Hot Rolled Oil Tank_Carbon Boiler Steel Plate_Sheet A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Prime Hot Rolled Carbon Steel Plate_Sheet Dimensions

Thickness:0.6-200mm

Width:1000-4000mm

MOQ: 1 ton

Certificate:ISO,SGS

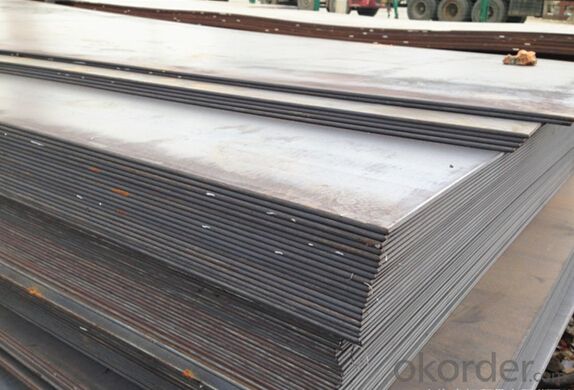

Specification of Hot Rolled Carbon Steel Plate_Sheet

Commodity | Prime hot rolled carbon steel plate / sheet dimensions |

Thickness | 0.6-200mm |

Width | 1000-4000mm |

Length | as custom's request |

Technique | Cold rolled or hot rolled mild steel plate |

Surface treatment | Bare, galvanized coated or as customer's requirements. |

Standard | ASTM,EN,GB,JIS |

Material | A283Gr.D/A573Gr.65,A516Gr65,A516Gr70,A284Gr.D SS400,SS300,CCSB A36,A32,LRA32,LRB,Q235 SAE1010,SAE1020,SAE1045,Q195,Q235,Q345,SS400,ASTM A36,E235B mild steel plate |

Usage | the mild steel plate will used in home appliances construction, machinery manufacturing, container manufacturing, shipbuilding, bridges, etc. |

Terms of Payment | 30% T/T as deposit and 70% T/T balance againest B/L copy. |

Delivery Detail | Within 3-15 days after receipt of deposited for the mild steel plate |

CNBM Introduction of the Hot Rolled Carbon Steel Plate_Sheet Supplier

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service |

|

Advantages

|

|

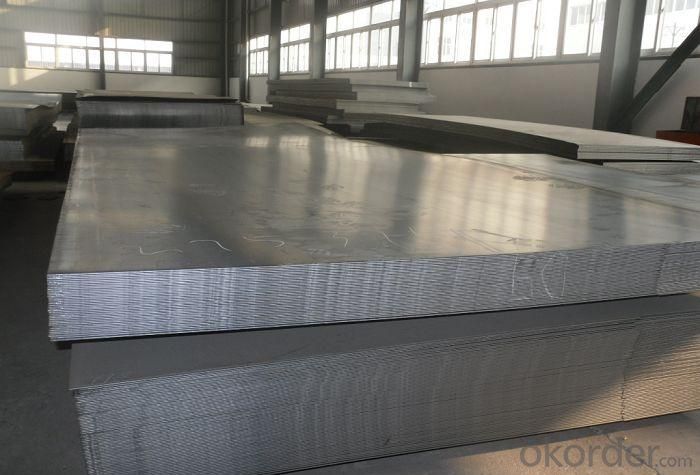

Packaging & Delivery of the Hot Rolled Carbon Steel Plate_Sheet

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different grades and specifications of special steel?

- Special steel refers to a category of steel that is specifically designed to possess enhanced properties for specific applications. There are various grades and specifications of special steel available, each tailored to meet specific requirements. Some common grades include tool steel, stainless steel, high-speed steel, and alloy steel. These grades are further categorized based on their composition, strength, hardness, corrosion resistance, and other properties. Additionally, special steel specifications may vary depending on the industry or application, such as aerospace, automotive, construction, or oil and gas. Overall, the diverse range of grades and specifications in special steel allows for customized solutions to meet specific performance demands.

- Q: What are the main applications of special steel in the power transmission industry?

- Special steel is widely used in the power transmission industry for various applications. One of the main applications is in the manufacturing of power transmission components such as gears, shafts, and couplings, where special steel's high strength and durability are essential for transmitting power efficiently. Additionally, special steel is also used in the construction of power transmission towers and poles, providing structural integrity and resistance against harsh environmental conditions. Overall, the main applications of special steel in the power transmission industry revolve around its ability to enhance performance, reliability, and longevity of power transmission systems.

- Q: How does special steel contribute to the defense and security industry?

- Enhanced strength, durability, and resistance to extreme conditions are crucial attributes of special steel, playing a vital role in the defense and security industry. This type of steel is specifically designed to meet the industry's unique demands, ensuring military equipment and infrastructure can withstand challenging environments and threats. One significant contribution of special steel to the defense and security sector lies in its use for manufacturing armored vehicles and tanks. These vehicles require high-strength steel to protect military personnel from ballistic and explosive threats. Special steel provides the necessary toughness and resilience to withstand impacts, ensuring soldiers' safety on the battlefield. Moreover, special steel is instrumental in the production of naval vessels and submarines. The maritime environment poses significant challenges due to its corrosive nature and harsh weather conditions. By utilizing special steel, naval ships can be constructed with superior corrosion resistance, extending their lifespan and reducing maintenance costs. Additionally, special steel is vital for the production of military-grade weaponry and ammunition. The steel's high strength and durability ensure that firearms, missiles, and other weapons can withstand extreme forces and function reliably in critical situations. This reliability is of utmost importance in the defense and security industry, where weapon failure could have severe consequences. Furthermore, special steel contributes to the construction of critical defense infrastructure, including military bases, bunkers, and communication towers. Its ability to withstand extreme temperatures, high pressures, and other challenging conditions ensures the reliability and longevity of these structures, enhancing national security. In summary, special steel's unique properties, including high strength, durability, and resistance to extreme conditions, are essential in the defense and security industry. By incorporating this material into military equipment, vehicles, weaponry, and infrastructure, defense organizations can ensure the safety, reliability, and effectiveness of their operations, ultimately contributing to national security.

- Q: What are the different heat treatment processes used in special steel production?

- Some of the different heat treatment processes used in special steel production include annealing, tempering, quenching, and case hardening.

- Q: What is the role of special steel in the construction industry?

- Special steel plays a crucial role in the construction industry as it provides strength, durability, and resistance to various environmental factors. It is commonly used in the construction of high-rise buildings, bridges, and infrastructure projects. Special steel's unique properties, such as high tensile strength, corrosion resistance, and heat resistance, make it suitable for critical applications where standard steel may not suffice. It ensures the structural integrity and safety of construction projects, making it an essential material in the industry.

- Q: Can special steel be used in the automotive racing industry?

- Yes, special steel can be used in the automotive racing industry. Special steel alloys, such as high-strength or lightweight steels, can offer enhanced performance and durability, making them suitable for various racing applications. These steels can be used in the construction of engine components, chassis, suspension systems, and other critical parts, helping to improve speed, handling, and overall performance on the racetrack.

- Q: How does special steel contribute to the agricultural machinery industry?

- The agricultural machinery industry heavily relies on special steel to improve the overall efficiency, durability, and productivity of agricultural equipment. A major advantage of special steel in this industry is its exceptional strength and toughness, which allows for the production of robust and reliable machinery. Agricultural equipment, including tractors, combines, and harvesters, often faces intense operational conditions such as heavy loads, extreme temperatures, and exposure to corrosive elements. Special steel provides the necessary strength and resistance to withstand these challenging environments, ensuring optimal performance for extended periods. Furthermore, special steel alloys offer excellent wear resistance, enabling agricultural machinery to endure the abrasive nature of farming operations. This is especially crucial for components like blades, plows, and tillage tools, which are constantly exposed to soil, rocks, and other abrasive materials. By utilizing high-quality special steel, manufacturers can manufacture durable and long-lasting equipment, reducing maintenance requirements and improving the overall reliability of agricultural machinery. In addition, special steel allows for the development and construction of more efficient agricultural machinery. Thanks to its superior strength-to-weight ratio, special steel facilitates the production of lighter yet robust equipment. Consequently, this improves fuel efficiency, reduces energy consumption, and enhances maneuverability. Moreover, special steel's excellent machinability and formability enable manufacturers to create intricate and customized components, meeting specific agricultural needs and increasing machinery efficiency. Moreover, special steel contributes to the agricultural machinery industry by providing resistance to corrosion and rust. Agricultural equipment is often exposed to moisture, fertilizers, and chemicals, which can result in corrosion and degradation over time. Special steel alloys with corrosion-resistant properties, such as stainless steel, can significantly prolong the lifespan of machinery and reduce maintenance costs. In conclusion, special steel is indispensable for the agricultural machinery industry as it enhances the durability, efficiency, and productivity of equipment. Its strength, wear resistance, design flexibility, and corrosion-resistant properties make it the preferred choice for manufacturing high-quality machinery capable of withstanding the demanding conditions of agricultural operations.

- Q: What are the applications of special steel in the aerospace industry?

- Special steel has numerous applications in the aerospace industry due to its unique properties. It is extensively used in the manufacturing of aircraft components such as engine parts, landing gears, and structural elements. Special steel offers high strength, excellent corrosion resistance, and exceptional heat resistance, making it ideal for withstanding extreme conditions experienced during flight. Additionally, its lightweight nature helps reduce the overall weight of the aircraft, leading to improved fuel efficiency and performance. Overall, special steel plays a crucial role in enhancing the safety, durability, and efficiency of aerospace equipment.

- Q: How does special steel contribute to the defense aftermarket industry?

- Special steel plays a crucial role in the defense aftermarket industry by providing enhanced strength, durability, and resistance against extreme conditions. This allows for the manufacturing of high-performance components and equipment, such as armored vehicles, aircraft, and naval vessels. Special steel's unique properties enable the production of advanced weaponry and protective gear, ensuring the safety and effectiveness of defense operations. Additionally, its ability to withstand intense heat and pressure makes it ideal for critical applications like missile guidance systems and nuclear reactors. Overall, special steel is an essential material that drives innovation and strengthens the capabilities of the defense aftermarket industry.

- Q: Can special steel be used in the production of musical instruments?

- Yes, special steel can be used in the production of musical instruments. It is commonly used for strings, guitar frets, and some wind instrument components due to its specific acoustic properties and durability.

Send your message to us

Hot Rolled Oil Tank_Carbon Boiler Steel Plate_Sheet A36_A516 Gr.60_Gr.70

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords