hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

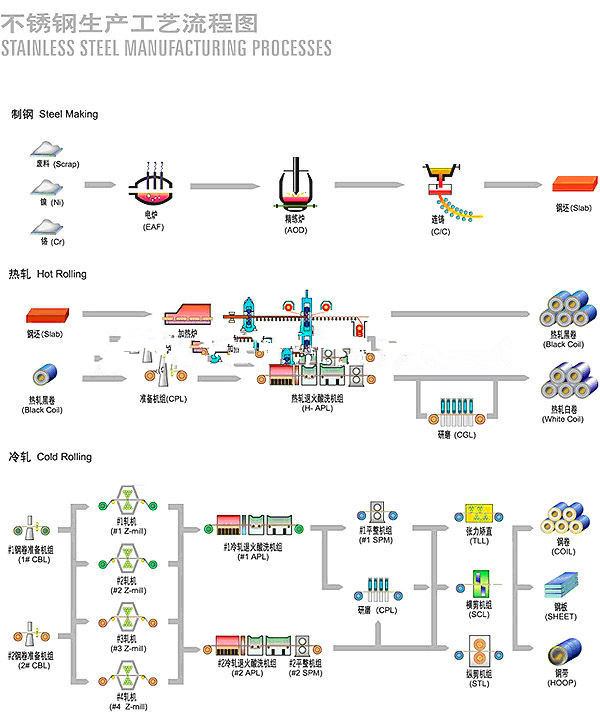

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:88.9*5.49 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

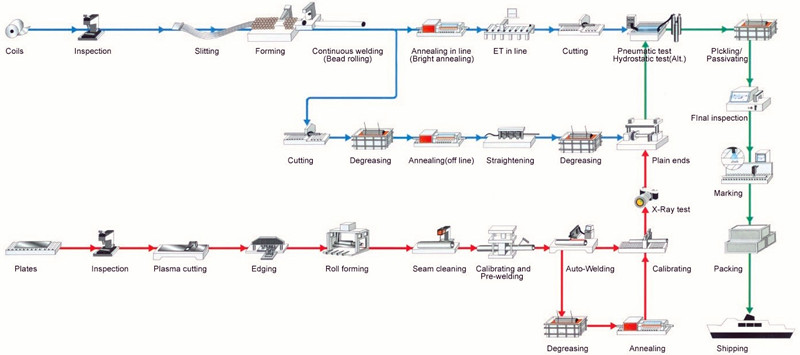

A series of photos

A series of pictures

- Q: What is the difference between 304Ti and 316Ti stainless steel pipes?

- The main difference between 304Ti and 316Ti stainless steel pipes is their composition and corrosion resistance properties. 304Ti is a variant of 304 stainless steel, with the addition of titanium to improve its high-temperature strength and resistance to sensitization. On the other hand, 316Ti is a variant of 316 stainless steel, with the addition of titanium to enhance its resistance to corrosion, particularly in environments with high chloride levels. Overall, while both alloys offer good corrosion resistance, 316Ti is generally considered to have superior resistance to corrosion and pitting compared to 304Ti.

- Q: Can stainless steel pipes be used for air conditioning systems?

- Indeed, air conditioning systems can utilize stainless steel pipes. Given its durability and resistance to corrosion, stainless steel proves to be a fitting material for a wide range of applications, including air conditioning systems. With their exceptional resistance to oxidation and rust, stainless steel pipes guarantee prolonged use and ward off any potential leakage. Moreover, these pipes possess the capacity to withstand elevated temperatures and pressure, rendering them perfect for integration within air conditioning systems.

- Q: Are stainless steel pipes resistant to scaling and pitting?

- Yes, stainless steel pipes are highly resistant to scaling and pitting due to their inherent corrosion-resistant properties.

- Q: What is the difference between seamless and LSAW stainless steel pipes?

- Different industries commonly use seamless and LSAW stainless steel pipes. The manufacturing process and resulting structural characteristics distinguish these two types of pipes. Seamless stainless steel pipes are produced without any seams or welds. Manufacturers achieve this by piercing a solid cylindrical billet and extruding it to create a hollow tube. This technique ensures a uniform cross-section, resulting in a smooth and consistent inner and outer surface. The absence of welds eliminates potential weak points, enhancing the overall strength and integrity of the pipe. Seamless pipes are known for their superior corrosion resistance and are often preferred in critical applications where leakage must be avoided. In contrast, LSAW stainless steel pipes are formed by bending and welding a steel plate or coil into a cylindrical shape. The welding process involves passing an electric arc through the steel plate and the welding filler material, creating a visible seam on the pipe's exterior. LSAW pipes are commonly used in applications requiring large diameters and thick walls, such as oil and gas transportation. They can be produced in longer lengths and with larger diameters compared to seamless pipes. Seamless stainless steel pipes are generally more expensive to manufacture than LSAW pipes due to their complex production process. However, their seamless construction offers superior performance and reliability, making them the preferred choice for critical applications. On the other hand, LSAW pipes provide a cost-effective solution for large-scale projects where the visible seam is not a concern. To summarize, the main differences between seamless and LSAW stainless steel pipes lie in their manufacturing process, structural characteristics, and cost. Seamless pipes are made without seams or welds, providing excellent corrosion resistance and strength. LSAW pipes, on the other hand, are created by bending and welding a steel plate, offering a cost-effective solution for large-scale projects. The choice between these two types of pipes depends on the specific requirements of the application and the desired balance between cost and performance.

- Q: Where is the difference between seamless steel pipe and welded pipe?

- The steel tube is a hollow steel strip, used as pipe conveying fluid, such as oil, gas, water, gas, steam, in addition, the bending and torsional strength of the same, the weight is light, so it is widely used in the manufacture of machinery parts and engineering structures. It is also used to produce all kinds of conventional weapons, guns, shells and so on.

- Q: What are the different types of stainless steel pipe couplings?

- In the market, one can find a variety of stainless steel pipe couplings, each offering their own unique features and functions. Some commonly used types are as follows: 1. Compression couplings: These couplings are designed to securely connect pipes by compressing their ends together using a compression nut. They are suitable for both rigid and flexible pipe systems and can be easily installed. 2. Flanged couplings: These couplings have flanges on both ends, which can be bolted together to create a strong and leak-proof connection. They are commonly used in industrial applications that involve high pressures and temperatures. 3. Grooved couplings: These couplings consist of two segments that grip the pipe ends when tightened, creating a reliable and flexible connection. They are frequently used in fire protection systems and HVAC applications, as they are easy to install and can withstand vibration and movement. 4. Threaded couplings: These couplings have internal threads that allow them to be screwed onto the pipe ends. They are commonly used in low-pressure applications and can be easily assembled and disassembled. 5. Quick connect couplings: These couplings have a quick-connect mechanism that enables easy and rapid installation without the need for tools or additional components. They are commonly used in plumbing and irrigation systems. 6. Welded couplings: These couplings require welding the pipe ends together to create a permanent and strong connection. They are commonly used in high-pressure and high-temperature applications where a robust joint is essential. To ensure the appropriate selection of a stainless steel pipe coupling, it is important to consider the specific requirements of the application, such as operating conditions, pipe material, and system design. Seeking advice from a professional or referring to industry standards can help in making the right choice.

- Q: How do you prevent backflow in stainless steel pipes?

- To prevent backflow in stainless steel pipes, there are a few key measures that can be taken. 1. Install a backflow preventer: This is a mechanical device that is installed in the pipe system to ensure that water flows in one direction and prevents any backflow. There are different types of backflow preventers available, such as check valves, double check valves, and reduced pressure zone devices. The selection of the appropriate backflow preventer depends on the specific requirements of the system and local codes and regulations. 2. Regular maintenance and inspection: It is important to regularly inspect the backflow preventer and ensure it is functioning properly. Any signs of wear or damage should be addressed immediately to prevent potential backflow issues. Regular maintenance can also include cleaning and replacing any worn-out parts to ensure optimal performance. 3. Pressure regulation: Maintaining proper pressure in the stainless steel pipes can also help prevent backflow. High pressure can cause water to flow in the opposite direction, leading to backflow. By installing pressure regulators or pressure-reducing valves, the water pressure can be controlled and maintained within the recommended range. 4. Air gaps: Incorporating air gaps in the system can provide an additional layer of protection against backflow. An air gap is a physical separation between the water source and the point of use, ensuring that there is no direct connection that could allow backflow to occur. 5. Adequate system design: Proper system design is crucial in preventing backflow. By ensuring that the stainless steel pipes have the correct sizing, appropriate slope, and proper connections, the risk of backflow can be minimized. Additionally, locating the backflow preventer in an easily accessible area can facilitate regular maintenance and inspection. By implementing these preventive measures, the risk of backflow in stainless steel pipes can be significantly reduced, promoting the safe and efficient flow of water in the system.

- Q: Are stainless steel pipes suitable for hydraulic applications?

- Yes, stainless steel pipes are suitable for hydraulic applications. Stainless steel is known for its excellent corrosion resistance, which makes it an ideal choice for hydraulic systems that may come into contact with various fluids. Stainless steel pipes have high strength and durability, allowing them to withstand high pressure and temperature conditions commonly encountered in hydraulic systems. Additionally, stainless steel pipes offer excellent dimensional stability and can maintain their shape and integrity even under extreme operating conditions. Due to their resistance to corrosion, stainless steel pipes also provide a longer service life compared to other materials, reducing the need for frequent replacements and maintenance. Overall, stainless steel pipes are a reliable and efficient choice for hydraulic applications.

- Q: What is the maximum length of a stainless steel pipe that can be manufactured?

- The maximum length of a stainless steel pipe that can be manufactured is typically determined by practical limitations such as transportation and handling capabilities. In general, stainless steel pipes can be manufactured in lengths ranging from a few feet to several hundred feet. However, the exact maximum length can vary depending on factors such as the diameter and thickness of the pipe, as well as the manufacturing capabilities of the specific company or facility. It is important to consult with the manufacturer or supplier to determine the maximum length available for a particular stainless steel pipe.

- Q: What is the difference between 430 and 316 stainless steel pipes?

- The main difference between 430 and 316 stainless steel pipes is their composition and properties. 430 stainless steel is a ferritic stainless steel, which means it contains a higher percentage of chromium and has a lower nickel content compared to 316 stainless steel. This makes 430 stainless steel less corrosion resistant and less suitable for applications in highly corrosive environments. On the other hand, 316 stainless steel is an austenitic stainless steel, which contains higher amounts of chromium and nickel, providing excellent corrosion resistance and making it suitable for use in marine environments and industries with high levels of exposure to chemicals and salt. Additionally, 316 stainless steel has superior strength and heat resistance compared to 430 stainless steel.

Send your message to us

hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords