Hot Rolled Plate Steel 2016 New Desigh With Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

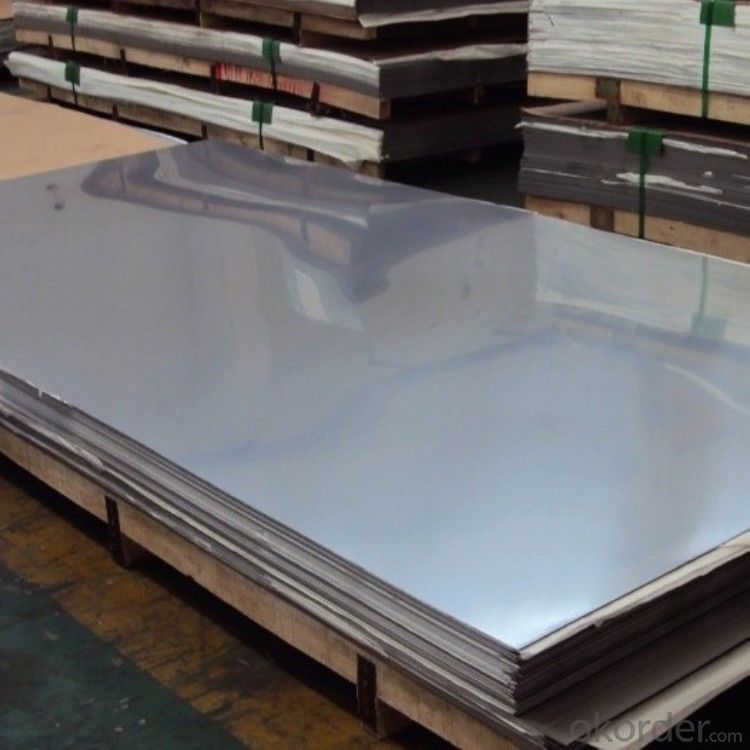

DESCRIPTION:

GRADE: SS400, ASTM A36, A572, ST37,ST52, Q195, Q215, Q235,Q345, S235JR etc.

STANDARD: GB/T709-2006, ASTM A36, JIS G3101, DIN EN 10025, SAE 1045, ASTM A570

SPEC: 1)Width: 600-2500mm or 1000,1050,1250,1500,1800,2000mm

2)Thickness:1.5mm-200mm or as customers’ special requirements;

3)Length: 2-12m or as customers’ special requirements

PACKING:

1.Big thickness:by bulk vessel

2.Small thickness:packed by steel strips and shipped by container

3.According to the requirements of customers'

TRADE TERMS :FOB, CFR, CIF

DETAILED PICTURES FOR STEEL COILS

FAQ:

Q:Do you have OEM service?

A: Yes.Variety of products size,quality and quantity can be customized according to your need.

Q:Could you support free sample?

A:Yes.We can supply FREE samples.But the delivery charges will be covered by our customers.

Q:How about the delivery time?

A:Within 15-30days after receiving the deposit or L/C at sight.

- Q: Are the steel sheets resistant to scratching or abrasion?

- Yes, steel sheets are highly resistant to scratching or abrasion. Steel is known for its exceptional durability and strength, making it resistant to various forms of damage, including scratches and abrasions. The smooth and hard surface of steel sheets makes them less susceptible to scratches caused by sharp objects or rough surfaces. Additionally, the strong molecular structure of steel prevents it from easily wearing down or getting scratched, ensuring its longevity even in high-traffic or demanding environments. Overall, steel sheets are an excellent choice when it comes to resistance against scratching or abrasion.

- Q: What is the difference between a hot rolled and cold rolled galvanized steel sheet?

- The main difference between a hot rolled and cold rolled galvanized steel sheet lies in the manufacturing process and the resulting properties of the finished product. Hot rolled galvanized steel sheets are made by heating a large steel slab or billet above its recrystallization temperature, which is typically around 1700°F (926°C). This high temperature allows the steel to be easily shaped and formed into the desired thickness and dimensions. The hot rolling process also helps to refine the grain structure of the steel, resulting in improved mechanical properties and a more uniform distribution of alloying elements. On the other hand, cold rolled galvanized steel sheets are manufactured at room temperature by passing the hot rolled sheet through a series of rollers that compress and shape the material. This process not only reduces the thickness of the sheet but also increases its tensile strength and improves its surface finish. Cold rolling also allows for tighter tolerances and more precise dimensions, making it suitable for applications that require high precision and consistency. In terms of properties, hot rolled galvanized steel sheets tend to have a rougher surface finish due to the high temperature processing. However, they are generally more ductile and easier to form or bend compared to cold rolled sheets. Hot rolled sheets also have a slightly thicker oxide layer on the surface, which provides some additional corrosion resistance. Cold rolled galvanized steel sheets, on the other hand, have a smoother and more polished surface finish. They are typically thinner and have a higher strength-to-weight ratio compared to hot rolled sheets. The cold rolling process also results in a more homogeneous microstructure, which can improve the overall mechanical properties of the steel, such as hardness and toughness. Overall, the choice between hot rolled and cold rolled galvanized steel sheet depends on the specific requirements of the application. Hot rolled sheets are often preferred for applications that require easy formability and a rougher surface finish, while cold rolled sheets are favored for their higher strength, tighter tolerances, and smoother surface finish.

- Q: Can steel sheets be used for food processing applications?

- Yes, steel sheets can be used for food processing applications. Stainless steel sheets are commonly used in the food industry due to their corrosion resistance, durability, and hygienic properties. They can be used for various applications such as food preparation surfaces, countertops, storage containers, and equipment components.

- Q: Can steel sheets be used for security doors and windows?

- Yes, steel sheets can be used for security doors and windows. Steel is a strong and durable material that provides enhanced security and protection against break-ins and forced entry. It is commonly used in the construction of security doors and windows due to its strength and resistance to impact and tampering.

- Q: Can steel sheets be laminated with other materials?

- Yes, steel sheets can be laminated with other materials. Lamination is a process where multiple layers of materials are bonded together to create a composite structure. Steel sheets can be laminated with various materials such as plastics, polymers, wood, or other metals, depending on the desired properties and application requirements. This lamination process enhances the strength, durability, and overall performance of the steel sheets.

- Q: How are steel sheets protected during transportation by sea?

- To ensure the safety and prevent damage of steel sheets during transportation by sea, various measures are taken. One commonly used method involves applying a protective coating to the sheets. This coating acts as a barrier against moisture and saltwater, which are the main culprits behind corrosion during sea transportation. The coating can be a temporary solution, such as a layer of oil or wax, or a more permanent option, such as a layer of paint or zinc. Moreover, steel sheets are often bundled or placed in shipping containers for added protection. These bundles are secured with straps or wires to prevent movement and potential damage in rough sea conditions. The shipping containers themselves are designed to withstand the challenges of sea transportation and shield the steel sheets from exposure to the elements. Additionally, the sheets may be wrapped in plastic or other waterproof materials to provide an extra layer of defense against moisture. This helps prevent direct contact with seawater or rain, thus reducing the risk of corrosion. During the loading and unloading processes, proper handling techniques are employed to minimize the risk of damage. Cranes or forklifts are carefully used to lift and move the steel sheets, ensuring that they are not dropped or subjected to excessive force that could cause dents or bends. Overall, a combination of protective coatings, secure packaging, and proper handling techniques is utilized to safeguard steel sheets during sea transportation. This reduces the likelihood of damage and ensures that they reach their destination in optimal condition.

- Q: Can steel sheets be used for solar panel support structures?

- Yes, steel sheets can be used for solar panel support structures. Steel is a strong and durable material that can provide the necessary structural support for solar panels. It is widely used in the construction industry due to its high strength-to-weight ratio and resistance to corrosion, making it suitable for outdoor applications such as solar panel installations.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets varies depending on the specific grade and thickness of the steel. However, it typically ranges from 250 to 400 megapascals (MPa).

- Q: Are steel sheets suitable for manufacturing HVAC grilles?

- Yes, steel sheets are suitable for manufacturing HVAC grilles. Steel is a popular material choice for HVAC grilles due to its strength, durability, and versatility. It is able to withstand the high temperatures and air pressures often encountered in HVAC systems. Steel sheets can be easily formed into various shapes and sizes to meet specific grille designs and requirements. Additionally, steel is resistant to corrosion, which is important for maintaining the longevity and performance of HVAC grilles in both indoor and outdoor environments. Overall, steel sheets provide the necessary properties and characteristics needed for manufacturing high-quality HVAC grilles.

- Q: Can steel sheets be used for manufacturing storage tanks?

- Yes, steel sheets can be used for manufacturing storage tanks. Steel is a commonly used material in tank fabrication due to its strength, durability, and resistance to corrosion. It can be easily formed into sheets and welded together to create storage tanks of various sizes and shapes.

Send your message to us

Hot Rolled Plate Steel 2016 New Desigh With Cheap Price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords