Hot Rolled Stainless Steel Coil 304 Wide Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

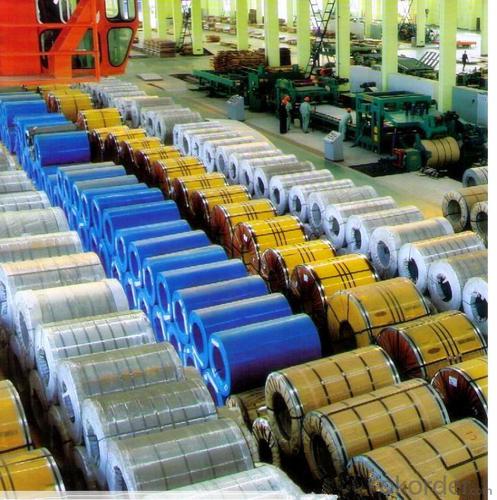

Hot Rolled Stainless Steel Coil 304 Wide Strip

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely

used in light industry,heavy industry,daily necessities and the decoration industry.my company long-term

supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube.

Specifications

1.surface:NO.1

2.standard:JIS, AISI, GB

3.width: 1.0m, 1.22m, 1.5m, 2.0m or requirement

ASTM 304

(%):C=0.07, Mn=2.00, P=0.045, S=0.030, Si=0.075, Cr=17.5-19.5, Ni=8.0-10.5, N=0.10

Physical Properties

Tensile strength σb (MPa) ≥ 520

the conditions yield strength σ0.2 (MPa) ≥ 205,

elongation δ5 (%) ≥ 40

Reduction of ψ (%) ≥ 50,

hardness: ≤ 187

HB; ≤ 90

HRB; ≤ 200H

Type | Hot Rolled Stainless Steel Coil 304 |

Thickness | 3.0mm-4.0mm |

Width | 1000mm, 1219mm, 1240mm, 1500mm |

Length | according to weight |

Brand name | CNBM |

Standard | ASTM, AISI, DIN, GB, JIS etc |

Material | 304 |

Application | Foodstuff, Gas, metallurgy, biology, electron, chemical, petroleum, boiler, nuclear energy, Medical equipment, fertilizer etc |

Package | Standard export sea-worthy packing |

Delivery time | Within 15 days since getting the deposit or LC origin |

Surface | NO.1 |

Productivity | 5000 tons/month |

- Q: What is the creep strength of stainless steel strips?

- The ability of stainless steel strips to withstand long-term deformation under elevated temperatures and constant load is referred to as the creep strength. Stainless steel is well-known for its exceptional resistance to creep due to its high alloy content and specific microstructure. Various factors, including alloy composition, heat treatment, and grain size, influence the creep strength of stainless steel strips. Compared to other materials, stainless steel strips generally display high creep strength, particularly at elevated temperatures. The inclusion of elements like chromium, nickel, and molybdenum enhances the creep resistance of stainless steel, enabling it to maintain its shape and structural integrity over extended periods of constant load. Moreover, the heat treatment process plays a crucial role in optimizing the creep strength of stainless steel strips. Employing appropriate techniques such as annealing or solution treatment followed by aging can enhance the material's microstructure and minimize the formation of detrimental phases like sigma phase, which can diminish creep resistance. The grain size of stainless steel also impacts its creep strength. Fine-grained stainless steel strips tend to exhibit superior creep resistance compared to those with coarse grains. This is because fine grains impede the movement of dislocations, which are responsible for creep deformation. Overall, stainless steel strips possess relatively high creep strength, making them well-suited for applications that require resistance to long-term deformation and high temperatures, such as in the power generation, aerospace, and chemical processing industries.

- Q: What is the thermal expansion coefficient of stainless steel strips?

- The thermal expansion coefficient of stainless steel strips can vary depending on the specific grade of stainless steel being used. However, in general, stainless steel has a relatively low coefficient of thermal expansion compared to other materials. The coefficient of thermal expansion is a measure of how much a material expands or contracts when exposed to changes in temperature. Stainless steel typically has a coefficient of thermal expansion ranging from about 10 to 17 µm/m°C (micrometers per meter per degree Celsius). This means that for every degree Celsius increase in temperature, a stainless steel strip will expand by approximately 10 to 17 micrometers per meter in length. It is important to note that the exact coefficient of thermal expansion may vary depending on the specific alloy composition and heat treatment of the stainless steel. Therefore, it is recommended to consult the manufacturer's specifications or conduct specific testing to determine the precise thermal expansion coefficient of a particular stainless steel strip.

- Q: How do stainless steel strips perform in the presence of ammonia?

- Ammonia is generally well tolerated by stainless steel strips, which are widely recognized for their outstanding resistance to corrosion. This resistance is particularly evident when it comes to ammonia and its compounds, thanks to the high chromium content present in stainless steel. This chromium forms a protective layer on the surface, effectively shielding the metal from any reactions with ammonia. Moreover, stainless steel's non-porous nature further enhances its ability to repel ammonia and reduce the likelihood of corrosion. Nevertheless, it is worth noting that the performance of stainless steel strips in the presence of ammonia can be influenced by various factors, including the concentration and temperature of the ammonia solution, as well as the specific grade and surface finish of the stainless steel. Consequently, it is advisable to seek guidance from stainless steel manufacturers or corrosion experts when using stainless steel strips with ammonia. This way, the most suitable material selection and maintenance practices can be ensured for specific applications involving stainless steel strips and ammonia.

- Q: How do stainless steel strips resist erosion?

- Stainless steel strips have the ability to resist erosion due to their unique composition and properties. Firstly, stainless steel is an alloy that contains a high percentage of chromium, which forms a protective layer of chromium oxide on the surface of the steel. This layer acts as a barrier, preventing oxygen and moisture from reaching the underlying metal and thus protecting it from corrosion and erosion. Additionally, stainless steel strips are also highly resistant to acids, alkalis, and various chemicals, which makes them suitable for applications in harsh environments. The presence of other alloying elements such as nickel and molybdenum further enhances the corrosion resistance of stainless steel. Furthermore, the structure of stainless steel, particularly the austenitic stainless steel, provides excellent strength and toughness, making it more resistant to mechanical erosion. The combination of its corrosion resistance and mechanical properties makes stainless steel strips highly durable and able to withstand erosive forces. Moreover, stainless steel strips can be treated with various surface finishes like passivation or electro-polishing, which further improves their resistance to erosion. These treatments remove impurities and contaminants from the surface, creating a smoother and more corrosion-resistant finish. Overall, the ability of stainless steel strips to resist erosion can be attributed to their corrosion-resistant composition, surface treatments, and excellent mechanical properties. These factors make stainless steel an ideal material for various applications where erosion resistance is crucial, such as in the manufacturing of automotive components, kitchen appliances, and chemical processing equipment.

- Q: Can stainless steel strips be used for automotive exhaust systems?

- Certainly, automotive exhaust systems can utilize stainless steel strips. Stainless steel's exceptional resistance to corrosion, high temperatures, and remarkable strength render it a widely favored option for exhaust systems. The flexibility of stainless steel strips enables convenient fabrication and formation into desired shapes for exhaust components including pipes, mufflers, and catalytic converters. Furthermore, the enduring nature of stainless steel, capable of withstanding extreme temperatures, exposure to diverse chemicals, and environmental elements, ensures its status as a durable and long-lasting material for automotive exhaust systems.

- Q: What are the common surface finishes for stainless steel strips?

- Stainless steel strips can be finished in different ways to achieve various appearances and functions. Here are some commonly used surface finishes: 1. Basic Finish: After being hot or cold rolled, stainless steel strips have a dull and non-reflective appearance, known as the mill finish. 2. Textured Finish: By brushing the stainless steel strip with abrasive materials, a textured appearance is achieved. This brushed finish helps to conceal surface imperfections and gives the strip a satin-like finish. 3. Reflective Finish: The stainless steel strip is mechanically polished, resulting in a smooth and reflective surface. This polished finish is often used for decorative purposes and is available in different levels of polish, such as mirror polish or satin polish. 4. Embossed Finish: To add texture and visual interest, the stainless steel strip is passed through embossing rollers, creating raised or sunken patterns on the surface. 5. Patterned Finish: Various techniques, like etching or laser engraving, can be used to create decorative patterns or designs on the surface of stainless steel strips. This gives the strip a unique and distinctive look. 6. Coated Finish: To enhance appearance or provide extra protection against corrosion, a thin layer of another material, such as a polymer or a metal, can be applied to the stainless steel strip. These finishes cater to different applications, offering a range of aesthetics and functionality.

- Q: Are stainless steel strips suitable for heat treatment processes?

- Yes, stainless steel strips are suitable for heat treatment processes. Heat treatment can help improve the mechanical properties, such as hardness and strength, of stainless steel strips. Different heat treatment processes, such as annealing, tempering, and quenching, can be used to achieve specific material properties and desired outcomes in stainless steel strips.

- Q: Can stainless steel strips be used in food processing industries?

- Yes, stainless steel strips can be used in food processing industries. Stainless steel is highly resistant to corrosion, easy to clean, and has excellent hygiene properties, making it a preferred choice for equipment, machinery, and surfaces in food processing facilities.

- Q: How do you determine the corrosion resistance of a stainless steel strip?

- To determine the corrosion resistance of a stainless steel strip, various tests can be conducted. One commonly used method is the salt spray test, where the strip is exposed to a saltwater mist for a specified period. The strip's performance is evaluated by observing any signs of corrosion, such as rust or discoloration. Additionally, electrochemical tests, such as the polarization test or the potentiodynamic scan, can be conducted to measure the strip's corrosion potential and resistance. These tests provide valuable insights into the strip's ability to withstand corrosion in different environments.

- Q: Are 111 stainless steel strips suitable for harsh chemical environments?

- The suitability of 111 stainless steel strips for harsh chemical environments is questionable. These strips belong to a low alloy grade that lacks the same corrosion resistance found in stainless steel grades like 304 or 316. When exposed to harsh chemicals, particularly acids and chlorides, 111 stainless steel is more prone to corrosion and damage. Hence, it is advisable to opt for stainless steel strips with higher alloy content and superior corrosion resistance in order to guarantee durability and longevity in such challenging chemical environments.

Send your message to us

Hot Rolled Stainless Steel Coil 304 Wide Strip

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords