Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army:

With Gi as base metal,after pretreatmet (degrease and chemical treatment) and liquid dope with several Layers of color,then after firing and cooling,finally the plate steel is called pre-painted galvanized steel ( PPGI) .Pre-painted galvanized steel is good capable of decoration ,molding,corrosion resistance

2.Main Features of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent heat resistance performance

• High strength

• Good formability

• Good visual effect

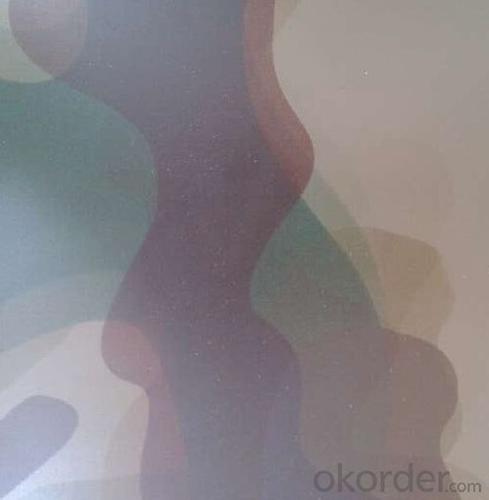

3.Print Prepainted Galvanized Steel Coil Wooden Pattern for Army Images

4.Print Prepainted Galvanized Steel Coil Wooden Pattern for Army Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: DX51D CGCC CS

Thickness: 0.13mm~3.0mm,

Width: 1250,600-1250mm

Coil weight:3-12 MT

Coil ID:508/610mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

5.FAQ of Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

We have organized several common questions for our clients,may help you sincerely:

1.How do you control your quality

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

2.How long we will receive the goods ?

After receiving your deposit or workable lc ,our normal shipment date is 15-20days,and it takes around 28 days to reach your port of destination. But is up to different destination

3. What is your moq

Normally our moq is 25mt per size ,but it is up to different size.

- Q: Can steel sheets be used for insulation purposes?

- No, steel sheets cannot be used for insulation purposes as they conduct heat and electricity, rather than providing insulation against them.

- Q: Can the steel sheets be easily cleaned?

- Yes, steel sheets can be easily cleaned.

- Q: What are the different storage methods for steel sheets?

- Steel sheets can be stored in various ways, depending on specific requirements and available space. Here are some commonly used storage methods: 1. For small quantities or lighter sheets, a basic method is flat storage, where sheets are placed horizontally on a flat surface like the floor or metal racks. 2. Vertical storage is another option, which involves placing sheets against a wall or using specially designed vertical racks. This not only saves floor space but also allows for easy access and identification of different sheet sizes. 3. To store long and heavy sheets, cantilever racks with horizontal arms extending from a vertical column provide excellent support. These racks facilitate easy loading and unloading using forklifts or cranes. 4. Roll-out racks, equipped with rollers or ball bearings, work like drawers, allowing steel sheets to be easily rolled in and out. This method is ideal when frequent access to different sheets is required, as it offers good visibility and convenient retrieval. 5. A-frame racks, featuring angled arms resembling the letter "A," are suitable for storing large quantities of steel sheets. This method provides easy access while ensuring organization. 6. For maximum storage capacity and efficiency, automated storage and retrieval systems (AS/RS) come into play. These computer-controlled systems can be designed as vertical lift modules or robotic systems, automatically storing and retrieving steel sheets. When choosing a storage method, it's crucial to consider factors such as sheet size, weight, accessibility, and safety. Additionally, adequate measures should be taken to protect the sheets from moisture, dust, and other environmental factors that could potentially impact their quality.

- Q: Can steel sheets be used for fencing?

- Yes, steel sheets can be used for fencing. Steel sheets are durable and provide a strong barrier, making them a popular choice for fencing in various settings such as residential, commercial, and industrial properties.

- Q: What is the typical flexural strength of a steel sheet?

- The typical flexural strength of a steel sheet depends on various factors such as the grade and thickness of the steel. However, it is generally high and can range from 300 to 1,500 megapascals (MPa) or more.

- Q: Can steel sheets be used for manufacturing musical instruments?

- Yes, steel sheets can be used for manufacturing certain musical instruments such as steel drums, steel guitars, and some percussion instruments.

- Q: Can steel sheets be used for electrical enclosures?

- Yes, steel sheets can be used for electrical enclosures. Steel is a commonly used material due to its durability, strength, and ability to provide electromagnetic shielding. It is suitable for protecting electrical components from external factors such as moisture, dust, and impact while also providing a safe and secure environment for the electrical equipment.

- Q: What is the difference between a pre-annealed and full hard steel sheet?

- A pre-annealed steel sheet refers to a steel sheet that has undergone the annealing process, which involves heating the steel to a specific temperature and then cooling it slowly. This process helps to relieve internal stresses in the steel and improve its ductility and workability. As a result, pre-annealed steel sheets possess higher levels of formability and are easier to shape and manipulate compared to their non-annealed counterparts. On the other hand, a full hard steel sheet has not undergone the annealing process and retains its original hardness and strength. Full hard steel sheets are typically used in applications that require high strength, durability, and resistance to deformation. These sheets are more rigid and less ductile, making them suitable for applications where shape retention and stiffness are critical, such as in automotive components or structural supports. In summary, the main difference between pre-annealed and full hard steel sheets lies in their formability and strength characteristics. Pre-annealed steel sheets are more malleable and easier to shape, while full hard steel sheets offer higher strength and rigidity. The choice between the two depends on the specific requirements of the application and the desired balance between formability and strength.

- Q: What are the different types of steel sheets available?

- There are various types of steel sheets available, including hot rolled, cold rolled, galvanized, stainless, and coated steel sheets.

- Q: Can steel sheets be used for reinforcing concrete structures?

- Yes, steel sheets can be used for reinforcing concrete structures. Steel sheets, also known as steel reinforcement bars or rebars, are commonly used in construction to provide tensile strength and enhance the durability of concrete structures. These sheets are placed within the concrete to bear the tensile forces that concrete alone cannot withstand. They help prevent cracking and improve the overall strength and integrity of the structure.

Send your message to us

Print Prepainted Galvanized Steel Coil Wooden Pattern for Army

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 12 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords