Hot Rolled Stainless Steel Coil (304/NO. 1)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Stainless Steel Coil description:

Model NO.:304

Type:Stainless Steel Strips

Shape:Coil

Grade:300 Series

Certification:SGS

Standard:AISI

Technique:Hot Rolled

Surface Treatment:Hot Rolled

Export Markets:Global

Packing:Standard Export Packing

Standard:ASTM, GB, SUS

Origin:China

Production Capacity:10000 Mt/Month

Product specification:

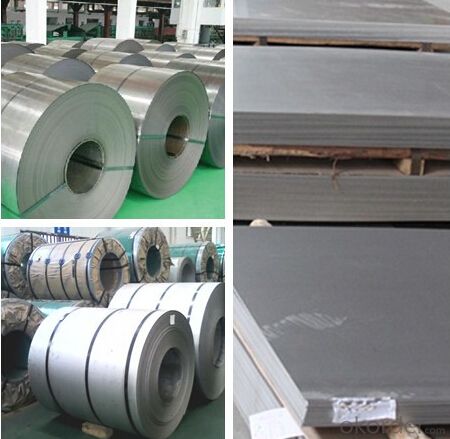

Commodity: Hot rolled stainless steel coil

Grade: 304

Finish: No. 1

Thickness: 3.0mm to 20.0mm

Width: 1219mm, 1500mm

Mill: TISCO, LISCO, BAOXIN, JISCO, SOUTHWEST

Quantity: 3000-5000MT every month

Thickness tolerance: +/-6%

Packing: Export standard packing

Coil weight: 10-20MT

Delivery time: Immediate shipment

Applications: Stainless Steel Cold Rolled Coils are widely applied to construction field, ships building industry, petroleum and chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

FAQ:

Acceptable payment term and way?

T/T,L/C, T/T + L/C, D/P

Acceptable price term

FOB CNF CIF DDU CPT

Do you accept OA payment terms?

Yes, sure, but it normally depending on the order value

Do you have QC team?

Yeah, sure, our QC team is very important, they will keep the qualitycontrol for our products.

What is the validity of your quotation?

Normally 7 days.

What is your advantage?

24 hour quick response /Customer oriented/ Credit foremost/ Top quality Excellent

What is your acceptable payment term?

TT,LC,OA etc

- Q: What are some characteristics of steel.

- Characteristics Of Steel Hardening. - The characteristic difference between steel and pure wrought iron is as follows: - When steel is raised to a red heat and then suddenly cooled, it becomes hard and brittle. This process, which is known as hardening, has no effect upon pure wrought iron. Tempering is a characteristic of steel which distinguishes it from cast iron. If steel has been hardened by being heated and suddenly cooled, as above described, it may be softened again by applying a lower degree of heat and again cooling. This is known as tempering. Cast iron, on the contrary, though it is hardened by the first process, cannot be softened by the second. When a bar of steel is struck it gives out a sharp metallic ring, quite different from the sound produced by striking wrought iron. Other characteristics of steel are its great elasticity and its retention of magnetism.

- Q: How are steel coils inspected for formability using forming tests?

- To assess their ability to be shaped into desired forms without any defects or failures, steel coils undergo inspections for formability through the use of forming tests. These tests are conducted to evaluate the mechanical properties of the material and determine if it is suitable for specific applications. Forming tests consist of subjecting the steel coil to different forming operations, such as bending, deep drawing, or stretch forming. The coil is typically cut into specific dimensions and then subjected to these operations using specialized equipment. The main objective is to replicate the actual forming process that the steel will experience in real-world applications. During the forming tests, several parameters are carefully monitored. These parameters include the amount of force or load applied, the rate of deformation, and the resulting strain or deformation experienced by the steel. Additionally, the response of the coil to these operations is observed, including any visible defects like cracks, fractures, or surface imperfections. By thoroughly analyzing the performance of the steel coil during the forming tests, various characteristics related to formability can be determined. These characteristics include the material's ability to resist deformation, its capacity to withstand strain without failure, and its tendency to exhibit defects under specific forming conditions. The results obtained from these tests provide valuable insights into the suitability of the steel coil for particular forming processes and applications. Furthermore, advanced techniques such as digital image correlation and strain analysis can be utilized to precisely measure and evaluate the distribution of strain across the surface of the steel coil. These techniques assist in identifying areas of the coil that experience higher strain and potential points of failure. In summary, the formability of steel coils is assessed through forming tests that simulate the actual forming processes they will undergo. These tests evaluate various formability characteristics, including the material's resistance to deformation and its likelihood of defects. The results obtained from these tests aid in determining the suitability of the steel coil for specific applications and guide the selection of appropriate forming parameters.

- Q: How are steel coils used in the production of steel hooks?

- Steel coils are used in the production of steel hooks as they serve as the primary raw material. These coils are unrolled and then undergo a series of processes such as cutting, shaping, bending, and welding to form the desired shape of the hook. The strength and durability of steel coils make them an ideal material for manufacturing steel hooks, ensuring they can withstand heavy loads and provide reliable support in various applications.

- Q: How are steel coils cut and shaped for specific requirements?

- Steel coils are cut and shaped for specific requirements through a process called slitting and forming. Slitting involves cutting the coil into narrower strips using specialized machinery, while forming utilizes presses, rollers, or other tools to shape the steel into desired profiles. These processes allow manufacturers to tailor the dimensions and shape of the steel coils to meet specific industry and customer requirements.

- Q: What is the process of pickling and oiling steel coils?

- The process of pickling and oiling steel coils involves several steps. First, the steel coils are immersed in a pickling bath containing a mixture of acids to remove any impurities, scale, and rust from the surface of the steel. This helps to improve the quality and appearance of the steel. After pickling, the coils are rinsed with water to remove any residual acid. Next, the coils are coated with a thin layer of oil. This oil acts as a protective barrier, preventing the steel from rusting or corroding during storage, transportation, and further processing. The oil also helps to enhance the surface finish of the steel. The pickled and oiled steel coils are then typically rolled or processed further according to specific requirements. This could involve additional annealing, cold rolling, or other treatments to achieve the desired properties or dimensions. Overall, the pickling and oiling process is crucial in preparing steel coils for various applications, ensuring they are clean, corrosion-resistant, and ready for further processing or use.

- Q: Can steel coils be stored in a corrosive environment?

- No, steel coils should not be stored in a corrosive environment as it can lead to the degradation of the steel surface and compromise its structural integrity.

- Q: I was wondering what material most common motorcycle gas tanks are made out of? is it steel? stainless steel? aluminum? what are the advantages and disadvantages or each?

- Steel is the norm. Aluminum is lighter, but can be prone to cracking from vibration. It is seen more often in custom tanks, especially for custom cafe racers, Guzzis, Ducatis, Tritons, and the like. Dirt bikes use plastic tanks. Most after-market tanks for dual sports and adventure tourers are also made from plastic.

- Q: I just got the game Red Steel for the Wii. I want to use the sword in multiplayer mode, but I can't find it. Is it only for single player?

- Dude i hate to break it to you but its only single player, and if your talking about the first Red Steel, you can only use the sword in special moments in the game or showdowns i think that's what its called, but i play Red Steel 2, and its a better game, and you can use the sword anytime you want to, but again no online play, but it would be kinda nice to have it, just a thought!!! LoL Hope that helps....

- Q: How are steel coils used in the manufacturing of safety systems?

- Steel coils are commonly used in the manufacturing of safety systems such as airbags and seat belts. The steel coils are formed into springs which provide the necessary tension and force to ensure the proper functioning of these safety devices. The coils are carefully designed and integrated into the system to enhance its performance and reliability, ultimately helping to protect occupants in the event of a collision.

- Q: How are steel coils used in the manufacturing of electrical equipment?

- Steel coils are used in the manufacturing of electrical equipment as they provide structural support and help in the efficient transfer of electrical energy. They are commonly used in transformers, motors, and generators to create magnetic fields that enable the conversion and transmission of electrical power.

Send your message to us

Hot Rolled Stainless Steel Coil (304/NO. 1)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords