind areas?

- Yes, steel angles can be used in seismic or high-wind areas. Steel angles are commonly used in construction for their strength and durability. They provide structural support and can withstand seismic forces and high winds when properly designed and installed. The use of steel angles in these areas is often subject to specific building codes and regulations, which ensure that the structures are capable of withstanding the forces generated by earthquakes or strong winds. Engineering analysis and design considerations must be taken into account to ensure the appropriate size, configuration, and connection details of the steel angles in order to meet the required safety standards.

- Q: How do you protect steel angles from weathering?

- There are various effective methods available for protecting steel angles from weathering. The primary approach involves the application of a specially designed coating or paint that is intended for steel surfaces. This coating acts as a barrier, preventing direct contact between moisture, oxygen, and the steel, thereby reducing the likelihood of rust formation. It is crucial to select a weather-resistant coating that offers long-term durability. Before applying the protective coating, it is essential to thoroughly clean the steel angles to eliminate any dirt, grease, or existing rust. This can be accomplished through abrasive cleaning techniques such as sandblasting or by using a wire brush. Once the cleaning process is complete, the surface should be primed with a corrosion-resistant primer, which improves the adhesion of the protective coating. Regular maintenance is also vital to ensure the continuous protection of steel angles from weathering. This involves periodically inspecting the coating for any signs of damage or wear and promptly addressing any issues that arise. Touching up areas where the coating has been compromised is necessary to maintain the integrity of the protective layer. In addition, proper design and installation techniques can contribute to protecting steel angles from weathering. It is crucial to ensure that the angles are adequately sealed and shielded from direct exposure to rain, snow, or other sources of moisture. This can be achieved by implementing appropriate drainage systems, such as gutters or downspouts, to redirect water away from the steel angles. Lastly, considering alternative materials or coatings that possess inherent resistance to weathering, such as stainless steel or galvanized steel, can provide an additional layer of protection against environmental elements. These materials have higher corrosion resistance and are more suitable for outdoor applications where weathering is a concern. By implementing a combination of protective coatings, regular maintenance, proper design, and the utilization of weather-resistant materials, steel angles can be effectively safeguarded from weathering while maintaining their structural integrity over an extended period.

- Q: Can steel angles be used in the construction of power plants?

- Yes, steel angles can be used in the construction of power plants. Steel angles are commonly used in structural applications and are well-suited for supporting heavy loads and providing structural stability. In power plant construction, steel angles can be utilized for various purposes such as framing structural components, supporting equipment and machinery, reinforcing concrete structures, and providing structural integrity to the overall plant infrastructure. Additionally, steel angles offer excellent resistance to corrosion, which is particularly important in power plants where exposure to high temperatures, moisture, and chemicals is common. Overall, the versatility, strength, and durability of steel angles make them a suitable choice for use in the construction of power plants.

- Q: Can steel angles be used for manufacturing storage racks?

- Indeed, storage racks can be manufactured using steel angles. With their versatility and strength, steel angles prove to be an optimal option for the construction of such racks. By providing stability and structural integrity, they guarantee the capability to bear substantial loads. Moreover, steel angles allow for the seamless welding or bolting together, enabling the production of tailor-made racks that satisfy specific storage needs. The longevity of steel angles further assures the endurance of the storage racks against gradual deterioration. As a result, steel angles find widespread application in the manufacturing of storage racks across diverse industries encompassing warehousing, retail, and logistics.

- Q: What are the different types of steel angles connections for joists?

- There are several different types of steel angle connections for joists, including welded connections, bolted connections, and clip connections. Welded connections involve welding the steel angle to the joist, providing a strong and permanent connection. Bolted connections involve using bolts to secure the steel angle to the joist, allowing for easy disassembly if needed. Clip connections involve using clips to attach the steel angle to the joist, providing a quick and efficient connection. Each type of connection has its advantages and is chosen based on factors such as load requirements, construction method, and budget.

- Q: What is the process of punching holes in steel angles?

- The process of punching holes in steel angles involves several steps. First, the steel angle is measured and marked according to the desired hole placement. This is typically done using a measuring tape and a marker or scribe. Once the markings are made, the steel angle is clamped securely onto a work table or a specialized punching machine. This ensures that the angle remains stable during the hole punching process. Next, a punch and die set specifically designed for steel angles is selected. The punch is the tool that creates the hole, while the die supports the material and helps to produce clean and accurate holes. The punch and die set is aligned with the marked location on the steel angle. This is done by positioning the punch directly above the desired hole and ensuring that it is centered and level. The die is placed underneath the angle to provide support. Using a hydraulic or mechanical press, pressure is applied to the punch. This causes it to penetrate through the steel angle, creating a hole. The force applied depends on the thickness and hardness of the steel angle, as well as the size of the hole being punched. After the hole is punched, the punch and die set is removed from the steel angle. The angle is then inspected to ensure that the hole is clean and free from any burrs or deformations. If necessary, any imperfections can be smoothed out using a deburring tool or sandpaper. Overall, the process of punching holes in steel angles requires careful measurement, marking, clamping, alignment, and the use of specialized tools. It is important to follow proper safety procedures and use appropriate protective equipment, such as gloves and goggles, to prevent injury during the process.

- Q: Can steel angles be used for manufacturing vehicle frames?

- Yes, steel angles can be used for manufacturing vehicle frames. Steel angles provide structural support and are commonly used in the construction of vehicle frames due to their strength, durability, and ability to withstand heavy loads.

- Q: What is the weight of a steel angle?

- Determining the weight of a steel angle relies on its dimensions and density. In order to calculate the weight, it is necessary to possess knowledge of the length, width, and thickness of the steel angle. By multiplying the angle's volume (length x width x thickness) by the density of steel, the weight can be ascertained. Steel typically has a density of approximately 7.85 grams per cubic centimeter. Consequently, the weight of a steel angle can be computed using the formula: weight = volume x density.

Send your message to us

HOT ROLLED STEEL ANGLE BAR EAL QUAL ANGLE BAR Q235 JIS

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords