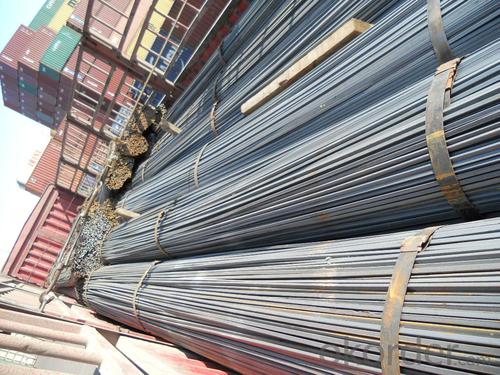

Hot Rolled Structure Steel Square Bar with Many sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Structure Steel Square Bar at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

The Square Steel is normally used as structure steel.

Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

Product Advantages:

OKorder's Hot Rolled Structure Steel Square Bar are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | 33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | 35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | 55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | 58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

23 | 4.15 | 65 | 33.17 |

24 | 4.52 | 68 | 36.3 |

25 | 4.91 | 70 | 38.49 |

26 | 5.30 | 75 | 44.16 |

27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, The numbers with mean that they are not regulars or we don’t offer them.

-List 2. The allowed tolerance of Square Steel:

Length of a side(mm) | Allowed Tolerance | ||

Group1 | Group2 | Group3 | |

5.5~7 | ±0.20 | ±0.30 | ±0.40 |

7~20 | ±0.25 | ±0.35 | ±0.40 |

20~30 | ±0.30 | ±0.40 | ±0.50 |

30~50 | ±0.40 | ±0.50 | ±0.60 |

60~80 | ±0.60 | ±0.70 | ±0.80 |

80~110 | ±0.90 | ±1.0 | ±1.1 |

110~150 | ±1.2 | ±1.3 | ±1.1 |

150~190 | ―― | ―― | ±2.0 |

190~250 | ―― | ―― | ±2.5 |

Payment:

-Invoicing on theoretical weight or actual weight as customer’s request.

-Regular terms of payment:

1, 30% payment in advance, the remaining balance (70% payment) against the copy of B/L.

2, 30% payment in advance, the remaining balance (70% L/C) against the copy of B/L.

3, Negotiable.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

A4: Stainless steel must contain at least 10.5 % chromium. It is this element that reacts with the oxygen in the air to form a complex chrome-oxide surface layer that is invisible but strong enough to prevent further oxygen from "staining" (rusting) the surface. Higher levels of chromium and the addition of other alloying elements such as nickel and molybdenum enhance this surface layer and improve the corrosion resistance of the stainless material.

- Q: Can a steel square be used for checking the plumbness of a column?

- Checking the plumbness of a column cannot be done using a steel square. A steel square, known as a framing square or carpenter's square, is primarily used for measuring and marking right angles in carpentry and construction work. It consists of a long, straight edge with a perpendicular arm, forming an L-shape. Although it can be helpful for tasks like checking angles or laying out cuts, it lacks the necessary features and precision to determine the plumbness of a column. To appropriately check the plumbness of a column, a plumb bob or a level would be more suitable tools. A plumb bob is a weighted object attached to a string that, when suspended, aligns itself vertically due to gravity. By placing the plumb bob against the column, one can ascertain if it is perfectly vertical or not. On the other hand, a level has a bubble that moves within a vial, indicating whether a surface is level or plumb. By placing the level against the column, one can easily check if it is perfectly plumb or if adjustments are needed. In conclusion, although a steel square is versatile in construction, it is not appropriate for checking the plumbness of a column. To ensure accurate results, a plumb bob or level should be used for this specific task.

- Q: Can a steel square be used for checking the squareness of cabinet frames?

- Yes, a steel square can be used for checking the squareness of cabinet frames. Steel squares are commonly used in carpentry and woodworking for measuring and verifying right angles. They are accurate and reliable tools for determining if cabinet frames are square and ensuring their proper alignment.

- Q: Can a steel square be used for checking the squareness of furniture assemblies?

- Furniture assemblies can be checked for squareness using a steel square. This versatile tool, also known as a framing square or carpenter's square, is commonly used in carpentry and woodworking to guarantee accurate right angles and squareness. It features a right-angle shape, comprising one long arm and one shorter arm joined at a 90-degree angle. To evaluate the squareness of furniture assemblies, simply position the steel square against the corners or edges of the furniture piece. By aligning the long arm of the square with one side of the furniture and the shorter arm with the adjacent side, you can visually examine whether the two sides meet at a perfect right angle. If the furniture is square, the steel square's edges should align flawlessly with the furniture's edges, signifying proper assembly. Using a steel square offers a convenient and swift method to ensure the squareness of furniture assemblies, particularly for smaller or less intricate pieces. However, for larger or more complex furniture items, additional measuring and leveling tools may be necessary to guarantee precise squareness.

- Q: What are some common applications for a steel square in roofing installations?

- Some common applications for a steel square in roofing installations include measuring and marking angles, cutting rafters and other framing materials, checking for squareness and straightness, and laying out roof lines and slopes.

- Q: How do you use a steel square to determine the angle of a compound spindle sanding cut?

- To determine the angle of a compound spindle sanding cut using a steel square, follow the following steps: 1. Place the steel square on a flat and level surface, like a workbench or table. 2. Securely position the compound spindle sanding machine next to the steel square, ensuring its stability. 3. Set the desired angle for the cut by adjusting the angle of the compound spindle sanding machine. This can usually be done by loosening a locking mechanism or turning a knob. 4. Once the desired angle is set, press the steel square against the sanding spindle or workpiece, ensuring it is flush against both surfaces. 5. Observe the angle formed between the square and the sanding spindle or workpiece. This angle represents the compound spindle sanding cut angle. 6. Take note of the angle measurement indicated by the steel square. Some steel squares may have angle markings or a protractor scale to aid in accurate measurements. 7. Use the determined angle measurement as a guide for your compound spindle sanding cut. Adjust the angle of the machine or workpiece accordingly to achieve the desired outcome. Remember to prioritize safety at all times when working with power tools and machinery. Ensure the compound spindle sanding machine is securely fastened and wear appropriate safety gear, such as goggles and gloves.

- Q: Can a steel square be used for checking the squareness of a circular saw blade?

- No, a steel square cannot be used for checking the squareness of a circular saw blade. A steel square is designed specifically to measure right angles, not the squareness of a circular object. The circular saw blade is a round object, and its squareness refers to the alignment of the blade's teeth with the cutting plane. To properly check the squareness of a circular saw blade, specialized tools such as a dial indicator or a dedicated blade alignment gauge should be used. These tools are specifically designed to accurately measure the squareness of a circular saw blade and ensure precise and accurate cuts.

- Q: How do you use a steel square to measure the width of a worktable?

- To use a steel square to measure the width of a worktable, you can follow these steps: 1. Ensure the worktable is clean and free from any objects that may obstruct the measurement process. 2. Place the steel square on one end of the worktable, positioning it flush against the edge. Make sure the long side of the square is aligned with the width you are trying to measure. 3. Hold the steel square firmly in place, ensuring that it doesn't move or shift during the measurement. 4. Look at the measurement markings on the steel square and identify the corresponding width measurement. 5. Read the measurement on the steel square where it aligns with the other end of the worktable. This should give you the accurate width of the worktable. 6. Take note of the measurement and repeat the process if necessary to double-check the accuracy. It's important to handle the steel square carefully and ensure it is properly aligned with the edges of the worktable to get an accurate measurement.

- Q: How do you use a steel square to mark out 60-degree angles?

- To use a steel square to mark out 60-degree angles, you can follow these steps: 1. Start by placing the steel square on the surface or material you want to mark the angle on. Ensure that one edge of the square aligns with the starting point of the angle. 2. Locate the 60-degree angle on the steel square. Most steel squares have markings or notches indicating different angles. Look for the one that represents 60 degrees. 3. Align the marking for 60 degrees on the steel square with the edge of the material or surface. Make sure the square is securely held in place to avoid any movement. 4. Once the steel square is properly aligned, use a pencil or a marking tool to trace along the edge of the square, marking the 60-degree angle on the material. 5. Repeat the process if necessary, ensuring that the square is aligned correctly each time to maintain accuracy. Using a steel square to mark out 60-degree angles is an efficient way to achieve precise measurements. Remember to always double-check your alignment and use a sharp marking tool for accurate results.

- Q: How do you use a steel square for marking stair baluster spacing?

- Achieving precise stair baluster spacing can be easily accomplished by following a few straightforward steps when utilizing a steel square. 1. Begin by measuring the width of the baluster you intend to use. This measurement will determine the spacing between each individual baluster. 2. Transfer the width measurement to the steel square, ensuring that you align it with the corresponding edge that matches the baluster width. 3. Place the square on either the handrail or the bottom rail of the stair railing, depending on where you wish to mark the baluster spacing. Make certain that the square's edge is parallel to the rail and align it with the starting point. 4. Employ a pencil or marker to mark the rail at the opposite edge of the steel square. This marking will serve as an indication of the initial baluster placement. 5. Slide the square along the rail, aligning its edge with the prior mark, and repeat the marking process until you have marked the desired number of baluster placements. 6. Verify your markings to confirm that they are evenly spaced and properly aligned. 7. After completing all the necessary marks, proceed with installing the balusters in accordance with the designated locations. By utilizing a steel square for marking stair baluster spacing, you can rely on a dependable and consistent approach to ensure accurate baluster placement. This method assists in maintaining a uniform appearance throughout the railing, resulting in an aesthetically pleasing finished product.

- Q: Can a steel square be used for cabinet making?

- Yes, a steel square can be used for cabinet making. A steel square, also known as a framing square or carpenter's square, is a versatile tool that is commonly used in woodworking. While it is not specifically designed for cabinet making, it can still be effectively used for various tasks in the cabinet making process. A steel square is typically made of durable steel and consists of two arms, one longer than the other, that meet at a right angle. It is used to mark and measure angles, check for squareness, and ensure accurate and precise cuts. These features make it an essential tool for cabinet making. When building cabinets, a steel square can be used to determine and mark the correct angles and measurements for cutting and joining the cabinet components, such as the panels, shelves, and doors. It can help ensure that the cabinet is square and properly aligned, resulting in a well-built and structurally sound piece of furniture. Additionally, a steel square can be used to check the squareness of corners and joints, ensuring that they are perfectly 90 degrees. This is crucial for achieving a professional and seamless finish in cabinet making. Although there are specialized tools available for specific tasks in cabinet making, a steel square is a versatile and cost-effective option that can be used for a wide range of measurements and marking purposes. It is a tool that is commonly found in the toolbox of both amateur and professional cabinet makers alike.

Send your message to us

Hot Rolled Structure Steel Square Bar with Many sizes

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 3000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords