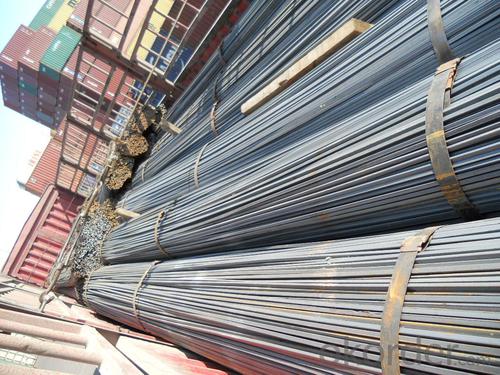

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

OKorder is offering Hot Rolled Square Steel Bars with Cr A36, Q235, SS400 at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

-The Square Steel is normally used as structure steel.

-Row material for other structure steel like steel angles, channels, I-beams, H-beams, etc…

-Row material for steel pipes.

Product Advantages:

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400 are durable, strong, and resists corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (7-10 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

-Standard: GB,

-Grade: Q235 or equivalent.

Chemical Composition:

Standard | Grade | Element (%) | ||||

GB | Q235B | C | Mn | S | P | Si |

0.12~0.20 | 0.30~0.70 | ≤0.045 | ≤0.045 | ≤0.30 | ||

Measures of Hot Rolled Square Steel Bars with Cr A36, Q235, SS400:

(Section of HR Square Bar)

-Length of a side and Theoretical weight of Square Bar.

Length of a side(mm) | Theoretical weight(kg/m) | Length of a side(mm) | Theoretical weight(kg/m) |

6 | 0.283 | 32 | 8.04 |

7 | 0.385 | *33 | 8.55 |

8 | 0.502 | 34 | 9.07 |

9 | 0.636 | *35 | 9.62 |

10 | 0.785 | 36 | 10.17 |

11 | 0.950 | 38 | 11.24 |

12 | 1.13 | 40 | 12.56 |

13 | 1.33 | 42 | 13.85 |

14 | 1.54 | 45 | 15.90 |

15 | 1.77 | 48 | 18.09 |

16 | 2.01 | 50 | 19.63 |

17 | 2.27 | 53 | 22.05 |

18 | 2.54 | *55 | 23.6 |

19 | 2.82 | 56 | 24.61 |

20 | 3.14 | *58 | 26.4 |

21 | 3.46 | 60 | 28.26 |

22 | 3.80 | 63 | 31.16 |

*23 | 4.15 | *65 | 33.17 |

24 | 4.52 | *68 | 36.3 |

25 | 4.91 | 79 | 38.49 |

26 | 5.30 | 75 | 44.16 |

*27 | 5.72 | 80 | 50.24 |

28 | 6.15 | 85 | 56.72 |

*29 | 6.60 | 90 | 63.59 |

30 | 7.06 | 95 | 70.85 |

*31 | 7.54 | 100 | 78.50 |

Notes:

1, The theoretical weights in the list, base on the density of 7.85 g/cm3.

2, Formula for theoretical weight of Square bar: a(length of a side) * a * 0.00785

3, The numbers with *mean that they are not regular or we don’t offer them.

-Regular length of Square Bar:

Steel | Length of a side (mm) | Length of steel (m) |

Normal steel | < 25 | 4~10 |

> 25 | 3~9 | |

Steel of high quality | All measure | 2~6 |

Tool steel >75 | 1~6 |

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: What makes stainless steel stainless?

- Q: Can a steel square be used for checking the plumbness of a wall stud?

- Checking the plumbness of a wall stud cannot be done using a steel square. A steel square, which is also known as a carpenter's square, is primarily utilized for measuring and marking right angles in woodworking projects. It is not constructed or calibrated for the purpose of checking plumbness. In order to determine if a wall stud is plumb, a level or plumb bob is typically employed. These tools are specially designed to guarantee vertical alignment and are more precise for this specific task.

- Q: Can a steel square be used for checking the alignment of a jointer fence?

- Yes, a steel square can be used for checking the alignment of a jointer fence.

- Q: Can a steel square be used for stair railing installation?

- Yes, a steel square can be used for stair railing installation. The steel square can be used to accurately measure and mark angles, ensuring precise and straight cuts for the railing components. It can also be used to check the levelness and alignment of the railing during the installation process.

- Q: How do you use a steel square to measure and mark 112.5-degree angles?

- To use a steel square to measure and mark a 112.5-degree angle, you will need to follow a specific procedure. Here's how you can do it: 1. Begin by placing the steel square on a flat surface or workpiece, ensuring that it is stable and secure. 2. Locate the 45-degree angle on the steel square. This angle is formed where the long arm and the short arm of the square meet. 3. Set the long arm of the square on the surface, making sure it is aligned with the reference line or edge you want to measure and mark the angle from. 4. Rotate the steel square slightly towards the left until the short arm aligns with the desired angle. In this case, you want to measure and mark a 112.5-degree angle, so you need to rotate the square approximately 2.5 degrees more than the 45-degree angle. 5. Once you have adjusted the steel square to the appropriate angle, hold it firmly in place to ensure accuracy. 6. Using a pencil or a scribe, carefully mark the desired angle along the edge of the steel square or on the workpiece. 7. Double-check your measurement and marking to ensure accuracy before proceeding with any further steps. By following these steps, you can effectively use a steel square to measure and mark a 112.5-degree angle. Remember to handle the square carefully and double-check your measurements to achieve precise results.

- Q: What are some common uses of a steel square in metal fabrication?

- Some common uses of a steel square in metal fabrication include measuring and marking straight lines, checking right angles, setting up precise angles for cutting or welding, and ensuring accurate layouts and dimensions for various metalwork projects.

- Q: How do you use a steel square for marking and cutting tenons with shoulders?

- For marking and cutting tenons with shoulders, the following steps should be followed when using a steel square: 1. Before starting, make sure that the steel square is clean and free from rust or debris. This will guarantee accurate measurements and markings. 2. To begin, measure the width of the tenon on the piece of wood being worked on. Place the steel square on the wood's edge, aligning the inside edge of the square with the desired width measurement. 3. Once the square is aligned, use a pencil or marking knife to mark the tenon's width on the wood. It is important to mark both sides of the wood for accuracy. 4. Next, determine the tenon's depth. Measure the desired depth on the wood's end, perpendicular to the width marking. This will be the length of the shoulder on each side of the tenon. 5. Position the steel square on the wood's end, aligning the inside edge of the square with the depth measurement. Use a pencil or marking knife to mark the shoulder depth on each side of the wood. 6. After marking the tenon's width and shoulder depth, proceed to cut it. Use a saw to carefully cut along the width marking, stopping at the shoulder depth marking. Repeat this on the other side of the wood to create the tenon. 7. Once the tenon is cut, refine the shoulders using a chisel or shoulder plane. Carefully remove any excess wood to create a clean and flat surface for the shoulders. 8. Finally, check the fit of the tenon by inserting it into the corresponding mortise or joint. Make any necessary adjustments to the width or shoulder depth until the tenon fits snugly. By utilizing a steel square, precise measurements and markings can be ensured when marking and cutting tenons with shoulders. This will result in a sturdy and accurate joint that fits together seamlessly.

- Q: How do you use a steel square to measure and mark compound angles?

- In order to measure and mark compound angles using a steel square, there are several steps that need to be followed. To begin, it is important to understand that a steel square, which is also referred to as a framing square, consists of two arms that meet at a right angle. One of the arms is longer, known as the blade, while the other is shorter and referred to as the tongue. The blade typically contains markings and measurements for various angles. To start the process, you must first determine the specific compound angle that you wish to measure and mark. This involves identifying the two individual angles that make up the compound angle. For instance, if you want to measure a compound angle that consists of 45 degrees and 30 degrees, you will need to measure and mark each of these angles separately. Next, position the steel square onto the material that you intend to mark. Place the tongue against one side of the material and align the blade with the other side. It is important to ensure that the square is firmly pressed against the material and that the blade is parallel to the tongue. Afterward, rotate the steel square until the desired angle is aligned with the material. Utilize the measurements and markings on the blade to determine the correct angle. For example, if you wish to measure a 45-degree angle, align the marking on the blade that indicates 45 degrees with the material. Once the first angle is properly aligned, use a pencil or marking tool to mark the material along the blade of the steel square. This will create a line that indicates the first angle. Proceed to repeat the process for the second angle of the compound angle. Rotate the steel square once again until the desired angle is aligned with the material, utilizing the measurements and markings on the blade. Mark the material along the blade to indicate the second angle. The point where the two marked lines intersect represents the compound angle that you wish to achieve. You can now use these marks as a guide for cutting, joining, or any other application where a compound angle is necessary. It is important to remember that using a steel square to measure and mark compound angles requires accuracy in aligning the square and reading the measurements on the blade. With practice and experience, your proficiency in effectively using a steel square for compound angles will improve.

- Q: How do you use a steel square for marking and cutting angled bridle joints?

- To use a steel square for marking and cutting angled bridle joints, follow these steps: 1. Begin by determining the desired angle for the bridle joint. This can be done by referring to the project plans or design specifications. 2. Place the steel square against the edge of the workpiece, aligning it with the edge where the bridle joint will be cut. 3. Adjust the angle of the steel square to match the desired angle for the bridle joint. Make sure the square is firmly held against the workpiece. 4. Use a pencil or a marking knife to trace along the edge of the steel square, marking the angle onto the workpiece. This line will serve as a guide for cutting the joint. 5. Once the angle is marked, use appropriate tools such as a saw or chisel to cut along the marked lines, creating the angled bridle joint. Remember to work carefully and precisely to ensure accurate cuts and a well-fitting joint.

- Q: What are the different ways to read angles on a steel square when working with metal?

- When working with metal, there are multiple ways to read angles on a steel square. Here are a few common methods: 1. Degree Scale: Many steel squares have a degree scale engraved on the blade. This scale allows you to directly read the angle in degrees by aligning the desired angle with the reference line on the blade. 2. Protractor: Using a protractor in conjunction with a steel square can provide more precise angle measurements. Place the protractor against the blade of the square and align the reference line with the desired angle. Read the angle measurement directly from the protractor. 3. Vernier Scale: Some advanced steel squares may have a vernier scale. This scale provides even more precise angle readings. Align the desired angle with the reference line and read the corresponding value on the vernier scale. The vernier scale allows for more accurate measurements by providing additional subdivisions. 4. Digital Angle Finder: For those who prefer digital tools, a digital angle finder can be used in conjunction with a steel square. Place the square against the workpiece and then use the digital angle finder to measure the angle. This tool provides precise measurements and can be especially helpful when working with complex angles. 5. Combination Square: A combination square is a versatile tool that includes a ruler, a level, and an adjustable blade. By adjusting the blade to the desired angle, you can easily read the angle measurement on the scale provided on the blade. Remember, regardless of the method used, it is crucial to ensure that the steel square is securely placed against the workpiece to obtain accurate angle readings.

- Q: Can a steel square be used for gazebo layout and construction?

- Yes, a steel square can be used for gazebo layout and construction. A steel square, also known as a framing square, is a versatile tool used by carpenters and builders to ensure accurate and precise measurements and angles during construction projects. It consists of two arms, one longer than the other, forming a right angle. The longer arm is also marked with a graduated scale for easy measurement. When it comes to gazebo layout and construction, a steel square can be incredibly useful. It can be used to mark and layout the foundation, ensuring that the corners are square and the angles are accurate. Additionally, it can be used to measure and mark the lengths and angles of the various components of the gazebo, such as the posts, beams, and rafters. Furthermore, a steel square can help in checking and adjusting the squareness of the gazebo structure during construction. By placing the square against the corners and edges of the gazebo, any discrepancies in the angles can be easily identified and corrected. Overall, a steel square is a valuable tool for gazebo layout and construction, providing accuracy, precision, and ensuring that the structure is built correctly.

Send your message to us

Hot Rolled Square Steel Bars with Cr A36, Q235, SS400

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords