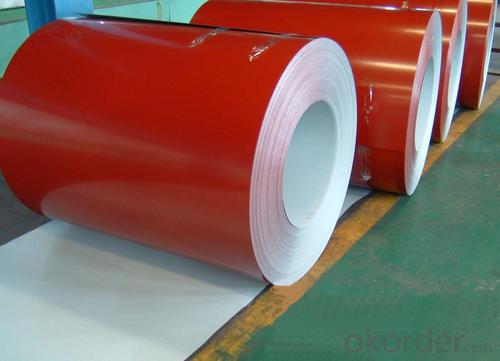

color Coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications:

1. Thickness: 0.12mm-1.3mm

2. Width: 600mm-1250mm

3. Length: According to client's demands

4. Top paint: 15 to 25 um (5 um + 12-20 um)

Back paint: 7 +/- 2 um

5. Gloss: Normal or High gloss

6. Zinc coating: Z50-Z275G/psm

7. Inside Diameter: 508mm/610mm

8. Outside Diameter: 1000mm-1500mm

9. Coil weight: 3-8 tons

10. Payment: T/T, L/C, D/P, Paypal, Western Union

11. Trade Term: FOB, CFR, CIF

12. MOQ: 25 Mt

13. Package: Export standard package or as request

14. Shipment: By container

15. Standard: AISI, ASTM, BS, DIN, GB, JIS

16. Grade: JIS G3322, CGLCC, ASTM A755, CS-B

| Resin constructure Technique of production | Double painting and double baking process |

| Productivity | 150,000Tons/year |

| Thickness | 0.12-1.3mm |

| Width | 600-1250mm |

| Coil Weight | 2-7 Tons |

| Inside Diameter | 508mm Or 610mm |

| Outside Diameter | 1000-1500mm |

| Zinc Coating | Z50-Z275G |

| Painting | Top: 15 to 25 um (5 um + 12-20 um) back: 7 +/- 2 um |

| Standard | JIS G3322 CGLCC ASTM A755 CS-B |

| SurfSurface coating coloace coating type | PE, SMP, HDP, PVDF |

| Back side coatingcolor | Light grey, white and so on |

| Application | PPGI is featured with light-weight, good looking and anticorrosion. It can be processed directly, mainly used for construction industry, home electronic apparatus industry, electronic apparatus industry, furniture industry and transportation. |

- Q: What is the cost of a steel coil?

- The cost of a steel coil can vary depending on various factors such as the size, thickness, grade, and market conditions. It is best to contact a supplier or check current market prices for an accurate cost.

- Q: where to buy Transformer steel?Used in transformers and electric motors.

- Here okorder

- Q: i wanna buy a sharp carbon steel sword the swords i want are a 200 layer carbon steel katana or a hand forged high carbon steel katanna or a hand sharpened sword which one would be sharper/stronger

- Carbon steel is a generic term. There are many different grades of carbon steel consisting of several different components of various amounts, and there are different types of treatment the steel can go through that changes it's quality. Carbon steel swords are a step up from the crappy stainless steel swords, and other alloys. Sword quality completely depends on the smith. 200 layers doesn't mean there won't be any imperfections. Sword makers make mistakes, especially the lesser experienced ones. Look into the maker(s) of the sword you're looking to buy. Find information on them before deciding. Carbon steel is the steel to have, but that doesn't exclude good or bad quality. Sharpness will depend on the the steel and the smith.

- Q: How are steel coils used in the manufacturing of packaging materials?

- Steel coils are used in the manufacturing of packaging materials by being transformed into various forms, such as sheets or strips, that can be used for packaging products. These coils are often processed through cutting, shaping, and coating techniques to create packaging materials like cans, drums, or containers. The durability and strength of steel make it an excellent choice for packaging materials, ensuring the safe transportation and preservation of goods.

- Q: mass of steel ball=66.80 gramsdiameter of steel ball=2.51 cm

- Density Of A Ball

- Q: I wrote in my assignment that mild steel has a high carbon content (4%).This is why it has its strong and rigid properties.. is this correct?

- High carbon steel is much harder than iron. In fact, steel -is- iron with carbon in it. Mild steel has a very low carbon content and is much softer. High carbon steel is much stronger after heat treatment. However, about 2% carbon, it is considered cast iron. Mild steel contains about 0.16% to 0.29% carbon content. It has a relatively low strength but is highly malleable.

- Q: What are the common applications of hot-rolled steel coils?

- Hot-rolled steel coils are commonly used in various applications such as construction, automotive manufacturing, pipe and tube manufacturing, shipbuilding, and general engineering purposes. They are particularly suitable for projects that require strong and durable materials, as well as those that involve shaping and forming processes.

- Q: I downloaded broken steel, the notice of my level cap raising was shown, but after reaching the Jefferson Memorial (when you are supposed to activate the purifier) if I kill Colonel Autumn, then Lyons simply says that we must secure the area, and I can't complete the mission. If I let Autumn live, then she gets stuck in a loop saying Steel be with you over and over. Has anyone else experienced this/how can I fix this? I paid $10 for the expansion and I'm getting ripped off.

- Broken Steel alters the ending of the original Fallout 3 to allow continued play after the end of the main quest line. This means that when it is time to go into the reactor at the end of Take it Back!, you can still go in yourself or you can send one of three side characters. However, even if you go yourself, you do not die. Instead, you survive the ordeal and wake up two weeks later at the Citadel. If you allow the Purifier to explode, the game will still end. Elder Lyons will inform you that you and Sarah Lyons were knocked unconscious by an unknown energy spike. Sarah will still be in a coma

- Q: is there a type of steel that is stronger or does the rail represent the top of the line?

- consumer-friendly steel is used however the rails are tempered to cause them to stand up to the pounding they get from the practice wheels,the intense velocity trains utilized in Europe are made up of a greater variety of steel in accordance to organization who makes them in Germany ,i think of it replaced into Krupp's of Germany who cause them to

- Q: Can i make holes in iron and steel with somekind of drill bit. All i have is metal drill bits. Mabey like 68 of them but i dont know wich one to use and if they will penetrate.

- It really depends. If you are drilling iron, I assume you are talking about cast irons and there are many different types, some are easier to drill (and machine) than others. For steels, there are many many different types of steels which can have a huge range of physical properties. In fact, your drill bits are almost certainly made of some type of steel alloy. If your drill bit has the same hardness as the steel you are trying to drill, it will be difficult to drill. If the steel is harder than the drill bit, you won't make a hole, you'll just break your drill bit into smaller pieces. There are drill bits that use carbide inserts or diamond composite inserts and these will drill through steel. You can do a quick check. Take a drill bit and, just by hand, see if it scratches the steel. If it does, then the drill bit is harder than the steel and you can probably drill a hole. If you have trouble drilling holes, consult a machinist. There are many factors which influence how well you can drill holes including use of cutting oils/lubricants, cutting speed, pressure, rake angle, etc.

Send your message to us

color Coated Galvanized cold Rolled Steel coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords